1400°C high temperature thermal-mechanical coupling test device for the airfoil structure of hypersonic aircraft

A hypersonic, structural testing technology, applied in the testing of machines/structural components, measuring devices, instruments, etc., can solve problems such as deformation, high temperature softening, etc., to achieve the effect of convenient use, safe and reliable connection and use, and simple structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

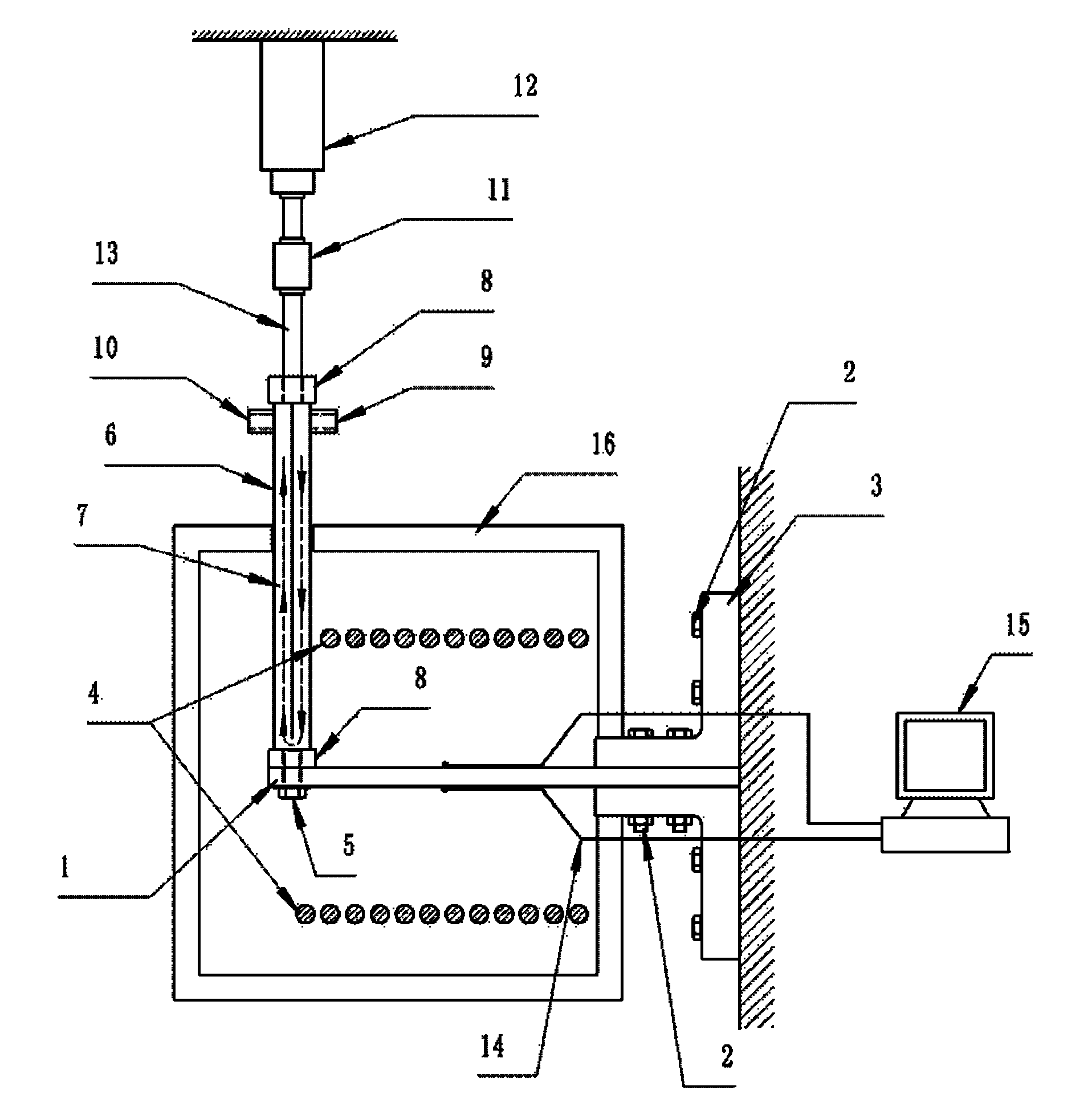

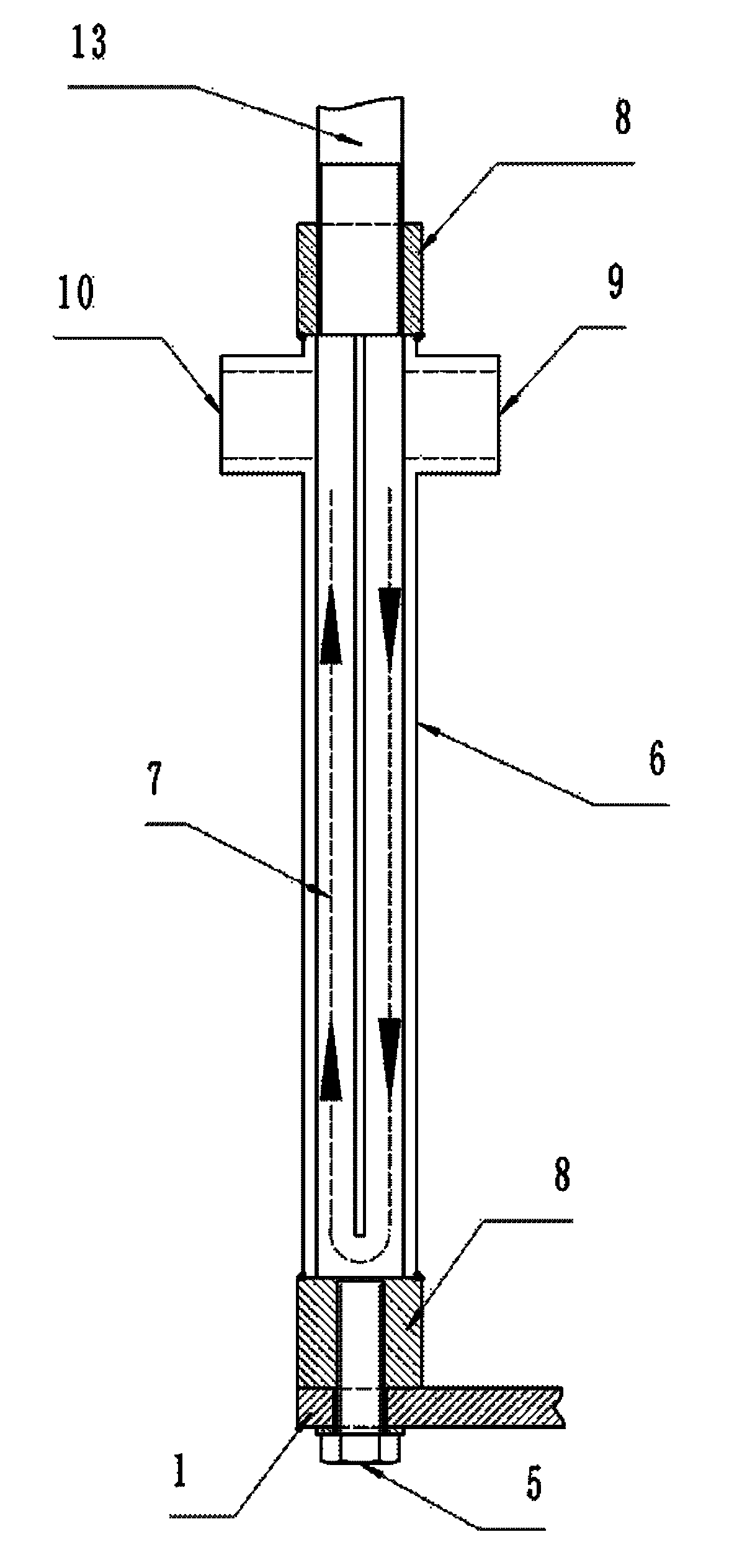

[0017] Such as figure 1 As shown, the present invention consists of a hypersonic vehicle airfoil structure test piece 1, fastening bolts 2, L-shaped fixed support 3, silicon-molybdenum heating array 4, high-temperature fastening bolts 5, water-cooled metal loading assembly 6, U-shaped water-cooled Channel 7, connecting support 8, water inlet 9, water outlet 10, force sensor 11, hydraulic actuator 12, loading coupling rod 13, temperature sensor 14, computer 15 and heat insulation baffle 16.

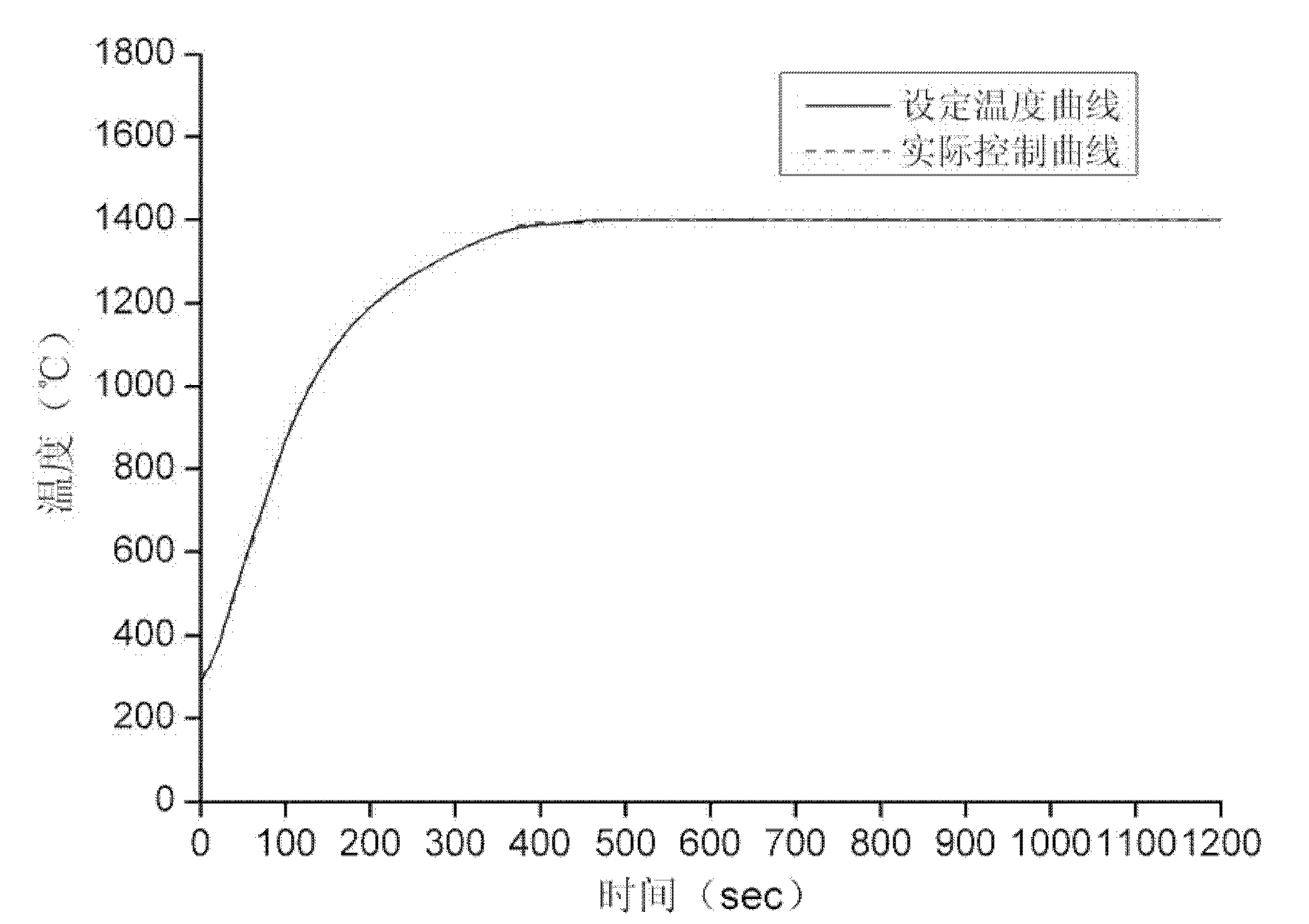

[0018] The hypersonic vehicle airfoil structure test piece 1 is fixed on the L-shaped fixed support 3 by fastening bolts 2 to form a cantilever structure. A row of infrared radiation silicon-molybdenum heating arrays 4 capable of generating a high temperature environment of 1400°C is arranged at a distance of about 50 mm from the upper and lower surfaces of the hypersonic aircraft wing structure test piece 1, to provide the upper and lower surfaces of the hypersonic aircraft wing structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com