Load box capable of satisfying net slurry inside (outside) of cylinder

A load box and cylinder technology, applied in the field of load boxes, can solve the problems of reduced final setting strength of slurry, inability to drain liquid, reduce slurry concentration, etc., and achieve the effect of increasing filling rate, ensuring strength and integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] It should be noted that, in the following embodiments of the present invention, the orientation words are described according to the drawings, which do not constitute a limitation to the present invention.

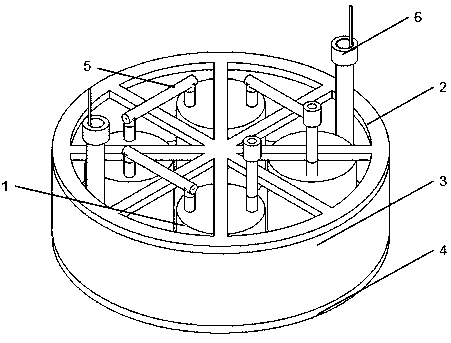

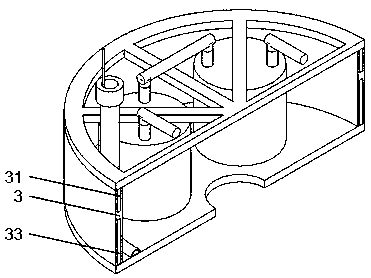

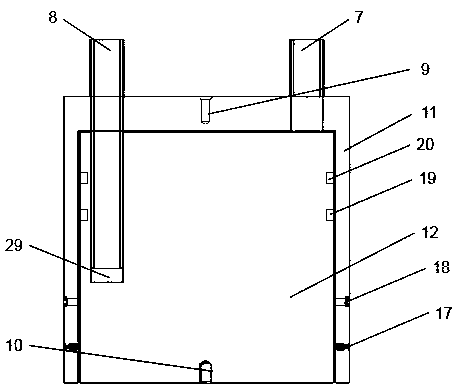

[0042] Attached below Figure 1-9 The present invention is further described in detail: a load box that satisfies the internal (outside) cleaning of the cylinder, such as Figure 1-2 As shown, it is composed of a hydraulic device 1, an upper plate 2, a waterproof connecting guard plate 3, a lower plate 4, a connecting pipe 5 and a pressure-limiting explosive grouting device 6; the hydraulic device 1 is installed between the upper plate 2 and the lower plate 3 , is multiple, connected in series through the connecting pipe 5; the upper plate 2 is a rigid lattice structure, and the waterproof connecting guard plate 3 is made of flexible waterproof material, which is H-shaped, and is movably connected with the upper plate 2 and the lower plate 4, and is pressure-limited...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com