Heating stage and heating stage device for X-ray microprobes and experimental method of heating stage device

A technology of microprobe and hot stage, which is applied in measuring devices, material analysis using wave/particle radiation, instruments, etc. It can solve the problems of hindering sample backscattered fluorescence detection, difficult sample centering, low X-ray transmittance, etc. problems, to achieve the effect of improving the temperature uniformity of the sample and heating the parts comprehensively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0206] The heat stage, heat stage device and experimental method of the radiation microprobe according to the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments below.

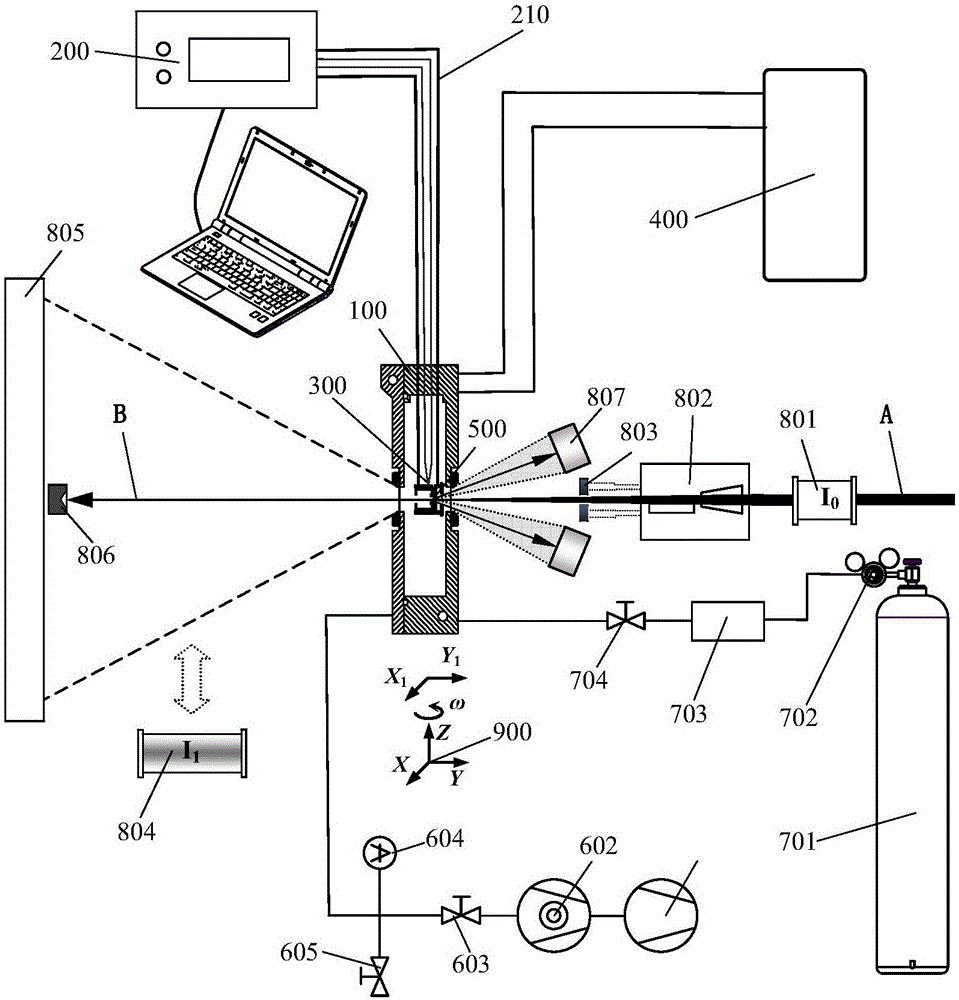

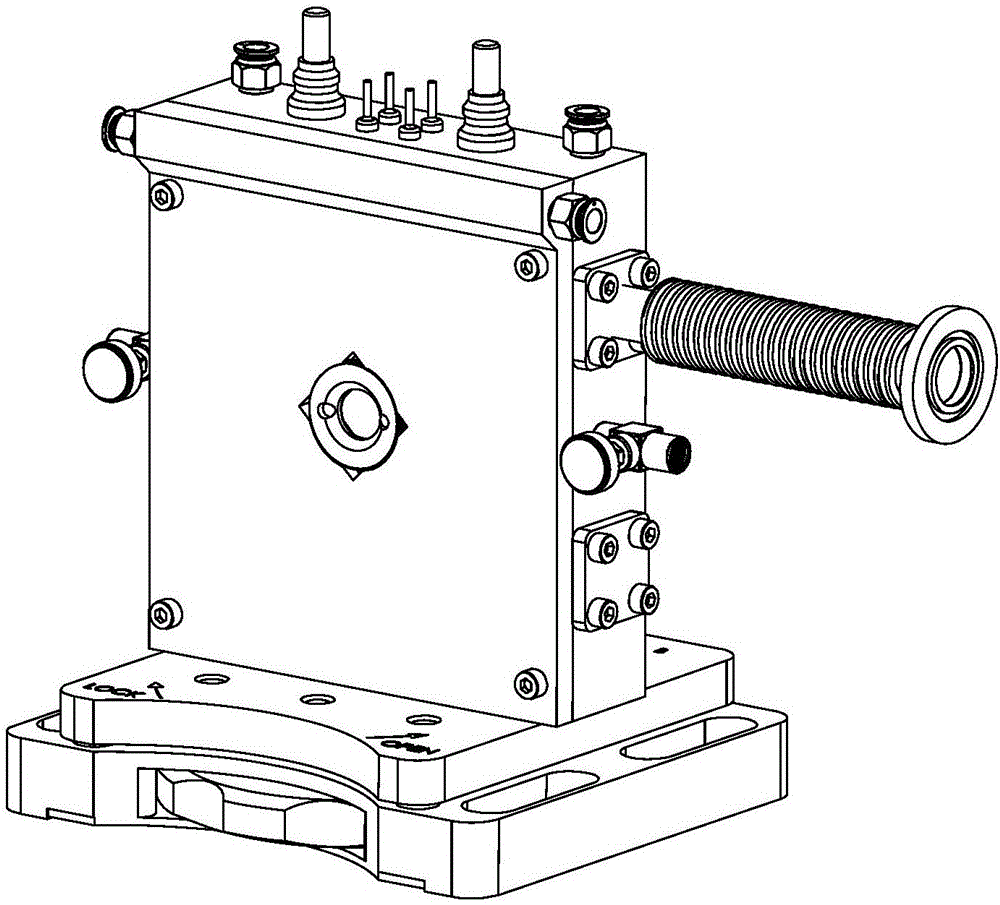

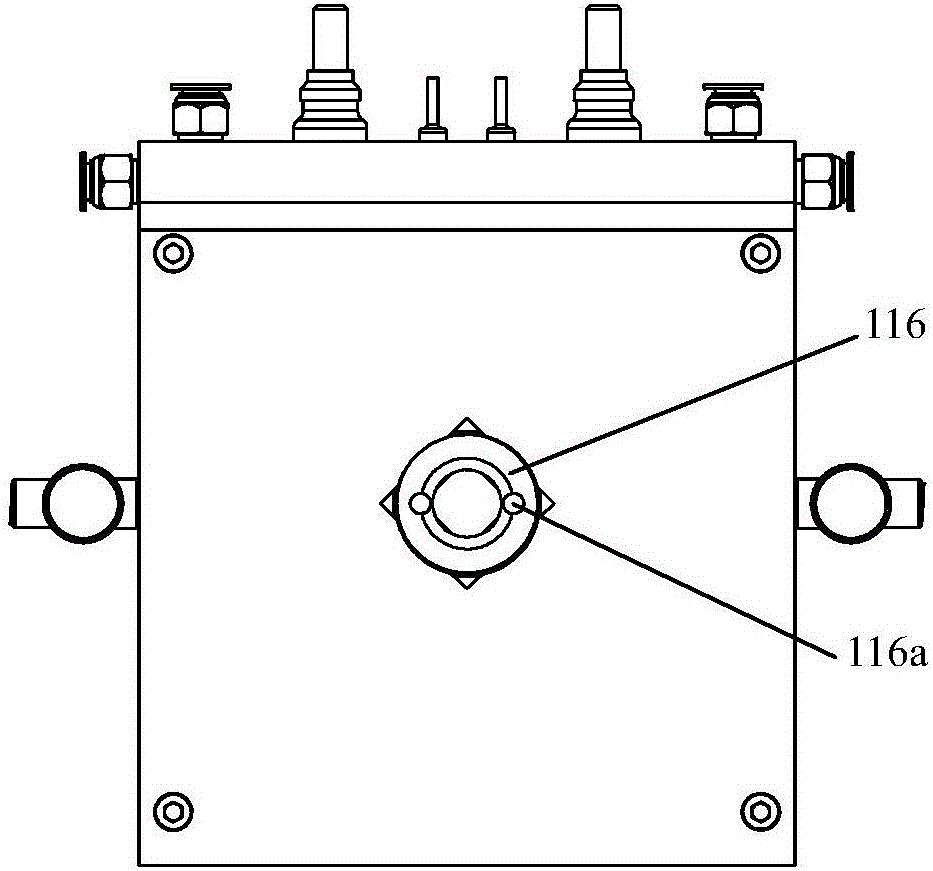

[0207] figure 1 The structure of the heat stage device of the radiation microprobe according to one embodiment of the present invention is shown.

[0208] Such as figure 1 shown, combined with reference figure 2 , the hot stage 100 of the hard X-ray microprobe is set on the motorized six-dimensional (X, Y, Z, ω, X 1 , Y 1 ) on the sample positioning platform 900, which are respectively connected with the temperature controller 200, the circulating water cooler 400, the vacuum pump unit (including the rotary vane vacuum pump 601, the turbomolecular pump 602) and the process / protection gas supply device. Wherein, the process / protection gas supply device includes a gas cylinder 701, a pressure reducing valve 702, a flow meter 703, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com