Triaxial test machine and testing system

A triaxial test and specimen technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

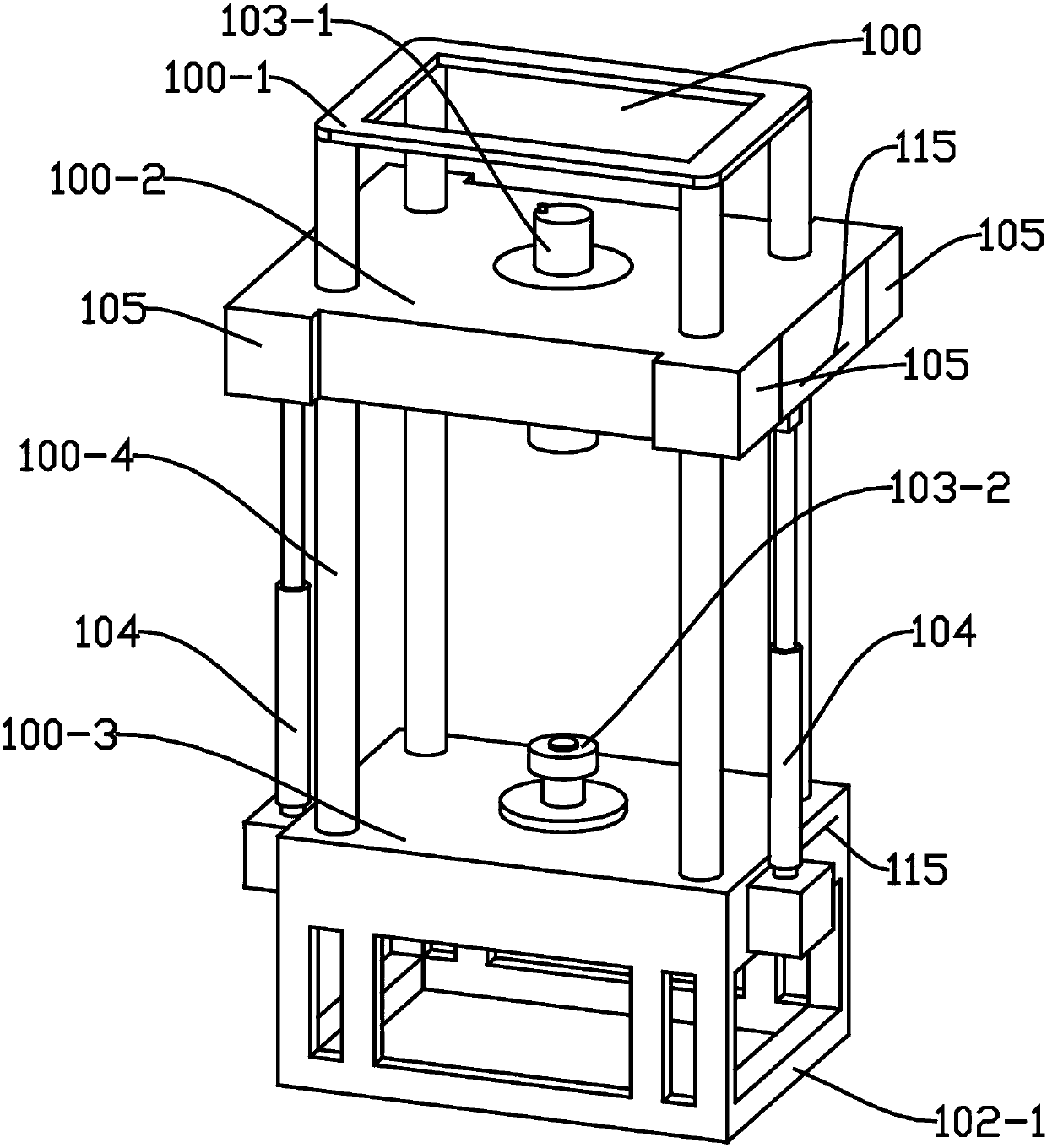

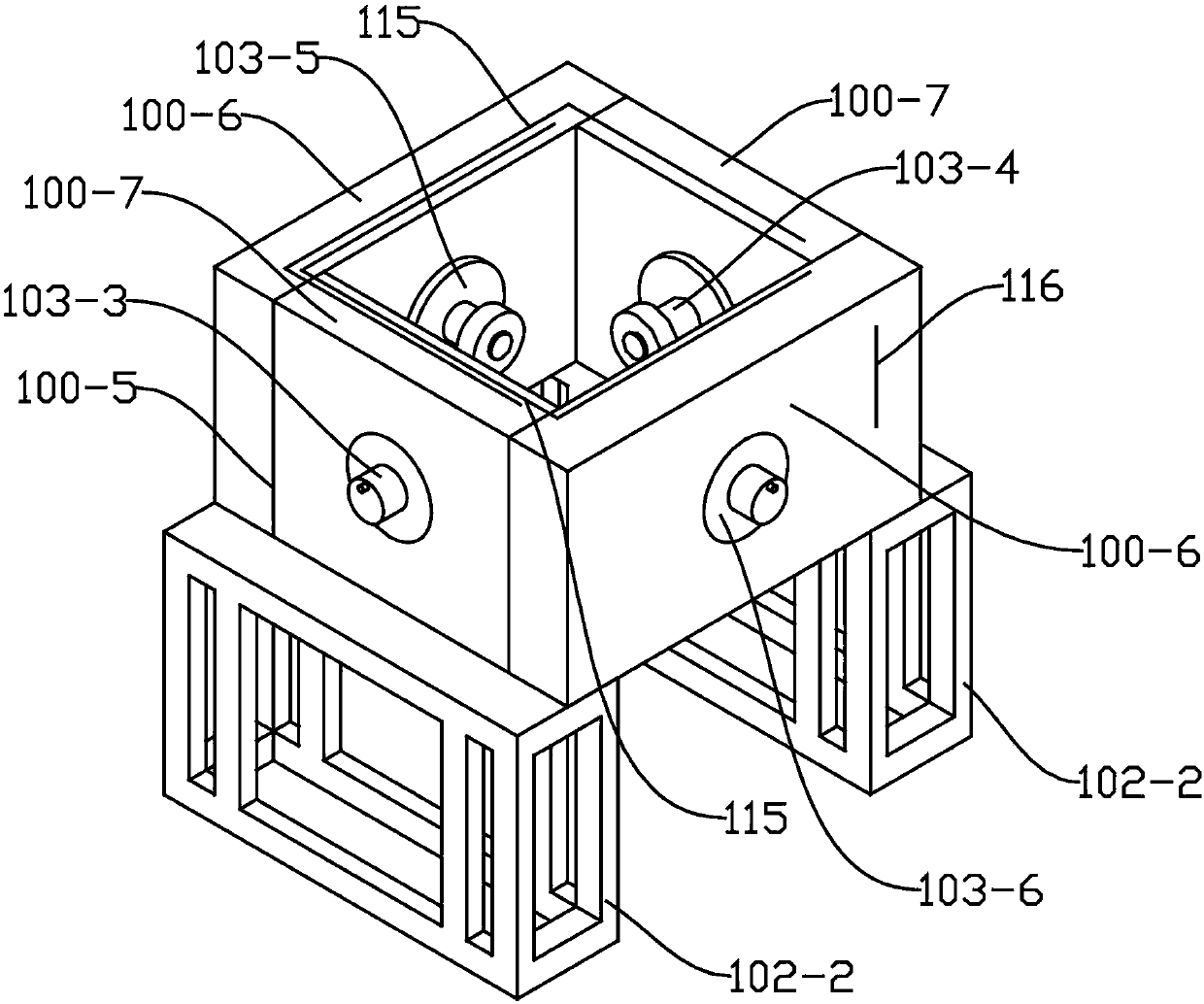

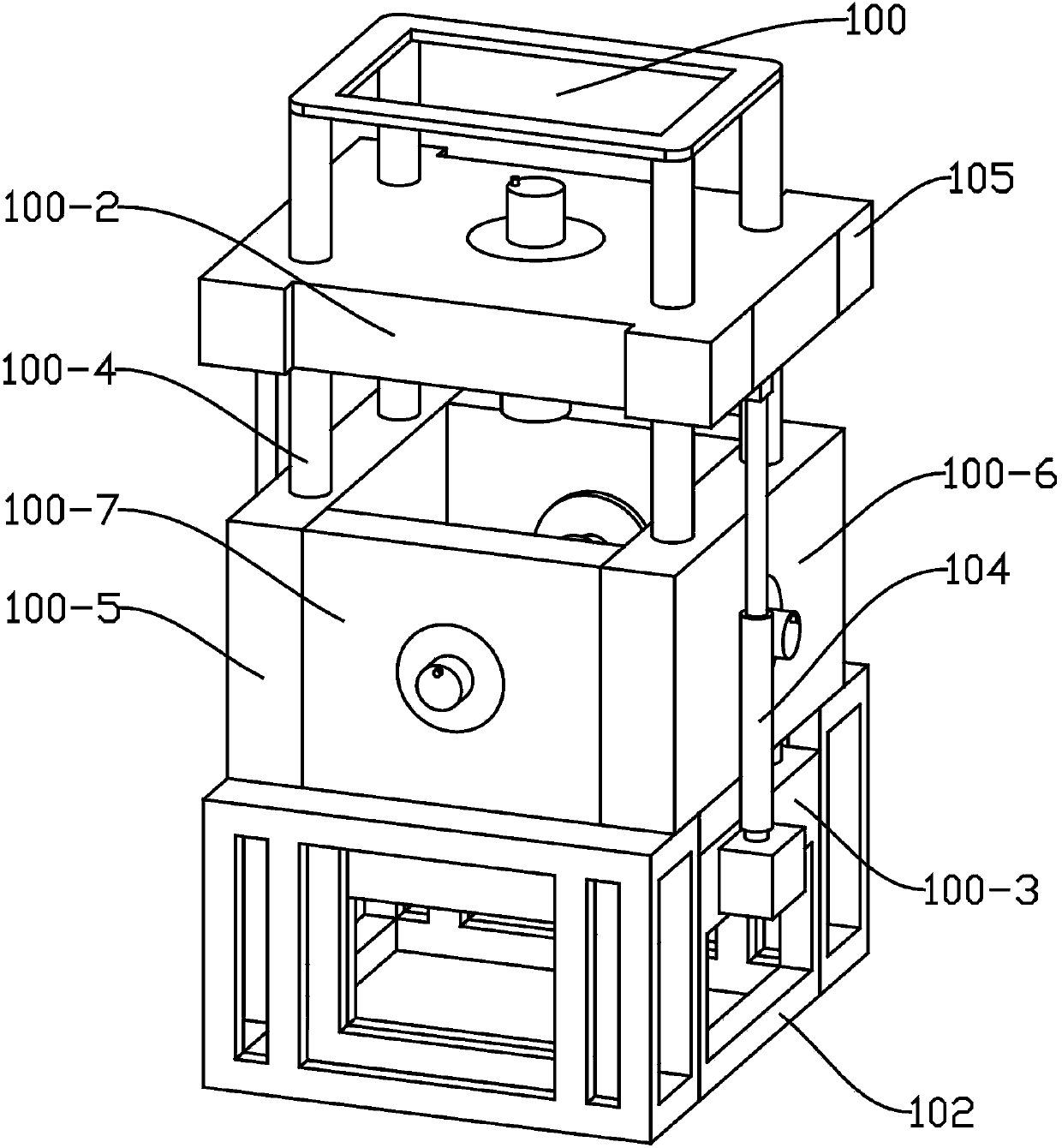

[0071] see figure 1 , figure 2 , image 3 , a triaxial testing machine is provided in this embodiment, including a loading frame 100, a test piece box 101, a base 102, six actuators 103, a lifting cylinder 104, and a locking cylinder 105; wherein,

[0072] The base 102 includes an axial frame base 102-1, a horizontal frame base 102-2, and a specimen box base 102-3. The axial frame base 102-1, the horizontal frame base 102-2, and the specimen box base 102 -3 are set on three separate sets of foundations. Since the test piece box 101 and the frames in all directions will be slightly deformed during the test, in order to avoid mutual influence, the axial frame base 102-1, the horizontal frame base 102-2 and the test piece box base 102-3 are respectively It is set on three sets of independent foundations; in this embodiment, the foundations corresponding to the axial frame base 102-1 and the horizontal frame base 102-2 respectively adopt anti-seismic foundation structures, and...

Embodiment 2

[0086] Such as Figure 11 or as Figure 12 As shown, the main difference between this embodiment 2 and the above-mentioned embodiment 1 is that in this embodiment, the test piece box 101 is a true triaxial test piece box 112, and the true triaxial test piece box 112 includes a custom Cardiac head 112-1, finale shaft 112-2, pressing block 112-3, box body 112-4, box body support 112-5, test piece deformation sensor 119, wherein,

[0087] The box body 112-4 is surrounded by a cuboid or cube structure by the upper cover, the lower cover and the side walls; each surface of the box body 112-4 is provided with a self-centering indenter 112-1, The self-centering indenter 112-1 is connected to one end of the final shaft 112-2, and the other end of the final shaft 112-2 passes through the box body 112-4, extends into the box body 112-4, and is connected to the On the pressing block 112 - 3 , the pressing block 112 - 3 is used to press against one surface of the test piece 106 . In th...

Embodiment 3

[0092] Such as Figure 14 or as Figure 15 As shown, the main difference between this embodiment 3 and the above-mentioned embodiment 1 is that in this embodiment, the test piece box 101 is a rockburst test piece box 113, and the rockburst test piece box 113 includes a self-centering pressure Head 112-1, finale shaft 112-2, pressing block 112-3, movable pressing block 113-3, box body 112-4, box body bracket 112-5, wherein,

[0093]The box body 112-4 has a cuboid or cube structure. One side of the box body 112-4 is not closed or is provided with an opening, which is convenient for observing rockburst phenomena. In the side surface, the corresponding actuator 103 The movable pressing block 113-3 is aligned with the test piece 106, and the load is transmitted to the test piece 106. The movable pressing block 113-3 is provided with a spherical groove 114 for compensating the force of the actuator 103. The non-perpendicularity error between the loading direction and the surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com