Movable hydrogen source preparation method

A hydrogen source and hydrogen technology, applied in the direction of hydrogen production, etc., can solve the problems of transportation safety hazards, low production efficiency, complex processes, etc., and achieve the effects of reducing production costs, improving production efficiency, and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

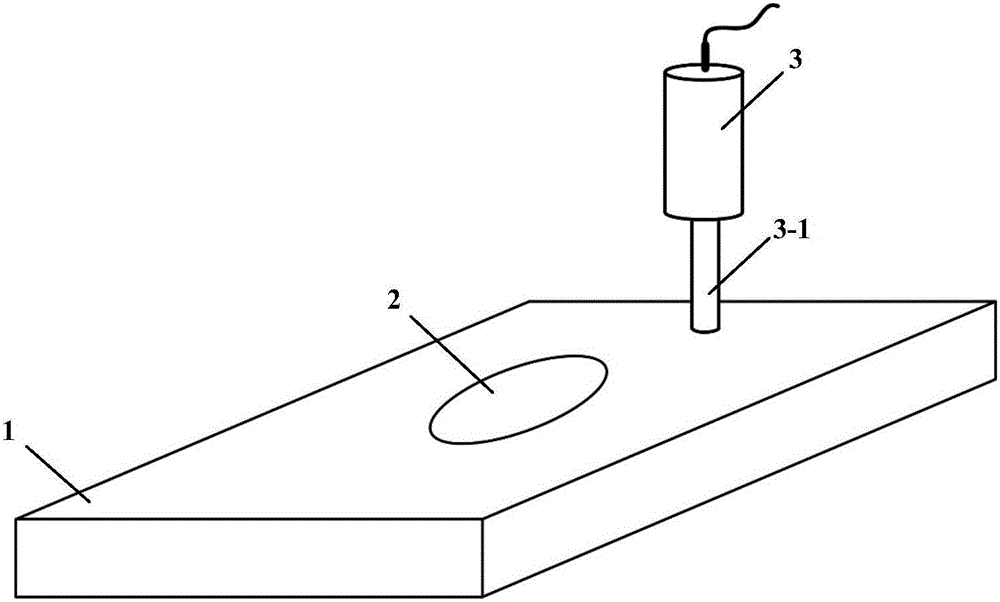

[0029] Specific implementation mode one: combine figure 1 To illustrate this embodiment, a method for preparing a mobile hydrogen source in this embodiment includes the following preparation steps:

[0030] Step 1: Prepare Aluminum Plate 1:

[0031] Fix the metal aluminum plate 1 with a thickness of 0.1-30mm, scrub the upper surface of the aluminum plate 1 with an organic solvent to remove oil stains and expose a clean surface, and set aside;

[0032] Step 2: Metal gallium backup:

[0033] Take an appropriate amount of gallium metal and place it in a beaker, heat the beaker until the gallium metal melts into a liquid state, and set aside;

[0034] Step 3: Heating Aluminum Plate 1:

[0035] Pour the liquid gallium 2 in step 2 onto the upper surface of the aluminum plate 1 in step 1, and heat the area covered with the liquid gallium 2 from below the aluminum plate 1 to ensure that the metal gallium is always in a liquid state. At the same time, when the aluminum plate 1 is he...

specific Embodiment approach 2

[0044] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the upper surface of the aluminum plate 1 in Step 1 of this embodiment is scrubbed with an acetone organic solvent. With such arrangement, the oil stain on the upper surface of the aluminum plate 1 can be effectively removed to prevent the oil stain from hindering the liquid gallium 2 from entering the aluminum plate 1 . Other compositions and connections are the same as in the first embodiment.

[0045] The organic solvent in this embodiment is absolute ethanol, and the oil stain on the upper surface of the aluminum plate 1 can also be removed by absolute ethanol.

specific Embodiment approach 3

[0046] Specific implementation mode three: combination figure 1 To illustrate this embodiment, in step 2 of this embodiment, 8ml-12ml of liquid gallium 2 is placed in a beaker, preferably 10ml. Such setting ensures that the liquid gallium 2 can completely cover the exposed fresh aluminum substrate after milling. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

[0047] Specific implementation mode four: combination figure 1 To describe this embodiment, the end of the ultrasonic tool head 3-1 of the ultrasonic vibration device 3 in Step 5 of this embodiment is pressed into the aluminum plate by 0.03mm-0.07mm, preferably 0.05mm. With such a setting, the ultrasonic vibration can be effectively transmitted to the aluminum plate without damaging the ultrasonic tool head, so that the density of the aluminum plate fluctuates with the change of sound pressure. Other compositions and connections are the same as those in Embodiment 1, 2 or 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com