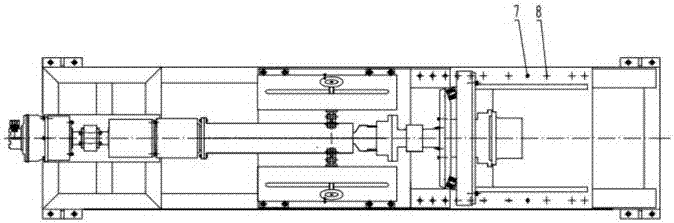

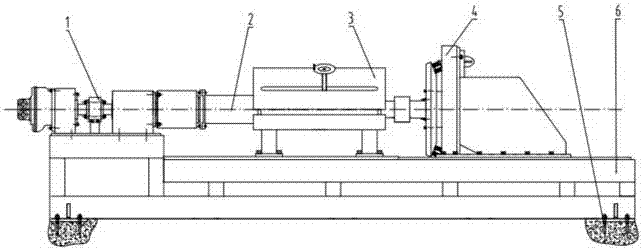

Test stand for testing performance of dynamic directional rotary steering drilling tool

A technology of rotary steerable drilling and dynamic pointing, which is applied in the field of petroleum drilling engineering and can solve problems such as inability to break through and lack of key technologies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

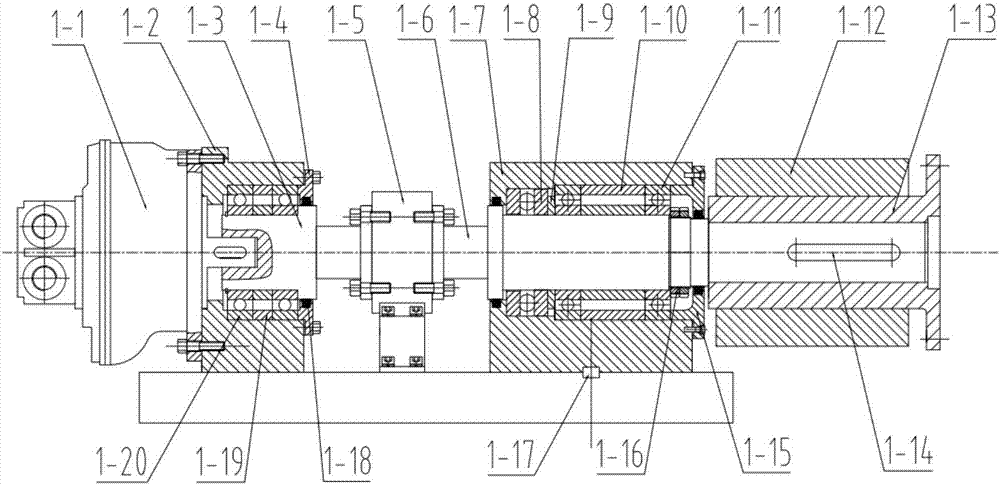

Embodiment 1

[0046] If WOB needs to be applied to the tool, the oil pump will pressurize the oil chamber on the right through oil holes 24-15. The oil pressure pushes the hollow shaft 4-16 of the cylinder to transmit the axial force through the cover 4-23, the pressure sensor 4-7, the retaining ring 4-25, the thrust ball bearing 1 4-26, the flange 2 4-4, the flange A 4-3 is passed to the drill 4-1. If unloading is required, oil hole 2 4-15 first releases the pressure, and then the oil pump pressurizes the left oil chamber through oil hole 1 4-13 to achieve the unloading effect.

Embodiment 2

[0048] If the torque load needs to be loaded, the hydraulic pump 4-18 passes the output shaft 4-20, the flat key four 4-19, the load shaft 4-6, the flat key two 4-5, the flange one 4-3, the flange two 4- 4. The flat key one 4-2 is passed to the drill bit 4-1.

Embodiment 3

[0050] If the drill bit 4-1 needs to swing during loading, the drill bit 4-1 drives everything except the baffle to swing in any direction. The baffles 4-11 counteract the axial reaction force generated by the axial force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com