High-efficiency punching device suitable for furniture board

A drilling device and drilling device technology, applied in drilling accessories, manufacturing tools, wood processing equipment, etc., can solve problems affecting efficiency, inconvenience, manual replacement of drill bits, etc., to improve work efficiency, improve cleanliness, improve The effect of the drilling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

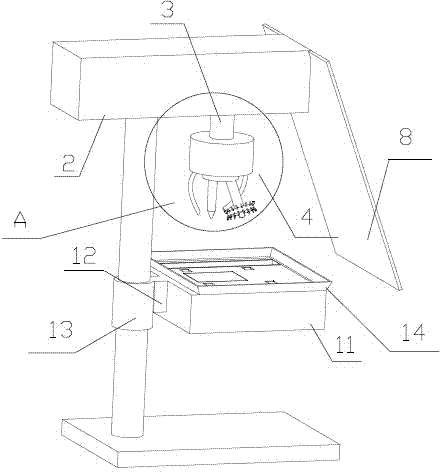

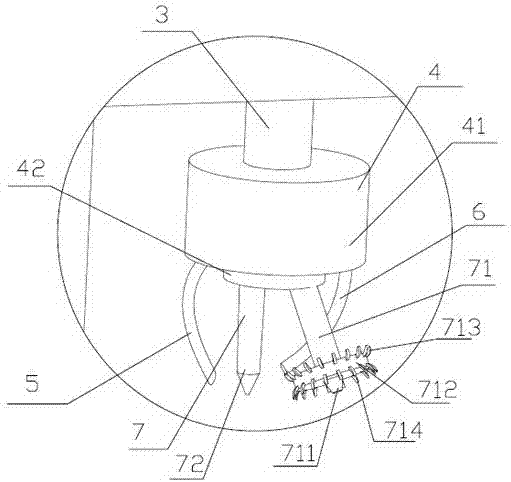

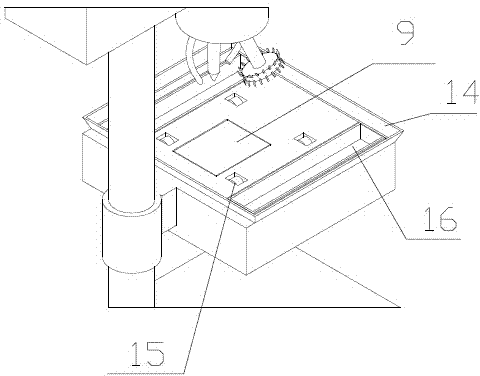

[0031] Example 1, such as figure 1 figure 2 and image 3 Shown: a high-efficiency punching device suitable for furniture panels, including a frame 2 and a drilling device 4 for punching furniture panels, this kind of high-efficiency punching device for furniture panels also includes a connection with the frame 2 and An operating table 1 for holding furniture panels that can move vertically on the frame 2, one end is connected to the frame 2 and the other end is connected to the drilling device 4, and the drilling device 4 can be adjusted relative to the frame. 2 The vertical distance lifting device 3, the oil spraying device 6 for spraying machine oil at the drilling position and the cleaning device 5 for cleaning the drilling position with water spray; The sliding collar 13, the connector 12 connecting the console 1 and the collar 13, the operating surface 11 is also provided with a conveying device 15 for transferring furniture panels to adjust the punching position; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com