Device used for machining plate side face hole groove

A technology of hole grooves and plates, which is applied to the device for processing plate side hole grooves and the field of plate processing devices, which can solve the problems of insufficient efficiency and precision in positioning processing, low overall efficiency of equipment, and wear and tear of plate conveying, so as to ensure high efficiency and accuracy , to ensure timeliness and smoothness, and to improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

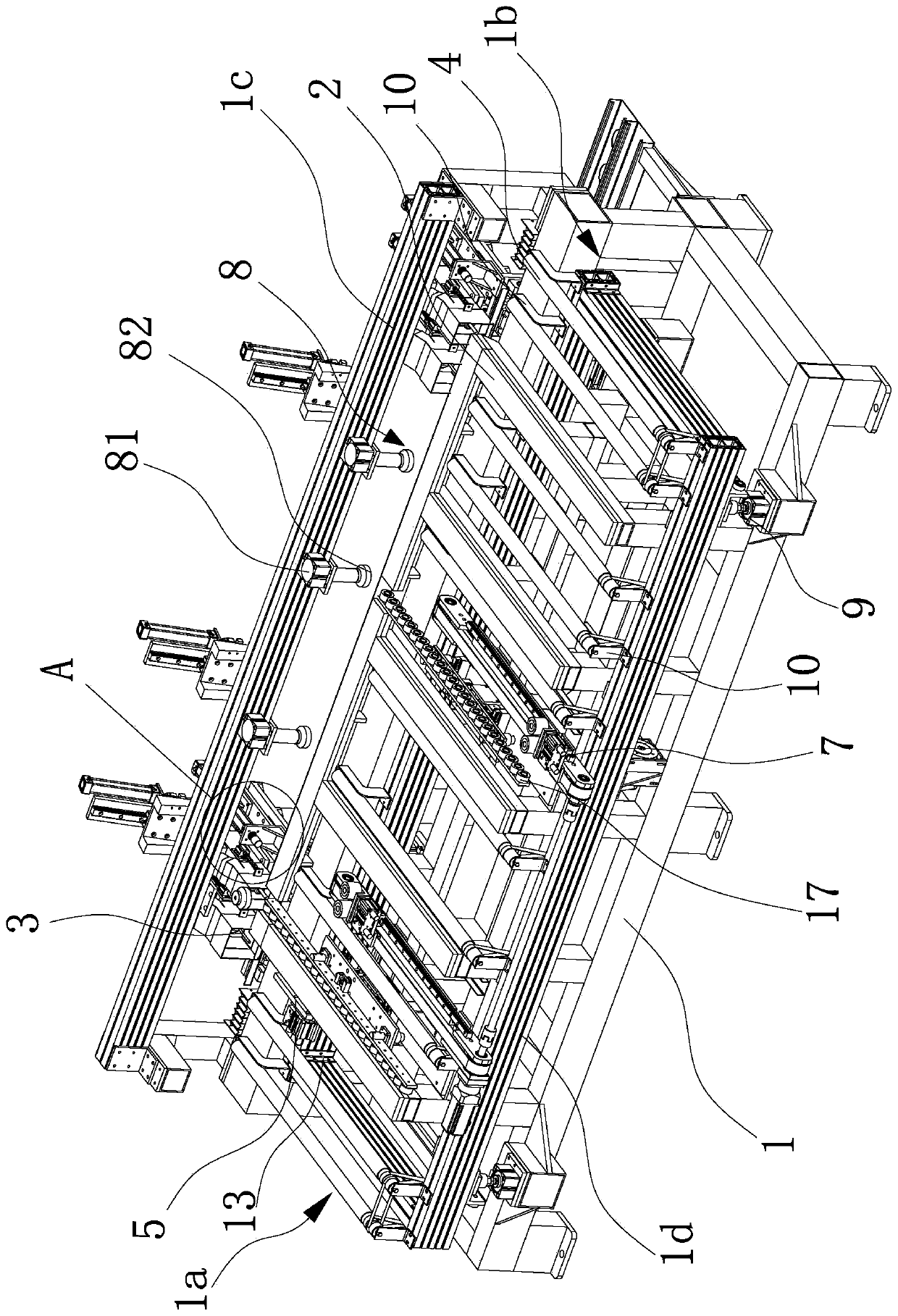

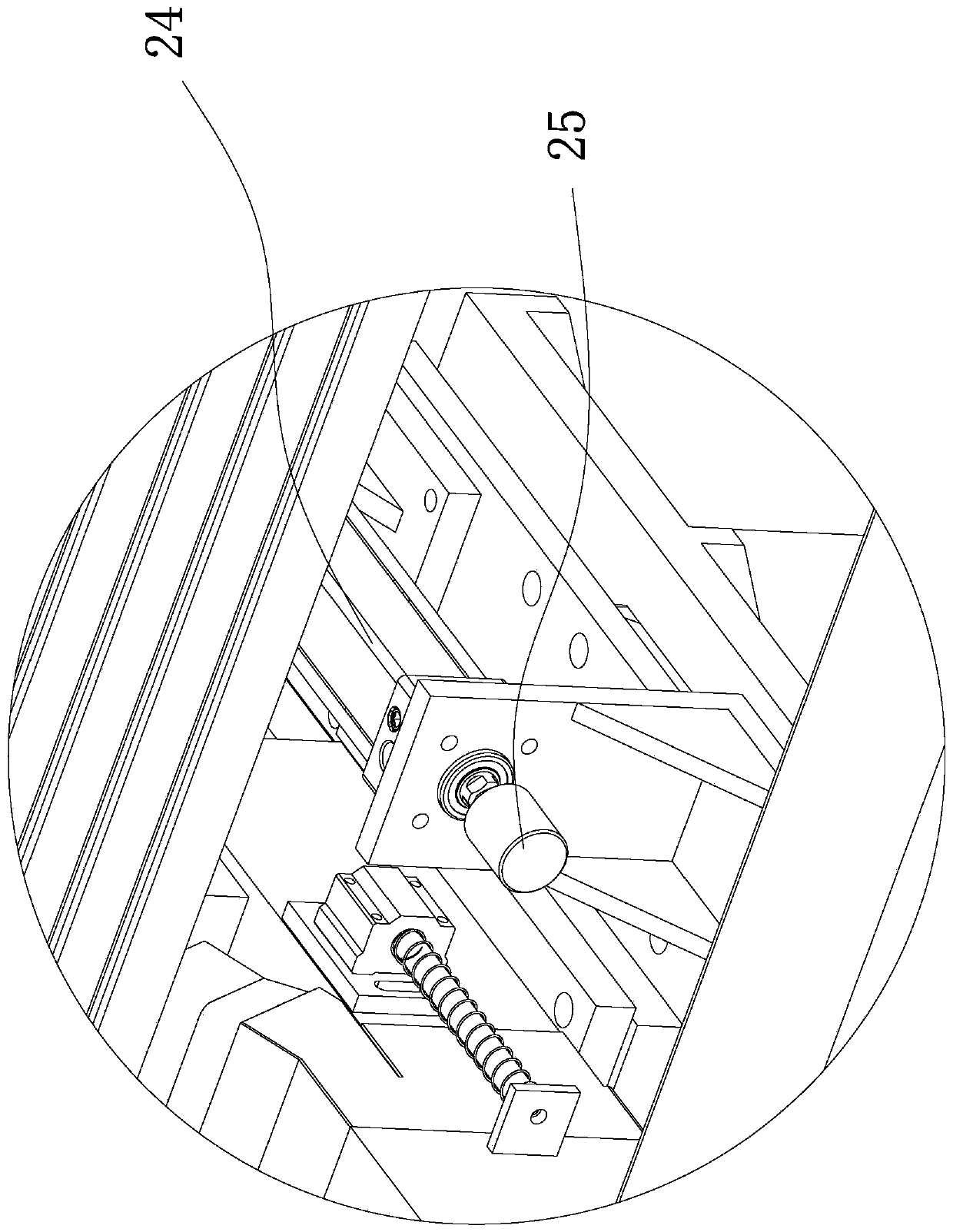

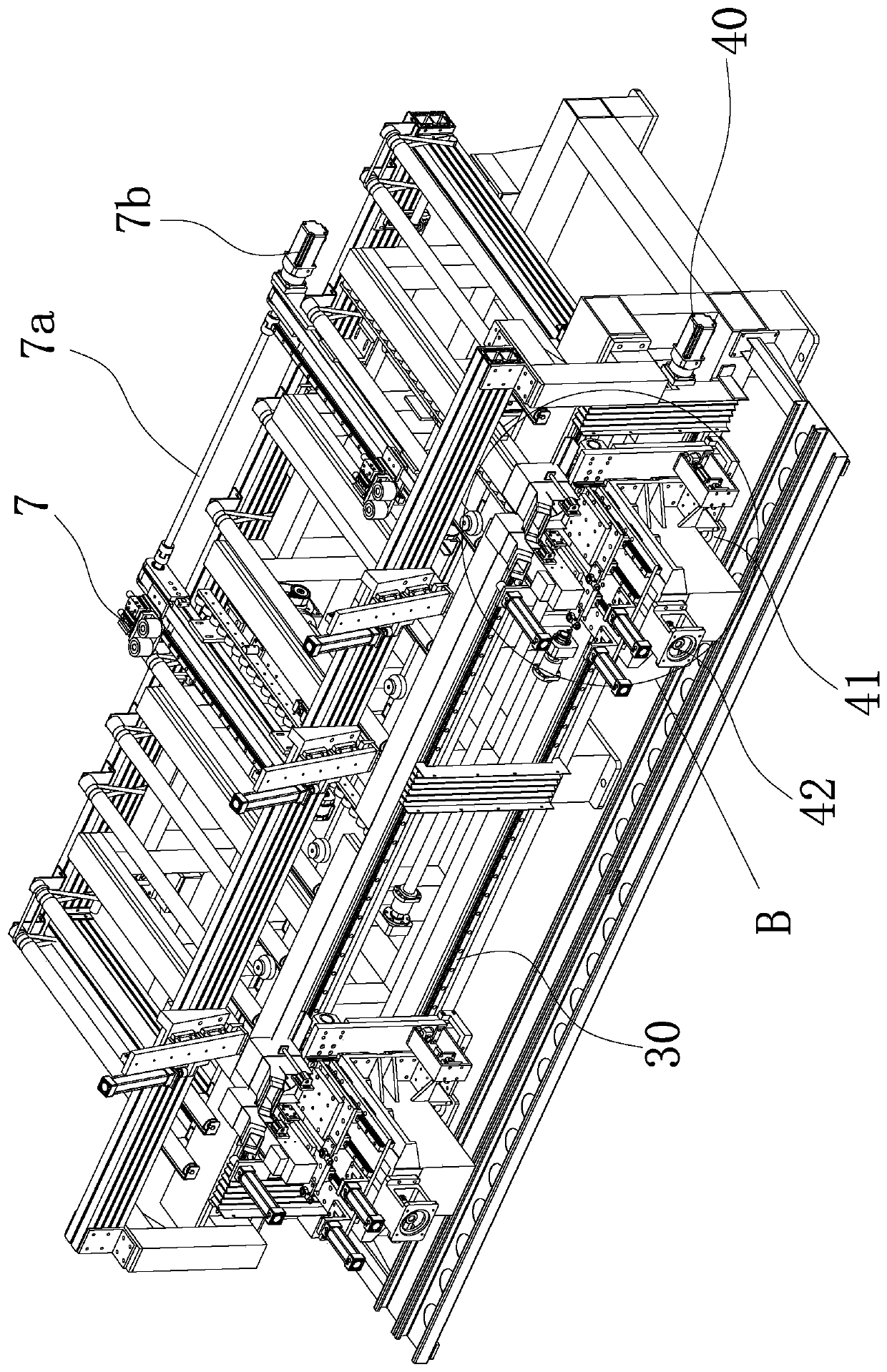

[0039] The device is used for processing mounting holes and mounting grooves on the plate, such as hinge mounting holes, mounting grooves, lock holes, etc.; in this embodiment, the processing of door plate workpieces is taken as an example. like Figure 1 to Figure 5 as well as Figure 9 As shown, the device includes a frame 1, one end of the frame 1 is an input end 1a, and the other end is an output end 1b, a plurality of working platforms 2 are fixed on the frame 1, and at least one set of Facing the working head 3 of the working platform 2, a group of rollers 4 that can be raised and lowered are provided on the frame 1 from the input end 1a to the output end 1b of the frame 1. Between the rollers 4, there is a roller t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com