Drawing type bottom dump car

A technology for pulling and unloading mine trucks, applied in the field of mining machinery, can solve the problems of difficulty in lifting and unloading bulk materials, low operation efficiency of mine trucks, etc. The effect of the ability to uninstall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

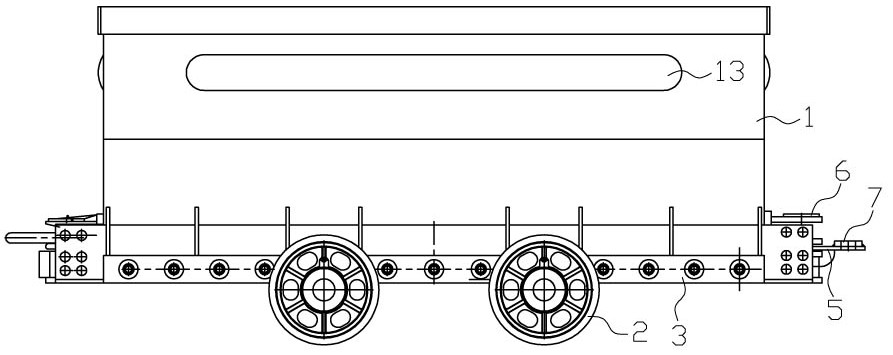

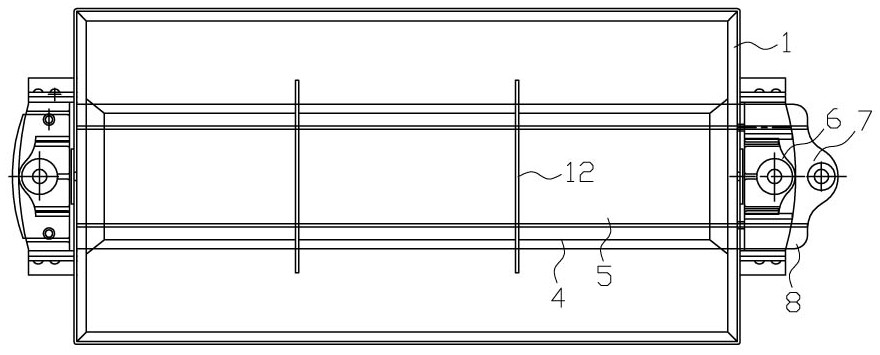

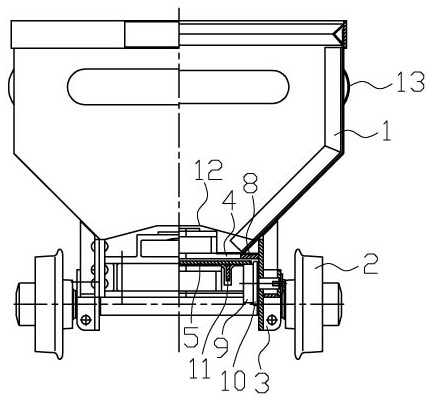

[0009] like figure 1 , 2 As shown in and 3, the pull-out bottom unloading truck includes a car box 1, wheels 2 and a frame 3. The top of the car box 1 is open, the bottom is provided with a discharge port 4 and a material door 5, and the end of the frame 3 is provided with traction Part 6, the car box 1 and the wheel 2 are respectively fixed on the top and bottom through the frame 3, and it is characterized in that the material door 5 is a pull-out structure, and one end of the material door 5 is provided with a pulling part 7, and the frame 3 is located at There are longitudinal baffles 8 below the discharge port 4 of the car box 1 and on both sides of the discharge port 4, and a row of guide wheels 9 are arranged below each baffle 8. The wheel rim 10, the guide wheel 9 is longitudinally fixed on the frame 3 in a straight line, and there is a gap for the material door 5 to be inserted between the guide wheel 9 and the baffle 8, and the material door 5 is inserted into the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com