NANMAC-E12-3-K-U thermocouple measurement clamp based on thermal-mechanical coupling during milling

A thermo-mechanical coupling, measuring fixture technology, used in measuring/indicating equipment, clamping, manufacturing tools, etc., can solve the problem of inability to measure force and temperature data at the same time, and achieve the effect of flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

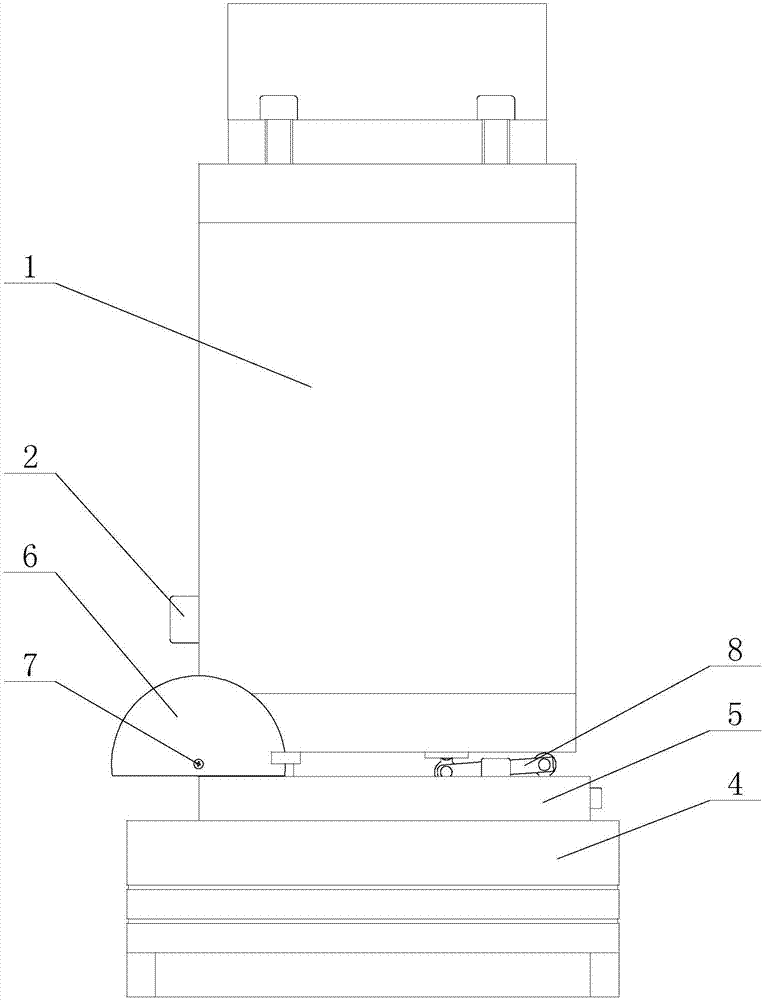

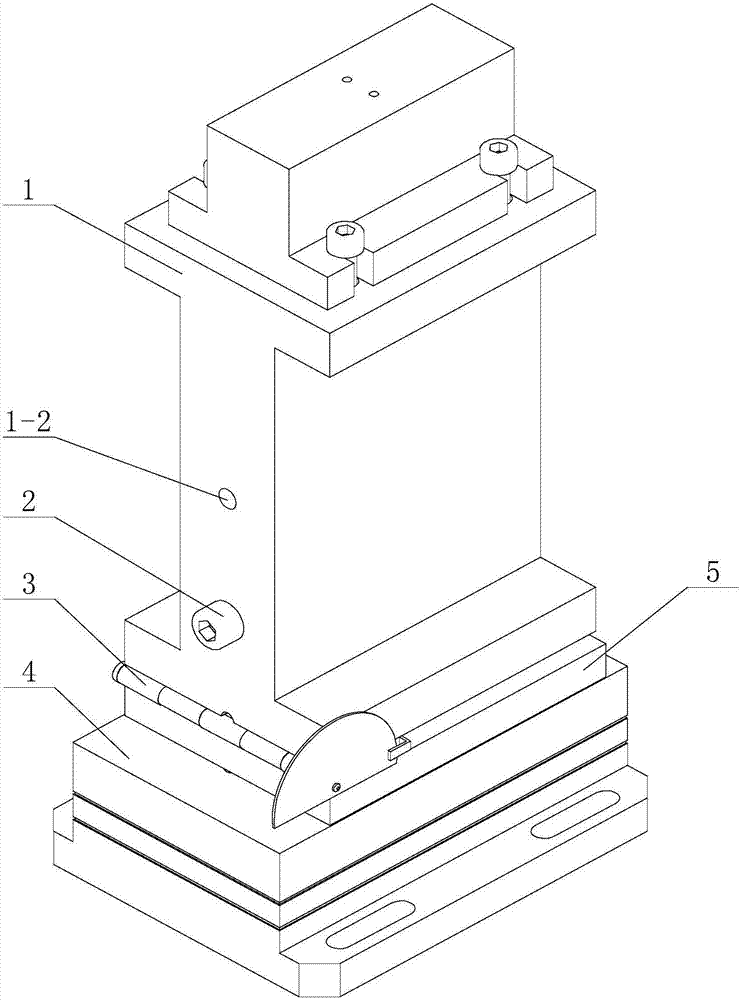

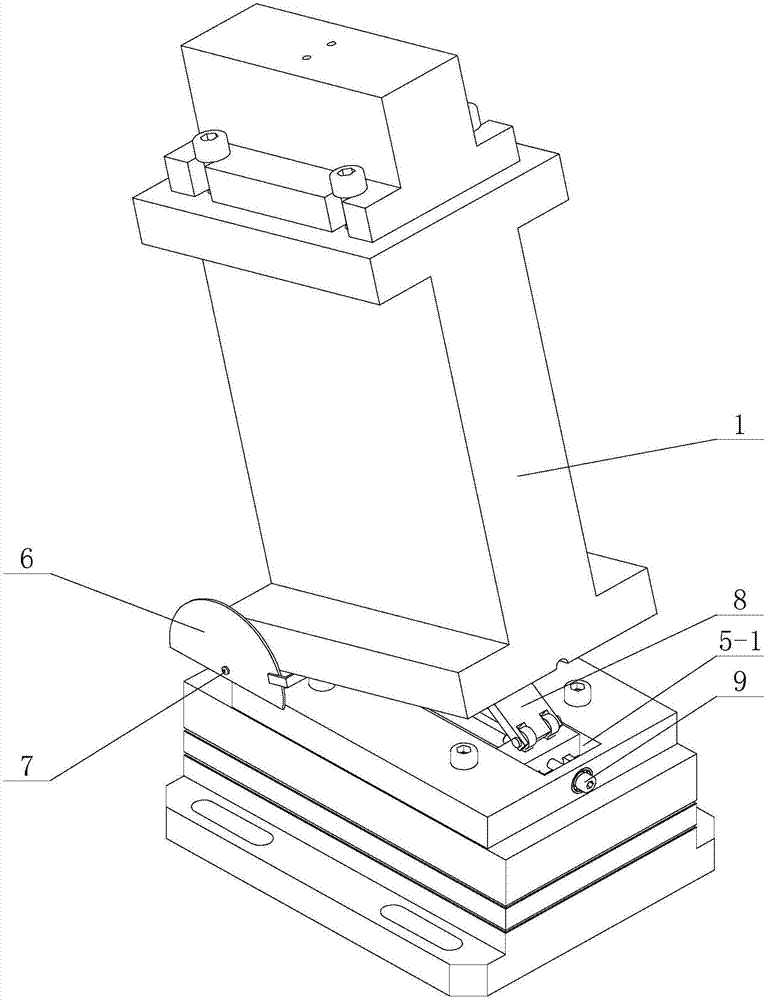

[0010] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment, a NANMAC-E12-3-K-U thermocouple measurement fixture based on thermomechanical coupling during milling described in this embodiment includes a clamp body 1, fixing bolts 2, hinge 3, dynamometer 4, base 5, The support seat assembly and the thermocouple 10, the base 5 are installed on the force measuring instrument 4, one end of the lower surface of the clamp body 1 is rotationally connected with one end of the upper surface of the base 5 through the hinge 3, and the other end of the lower surface of the clamp body 1 passes through the The support seat assembly is connected to the upper surface of the base 5; the clamp body 1 is provided with a cavity 1-1, and the thermocouple 10 is installed in the cavity 1-1 through the fixing bolt 2. In this embodiment, the thermocouple 10 is a NANMAC-E12-3-K-U thermocouple.

specific Embodiment approach 2

[0011] Specific implementation mode two: combination Figure 1 to Figure 4 Describe this embodiment, the NANMAC-E12-3-K-U thermocouple measurement fixture based on thermal coupling during milling described in this embodiment, is characterized in that: the support seat assembly includes a support seat 8 and an adjustment bolt 9, a base 5 The upper surface of the upper surface is provided with a groove 5-1, the support seat 8 is arranged in the groove 5-1, the upper end of the support seat 8 is connected with the lower surface of the clamp body 1, and the lower end of the support seat 8 is arranged in the groove 5-1 , and the lower end of the support seat 8 moves linearly along the groove 5-1, and the adjustment bolt 9 passes through the outer wall of the groove 5-1 to connect with the lower end of the support seat 8. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0012] Specific implementation mode three: combination Figure 1 to Figure 4 Describe this embodiment, the NANMAC-E12-3-K-U thermocouple measurement fixture based on thermal coupling during milling described in this embodiment also includes a dial 6 and a fixing screw 7, and the dial 6 is installed on the hinge through the fixing screw 7 3 on the axis of rotation. The included angle between the clamp body 1 and the horizontal plane can be directly read through the dial 6 . Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com