Steel structure welding deformation analytical method

A welding deformation and analysis method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of accidental product quality, heavy repair process workload, waste of fuel costs, etc., and achieve a simple welding production process , Reduce the effect of handling trimming procedures, reducing man-hour costs and fuel costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in detail below with reference to accompanying drawing and embodiment:

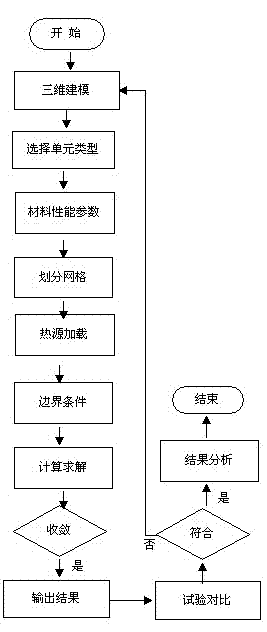

[0037] attached figure 2 It can be seen that a method for analyzing deformation of steel structure welding in the present invention comprises the following steps:

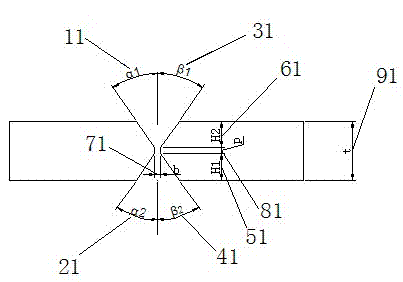

[0038] a. Establish a computer welded joint model to simplify five standard joints: flat V-shaped butt joint, flat X-shaped butt joint, T-shaped joint V-shaped groove, T-shaped joint X-shaped groove, and corner joint V-shaped groove There are two forms of plate butt joint and T-joint;

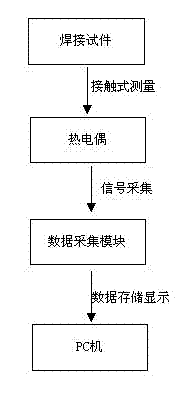

[0039] b. On-site data collection;

[0040] c. Computer thermal-mechanical coupled finite element simulation;

[0041] d. Data comparison, the data obtained through the experiment and the data analyzed by the three-dimensional model are compared and checked;

[0042] e. Formulate the welding process; calculate the welding residual deformation and stress of the joint by inputting welding methods, groove parameters, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com