Prediction method for turning temperature rise mean value of tool

A prediction method and turning technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of not considering the influence of turning vibration and turning temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

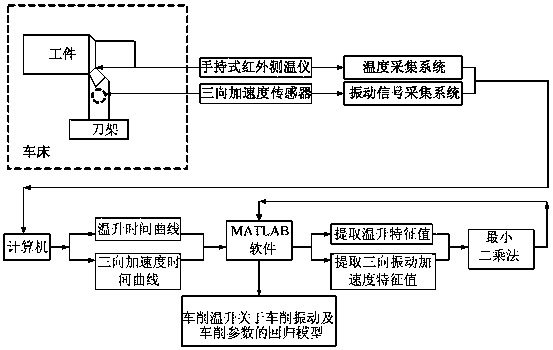

[0069] The present invention will be further explained in conjunction with the drawings.

[0070] Select the turning tool under normal use, and carry out the turning test according to the test plan in Table 1. The amount of each back tool is a p Carry out 12 tests, a total of 36 turning tests, each test time is set to 1 minute.

[0071] Table 1: Test turning parameters

[0072]

[0073] Such as figure 1 As mentioned, a test system for collecting turning temperature signals and tool three-way vibration signals is established.

[0074] The temperature collection system collects the temperature at the tip of the rake face of the tool through the OS523E-2 infrared thermometer produced by the American OMEGA company.

[0075] The vibration signal acquisition system collects the three-directional vibration signal at the lower surface of the tool holder corresponding to the tip of the tool rake face through the piezoelectric three-directional acceleration sensor, and the three-directional vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com