Expansive type high-molecular polymer grouting reinforcement material and preparation method thereof

A high molecular polymer and grouting reinforcement technology, applied in the field of engineering materials, can solve the problems of brittle solids, poor reinforcement, slow curing speed, etc., and achieve the effects of strong permeability, enhanced strength, and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

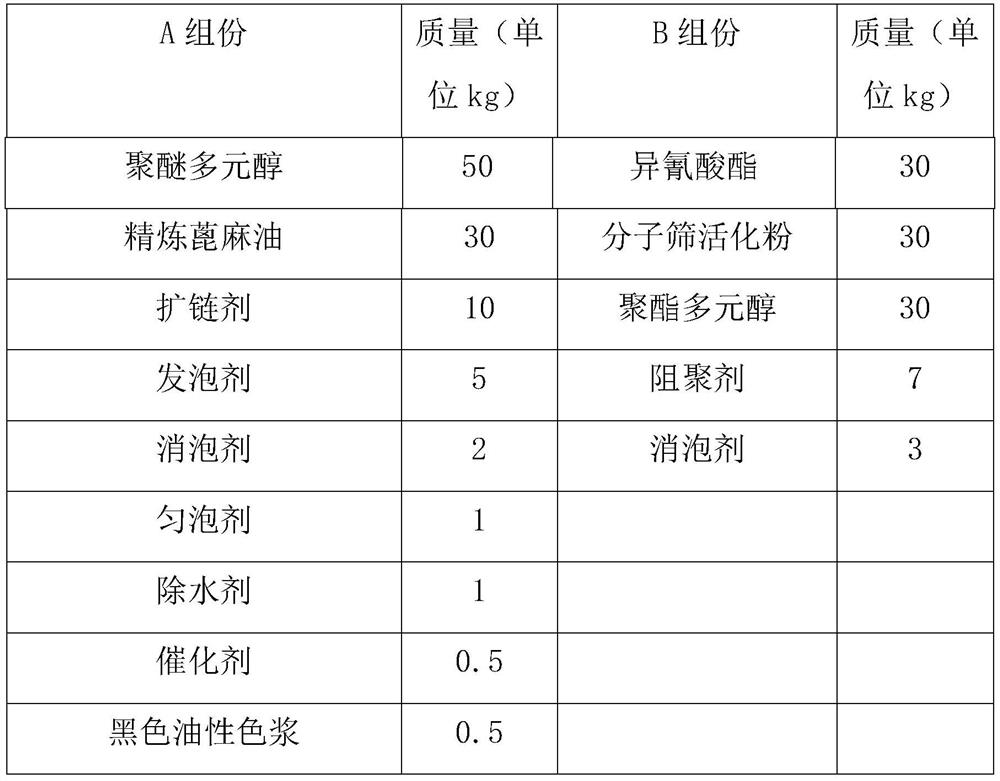

[0040] 1. Material formula:

[0041] An expanded polymer grouting reinforcement material, which is made by mixing the following components according to their respective masses:

[0042]

[0043] Among them, the polyether polyol is prepared from 40kg of 220 type 12056E polyether polyol and 50kg of 330 type 16075 polyether polyol;

[0044] The chemical formula of refined castor oil is C 57 h 104 o 9 , the hydroxyl value is 160-168mgKOH / g, and the ricinoleic acid content is 85%;

[0045] The chain extender is prepared from 40kg of 1,4-butanediol, 30kg of 1,6-hexanediol, and 10kg of 3,3,-dichloro-4,4,diaminodiphenylmethane;

[0046] Foaming agent is hydrated inorganic Na 2 SO 4 .10H 2 O;

[0047]The defoamer is a special defoamer for polyether polyurethane, with a molecular weight of 3000-3600 and a hydroxyl value of 50±5mgKOH / g;

[0048] Foam stabilizer is polydimethylsiloxane, chemical formula is (C 2 h 6 OSi)n;

[0049] Water removal agent is 3-ethyl-2-methyl-2-(...

Embodiment 2

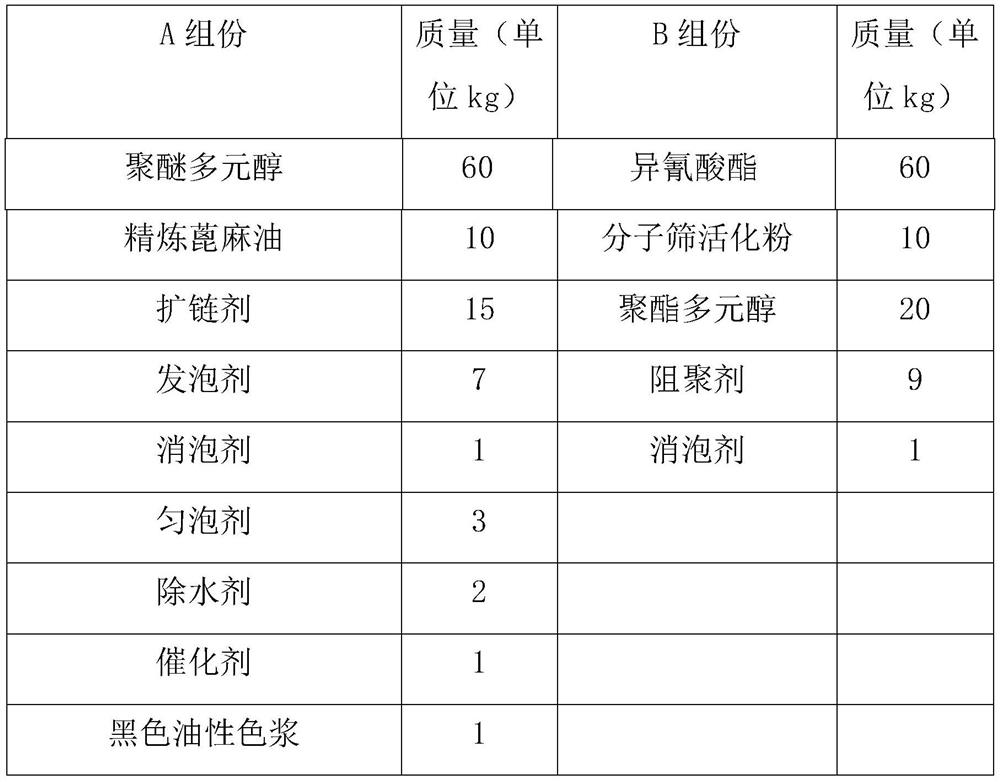

[0068] 1. Material formula:

[0069] An expanded polymer grouting reinforcement material, which is made by mixing the following components according to their respective masses:

[0070]

[0071] Among them, the polyether polyol is prepared from 60kg of 220 type 12056E polyether polyol and 30kg of 330 type 16075 polyether polyol;

[0072] The chemical formula of refined castor oil is C 57 h 104 o 9 , the hydroxyl value is 160-168mgKOH / g, and the ricinoleic acid content is 85%;

[0073] The chain extender is prepared from 50kg of 1,4-butanediol, 40kg of 1,6-hexanediol, and 20kg of 3,3,-dichloro-4,4, diaminodiphenylmethane;

[0074] Foaming agent is hydrated inorganic CaCl 2 .6H 2 O;

[0075] The defoamer is a special defoamer for polyether polyurethane, with a molecular weight of 3000-3600 and a hydroxyl value of 50±5mgKOH / g;

[0076] Foam stabilizer is polydimethylsiloxane, chemical formula is (C 2 h 6 OSi)n;

[0077] Water removal agent is 3-ethyl-2-methyl-2-(3-m...

Embodiment 3

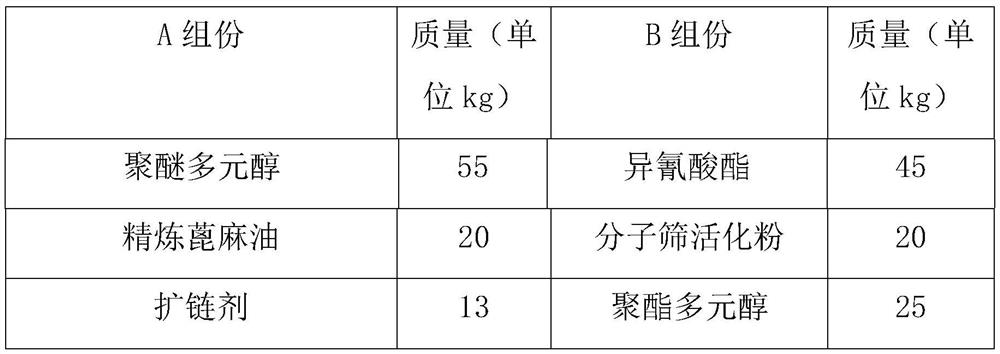

[0096] 1. Material formula:

[0097] An expanded polymer grouting reinforcement material, which is made by mixing the following components according to their respective masses:

[0098]

[0099]

[0100] Among them, the polyether polyol is prepared from 50kg of 220 type 12056E polyether polyol and 40kg of 330 type 16075 polyether polyol;

[0101] The chemical formula of refined castor oil is C 57 h 104 o 9 , the hydroxyl value is 160-168mgKOH / g, and the ricinoleic acid content is 85%;

[0102] The chain extender is prepared from 45kg of 1,4-butanediol, 35kg of 1,6-hexanediol, and 15kg of 3,3,-dichloro-4,4, diaminodiphenylmethane;

[0103] Foaming agent is hydrated inorganic Na 2 SO 4 .10H 2 O;

[0104] The defoamer is a special defoamer for polyether polyurethane, with a molecular weight of 3000-3600 and a hydroxyl value of 50±5mgKOH / g;

[0105] Foam stabilizer is polydimethylsiloxane, chemical formula is (C 2 h 6 OSi)n;

[0106] Water removal agent is 3-ethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com