Testing method and device for influence relation of thermal contact resistance of bonding surface by normal load

A technology of contact thermal resistance and measuring device, which is applied in the direction of material thermal development, etc., can solve the problems of unsuitable equipment and affect the contact thermal resistance of the contact surface, etc., and achieve the effect of convenient production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

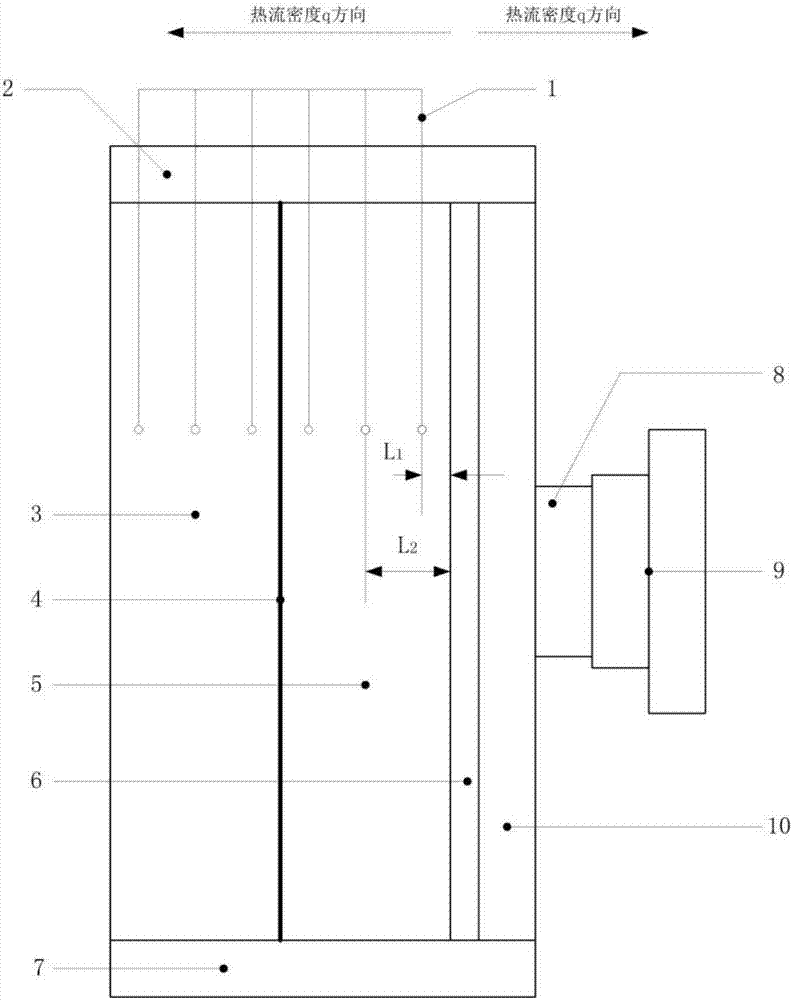

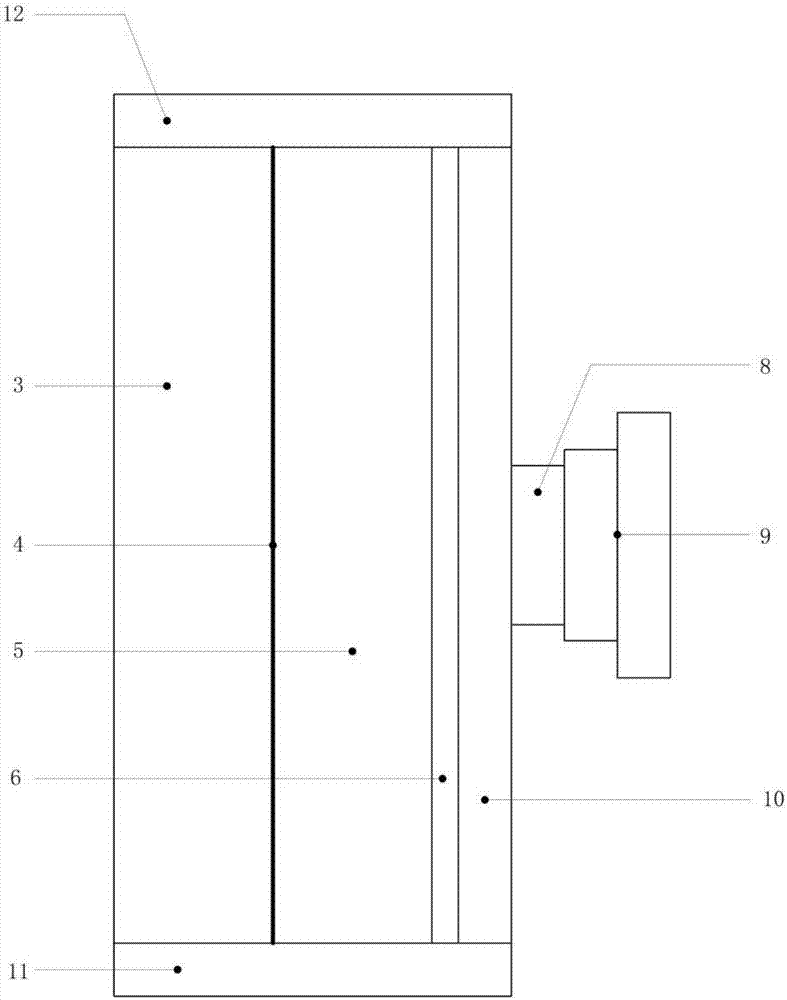

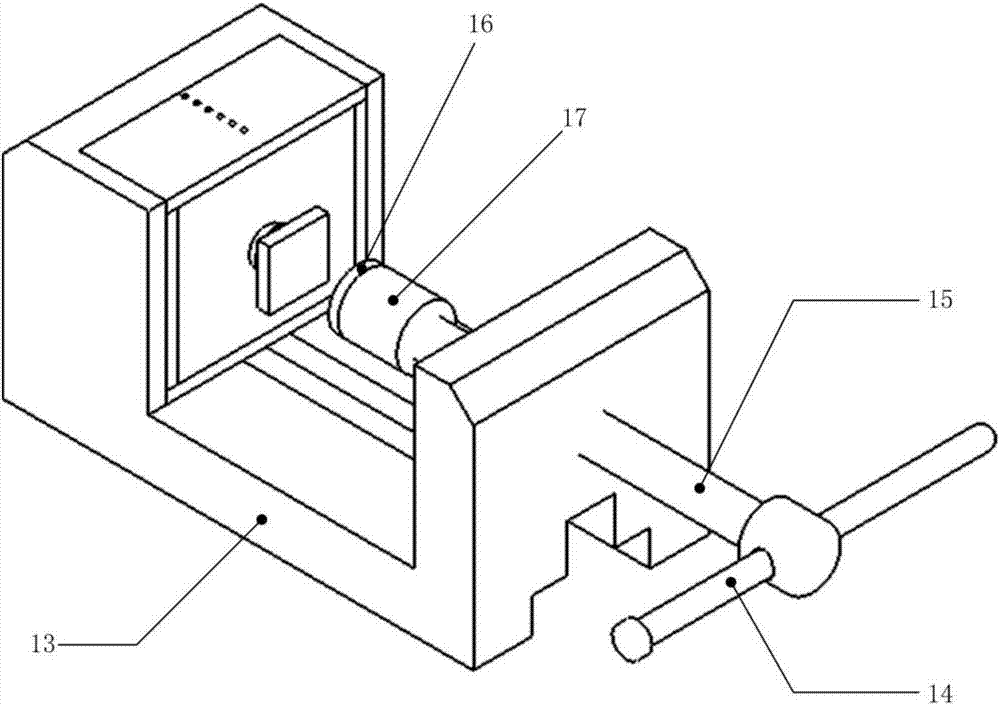

[0020] The first step, preparation of test specimens and equipment

[0021] Take two pieces to be tested (specification 150×130×30), that is, the outer test piece 3 and the inner test piece 5, and place them side by side; in addition, place the heating device 6 (specification 150×130×4) closely with the inner test piece 5 Bonding; then the sensor fixing device 10 (specification 150 × 130 × 10) is closely attached to the other side of the heating device 6, the sensor fixing device 10 has the function of fixing the pressure sensor 8, and also has the function of making the heating device 6 The effect of the heat generated is evenly transmitted from left to right; the sensor block 9 is installed on the pressure sensor 8, its purpose is to protect the pressure sensor 8, in addition to making the applied force more uniform on the sensor; in the device The upper, lower, front and rear are respectively provided with upper heat insulation device 2 (specification 170×74×10), lower heat...

Embodiment 2

[0038] The difference from Example 1 is that the two test pieces are made of different materials from the first two test pieces in the embodiment, and the other conditions are kept the same. Through the above steps, the contact thermal resistance and normal direction of the joint surface of the two test pieces of different materials are obtained. load relationship.

Embodiment 3

[0040] The difference from Example 1 is that the surface roughness value Ra of the two test pieces is changed, and other conditions remain unchanged. Through the above steps, the contact heat of the joint surface of the two test pieces is obtained under different surface roughness Ra conditions. The relationship between resistance and normal load.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com