Metal heat dissipation power battery pack structural design method and battery pack

A power battery pack and structural design technology, applied in the direction of batteries, secondary batteries, structural parts, etc., can solve the problems of battery pack structural deformation, weak load-bearing structure rigidity, thermal runaway, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0209] Take the design of a structure containing 25 18650 lithium-ion power battery packs as an example:

[0210] Power battery structure such as Figure 8 As shown, the overall size of the structure is 18cm×18cm×6.5cm, and 25 power batteries are evenly distributed in the cylinder; the power battery pack structure is made of aluminum alloy, and the heat-conducting silica gel sheet filled between the battery and the structure functions as insulation, heat conduction, and buffer And so on.

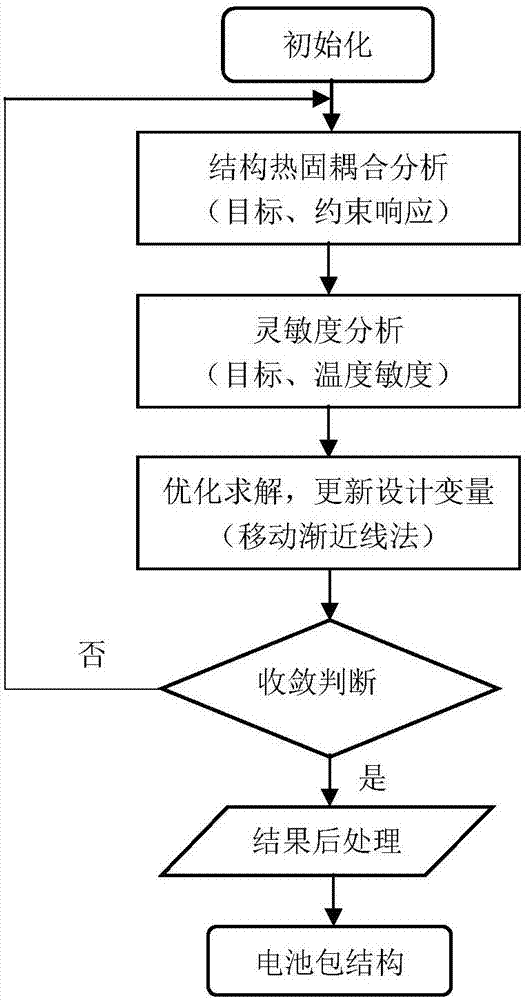

[0211] The overall flow of the power battery pack structure design method is as follows: figure 1 As shown, the specific steps are as follows:

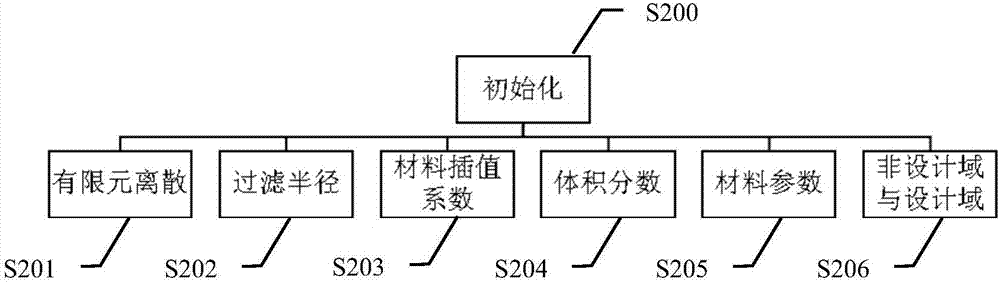

[0212] refer to figure 2 , determine the structural design process of the power battery pack, starting from step S200:

[0213] Step S201: the number of discrete units in the x-axis direction and the y-axis direction of the flat plate with a size of 18cm×18cm is 90;

[0214] Step S202: the filtering radius is set to 2.1;

[0215] Step S203: t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com