Wood fixed-dimension high-precision cutting and waste recycling integrated equipment

A technology of waste recycling and sizing, which is applied to sawing equipment, wood processing equipment, sawing components, etc., and can solve the problems of physical injury of workers and heavy labor of manual cutting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

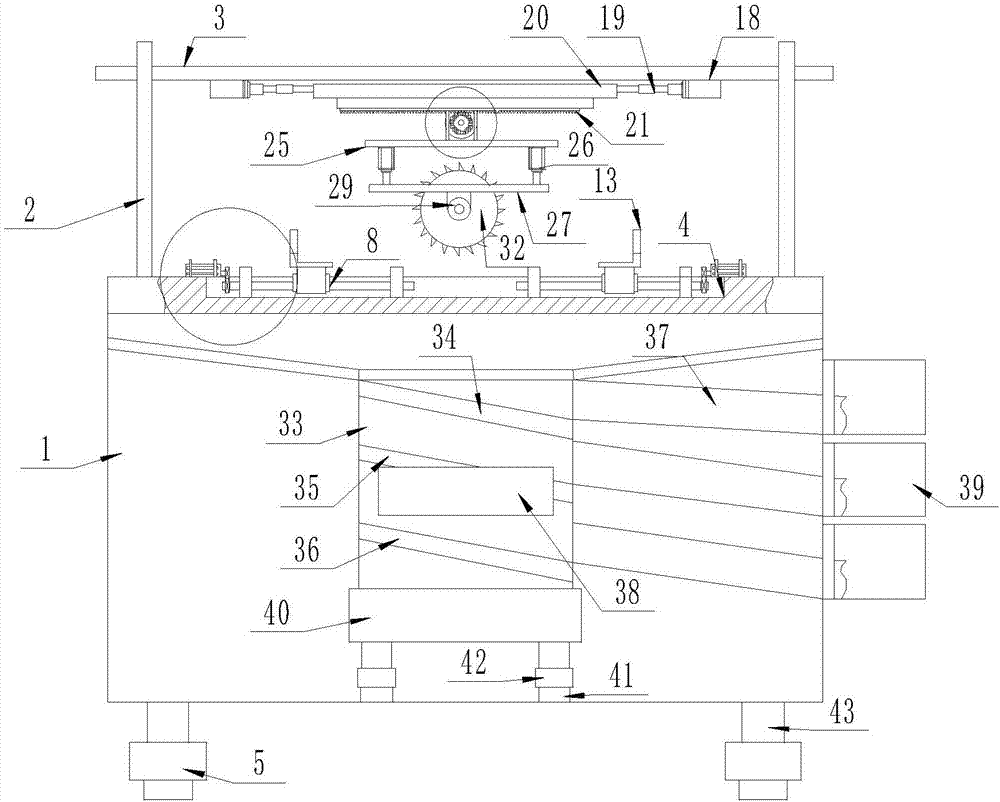

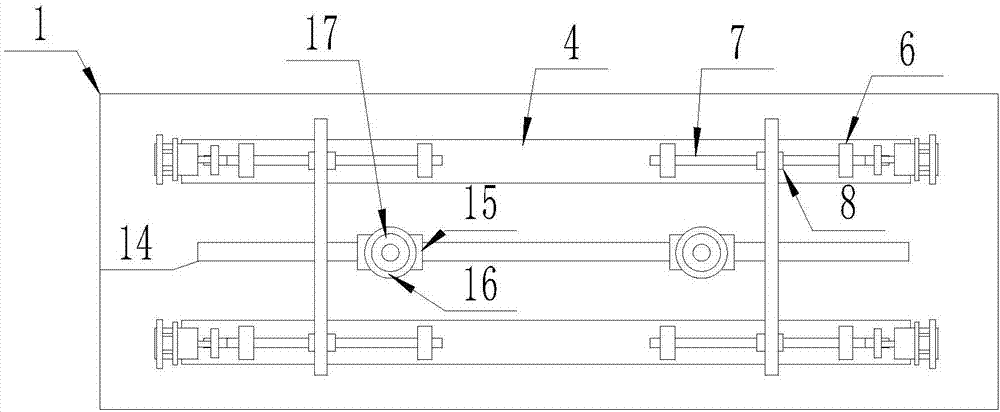

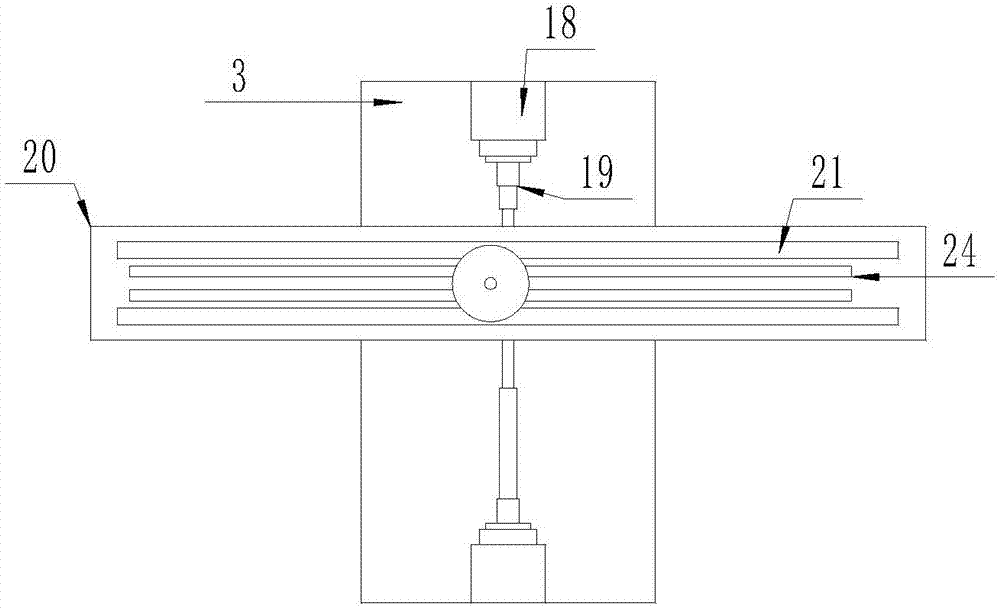

[0024] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-6 As shown, an integrated equipment for sizing and high-precision cutting of wood and recycling waste materials includes a base 1, the inside of which is a hollow structure; and the outside is a rectangular mechanism, and the upper surface of the base 1 is provided with a plate feeding mechanism. The plate feed mechanism is provided with a clamping mechanism, a pair of guide rods 2 are fixed on the base 1, and a beam 3 is fixed on the guide rod 2, and a transverse feed mechanism is provided on the beam 3. The feeding mechanism is provided with a longitudinal feeding mechanism, the longitudinal feeding mechanism is provided with a lifting mechanism, the lifting mechanism is provided with a cutting mechanism, the base 1 is provided with a waste recovery mechanism, and the plate feeding mechanism It is fixed in the chute 4 by the chute 4 horizontally opened on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com