Automatic conveying and cutting device for building wood board

An automatic feeding and cutting device technology, which is applied to wood processing appliances, forming/shaping machines, manufacturing tools, etc., can solve the problem of sawdust falling in the eyes of the staff, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

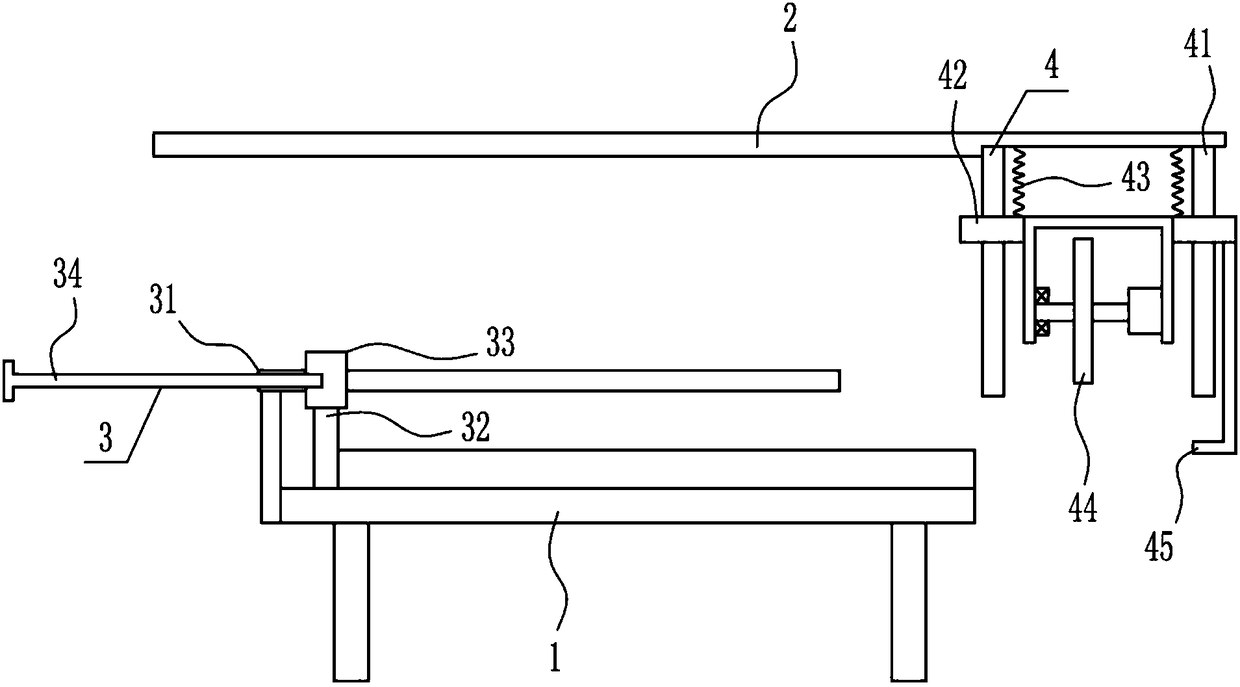

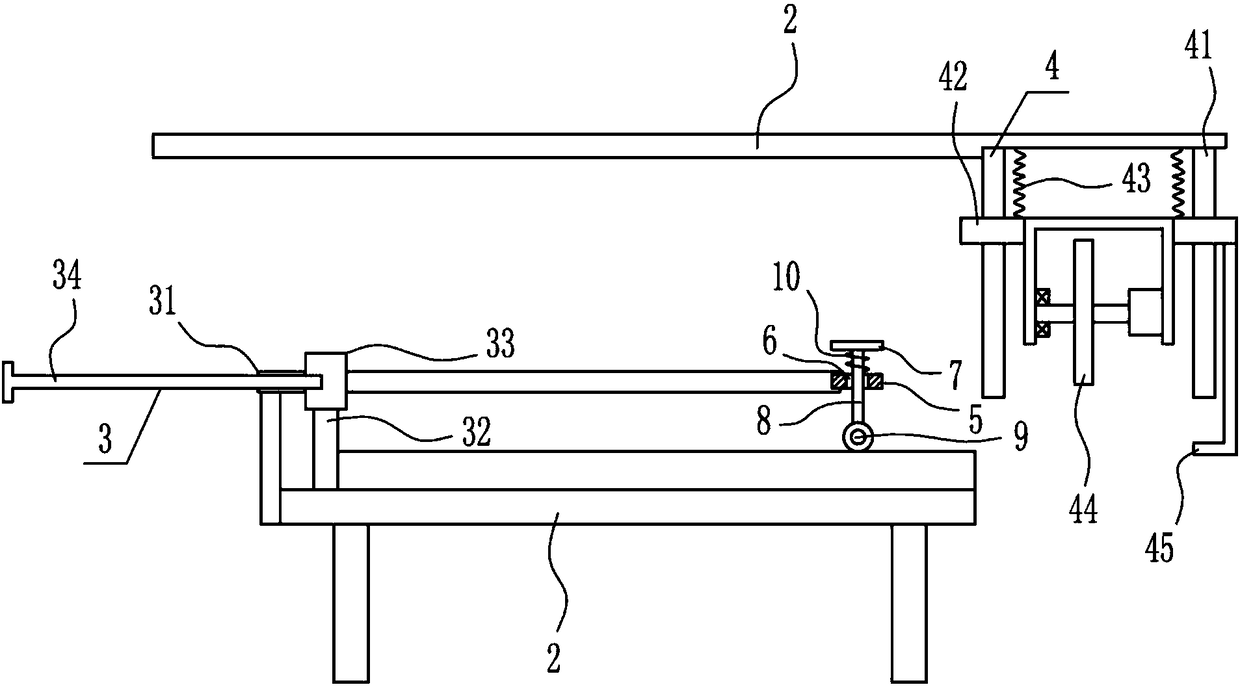

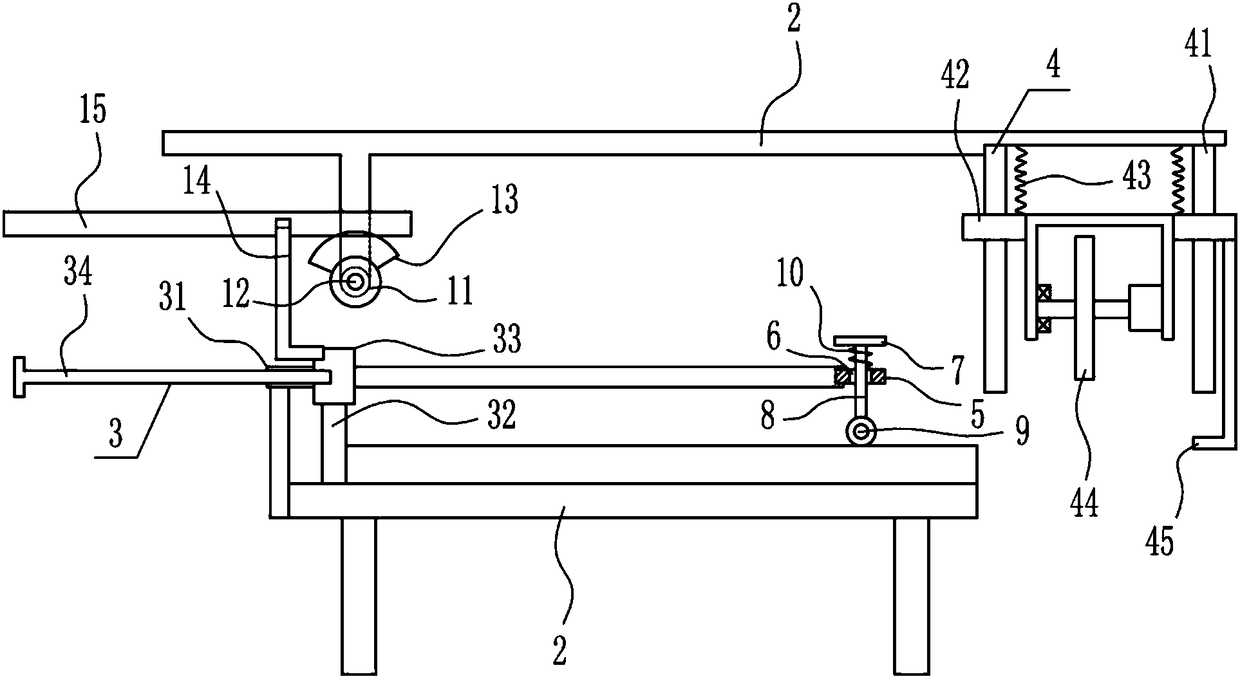

[0029] An automatic feeding and cutting device for building material planks, such as Figure 1-4 As shown, it includes a workbench 1, a top plate 2, a moving mechanism 3 and a cutting mechanism 4, the top of the workbench 1 is connected with the moving mechanism 3, the top of the workbench 1 is provided with a top plate 2, and the right side of the top plate 2 is connected with a cutting mechanism 4.

Embodiment 2

[0031] An automatic feeding and cutting device for building material planks, such as Figure 1-4 As shown, it includes a workbench 1, a top plate 2, a moving mechanism 3 and a cutting mechanism 4, the top of the workbench 1 is connected with the moving mechanism 3, the top of the workbench 1 is provided with a top plate 2, and the right side of the top plate 2 is connected with a cutting mechanism 4.

[0032] The moving mechanism 3 includes a first guide rail 31, a push plate 32, a first guide sleeve 33 and a push rod 34. The top of the workbench 1 is connected with the first guide rail 31, and the first guide rail 31 is slidably connected with the first guide sleeve 33. A push plate 32 is connected to the bottom of the first guide sleeve 33 , and the bottom of the push plate 32 contacts the workbench 1 .

Embodiment 3

[0034] An automatic feeding and cutting device for building material planks, such as Figure 1-4 As shown, it includes a workbench 1, a top plate 2, a moving mechanism 3 and a cutting mechanism 4, the top of the workbench 1 is connected with the moving mechanism 3, the top of the workbench 1 is provided with a top plate 2, and the right side of the top plate 2 is connected with a cutting mechanism 4.

[0035] The moving mechanism 3 includes a first guide rail 31, a push plate 32, a first guide sleeve 33 and a push rod 34. The top of the workbench 1 is connected with the first guide rail 31, and the first guide rail 31 is slidably connected with the first guide sleeve 33. A push plate 32 is connected to the bottom of the first guide sleeve 33 , and the bottom of the push plate 32 contacts the workbench 1 .

[0036] The cutting mechanism 4 includes a second guide rail 41, a second guide sleeve 42, a first spring 43, an electric saw wheel 44 and a pull bar 45, the right side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com