System and method for instant hydrogen production and power generation

A technology of power generation system and power generation sub-system, applied in the direction of circuits, fuel cells, electrical components, etc., can solve the problems of poor mobility, inconvenient portability, constraints on hydrogen production and portability of power generation equipment, and achieve the effect of improving portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

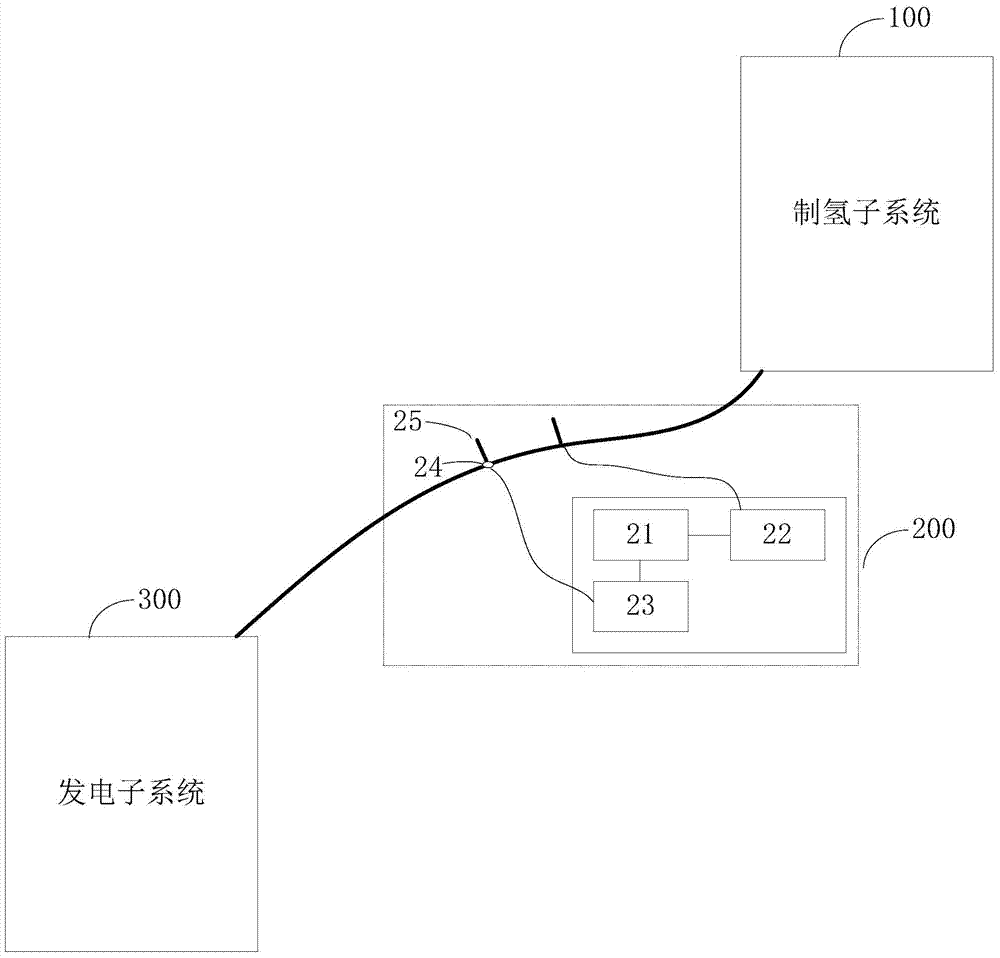

[0065] see figure 1 , the present invention discloses an instant hydrogen production power generation system, said system includes: hydrogen production subsystem 1, air pressure regulation subsystem 2, power generation subsystem 3, hydrogen production subsystem 1, air pressure regulation subsystem 2, power generation subsystem 3 connect in sequence. The hydrogen production subsystem 1 uses methanol water to prepare hydrogen, and transmits the produced hydrogen to the power generation subsystem 3 in real time through the transmission pipeline; the transmission pipeline is provided with an air pressure adjustment subsystem 2, which is used to adjust the The air pressure; the power generation subsystem 3 utilizes the hydrogen produced by the hydrogen production subsystem to generate electricity.

[0066] The hydrogen production subsystem uses methanol water to produce hydrogen, and the hydrogen production subsystem includes a solid hydrogen storage container, a liquid storage co...

Embodiment 2

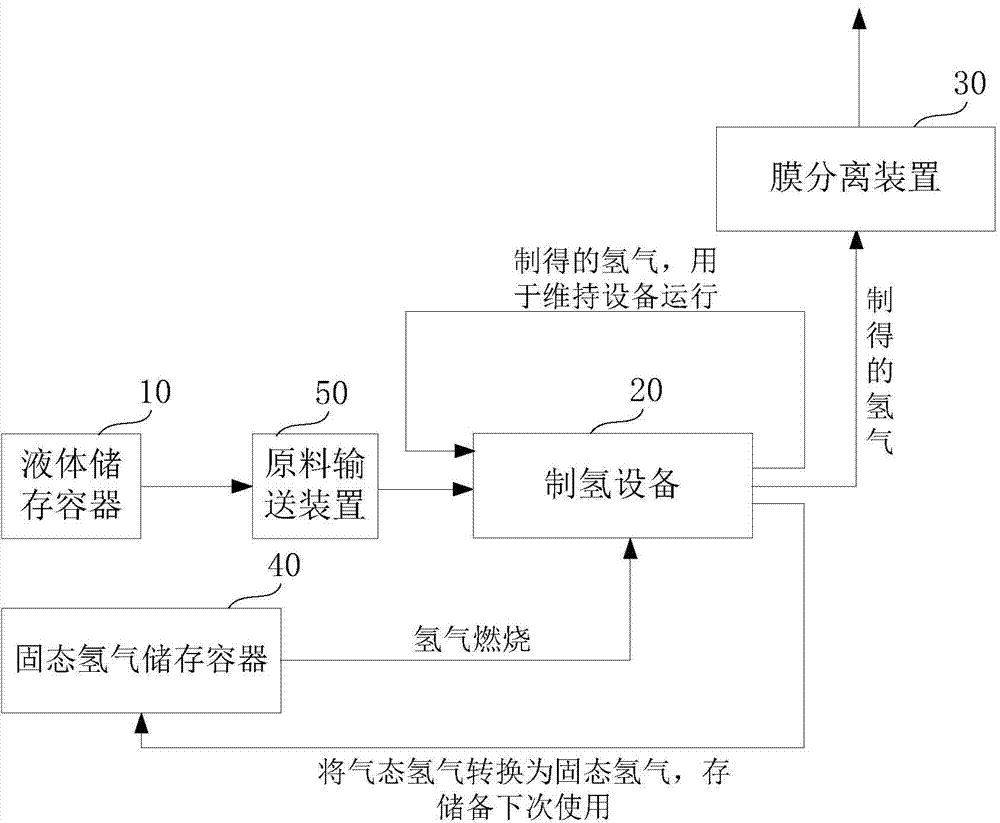

[0079] The difference between this embodiment and Embodiment 1 is that in this embodiment, please refer to figure 2 , the hydrogen production subsystem uses methanol water to produce hydrogen, and the hydrogen production subsystem includes a solid hydrogen storage container 40 , a liquid storage container 10 , a raw material delivery device 50 , a hydrogen production equipment 20 , and a membrane separation device 30 .

[0080] The solid hydrogen storage container 40 and the liquid storage container 10 are respectively connected to the hydrogen production equipment 20; liquid methanol and water are stored in the liquid storage container 10, and solid hydrogen is stored in the solid hydrogen storage container 40.

[0081] When the hydrogen production system is started, the solid hydrogen in the solid hydrogen storage container 40 is converted into gaseous hydrogen through the gasification module, and the gaseous hydrogen is burned to release heat to provide start-up heat energy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com