Sheet Metal Web Stiffener And Chord Nailing Restrictor For Wooden I-Joist

a technology of sheet metal web and restrictor, which is applied in the direction of girders, joists, trusses, etc., can solve the problems of increasing the tendency of splicing, high mechanical strength, and the potential degrading factor of the load carrying capacity of the i-joist, so as to achieve the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

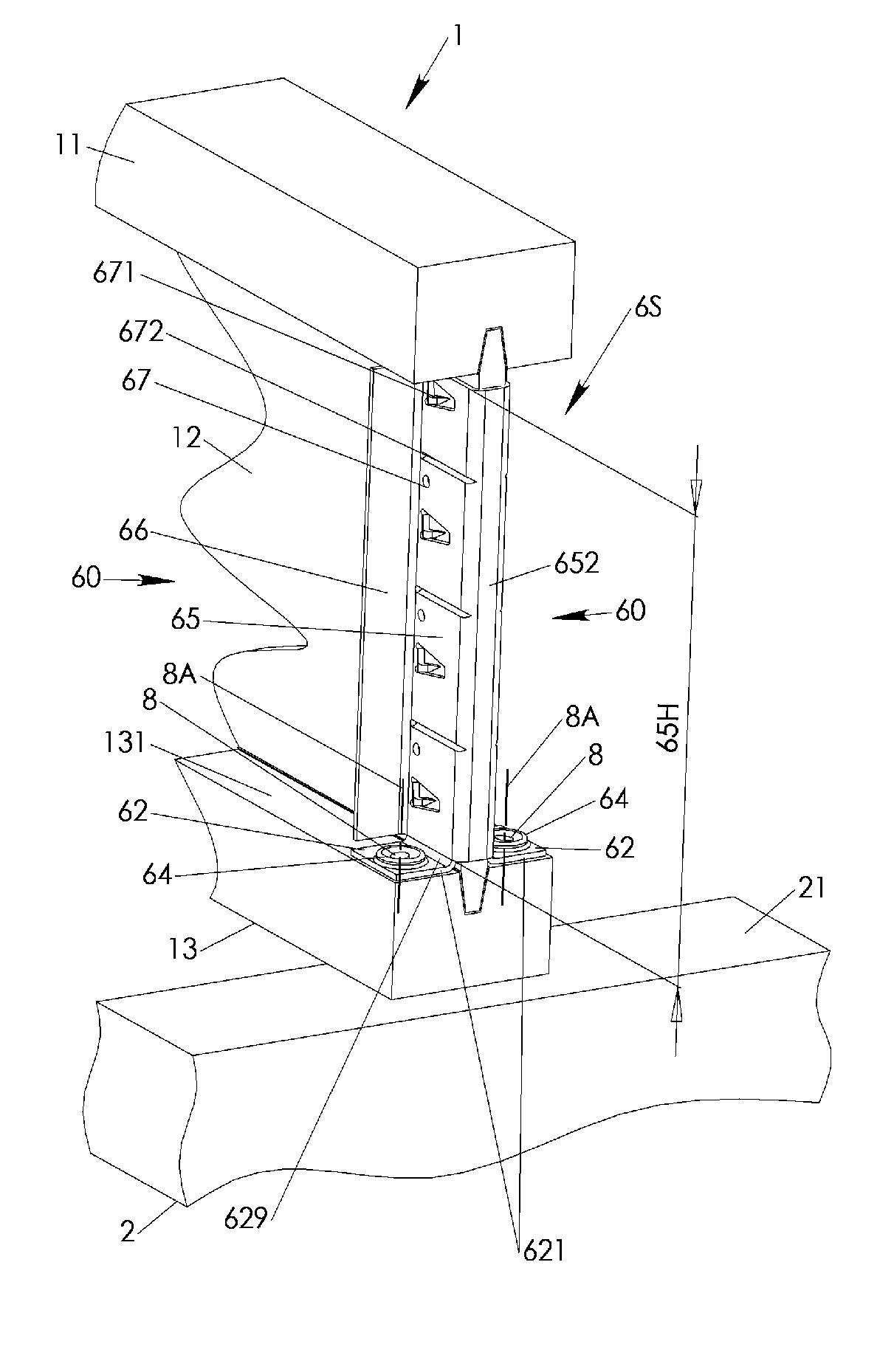

[0028] In the invention depicted in FIGS. 3, 4, AA, BB, 5, a device 6S for restricting nailing on a wooden I-joist 1 may feature a nail restricting hole 63 in a chord plate 62 that has a web edge 629. The nail restricting hole 63 is with its center axis 8A in a web nailing clearance CW to the web edge 629 and in a chord front clearance CF to a I-joist front flush face 621 / 6521. The nail restricting hole 63 may have a restricting diameter 63D such that only a suitable nail 8 having a shaft diameter 8D of up to the restricting diameter 63D may be nailed through the nail restricting hole 63. Web and chord nailing clearances CW, CF as well as restricting diameter 63D may be selected in accordance with well known chord nailing standards established by wooden I-joist 1 manufacturers. The chord plate 62 has a top 627 and bottom 628.

[0029] The I-joist front flush face 621 / 6521 is preferably perpendicular to the web edge 629. In case of an employed web front bridge plate 652 described in mor...

second embodiment

[0037] In the device 6N depicted in FIGS. 6, 7, two chord plates 62 are combined by an I-joist front plate 6222 extending substantially perpendicular away from the bottom side of the chord plates 62. Each of the two chord plates 62 has a chord front edge 6224 substantially collinear to each other and perpendicular to respective web edges 629. The web edges are facing each other substantially parallel spaced apart by web contacting gap 65G. Chord plates 62 and I-joist front plate 6222 may be fabricated from sheet metal, preferably as a monolithic structure. The device 6N operates mainly as nail restricting device. An independent well known web stiffener 5 may be attached after placement of the device 6N.

[0038] In the first and second embodiment device 6S, 6N a centering funnel 64 may be provided by the chord plate 62 surrounding the nail restricting hole 63. In case of the chord plate 62 being made of sheet metal, the centering funnel 64 may be embossed into the chord plate 62 with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com