Chemical extraction method and apparatus for metal gallium

An extraction device and gallium metal technology, applied in the field of gallium metal chemical extraction methods and devices, can solve the problems of difficult to be widely used in industrial production, low efficiency of extraction devices, poor extraction effect, etc., achieve remarkable purification effect, easy promotion, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

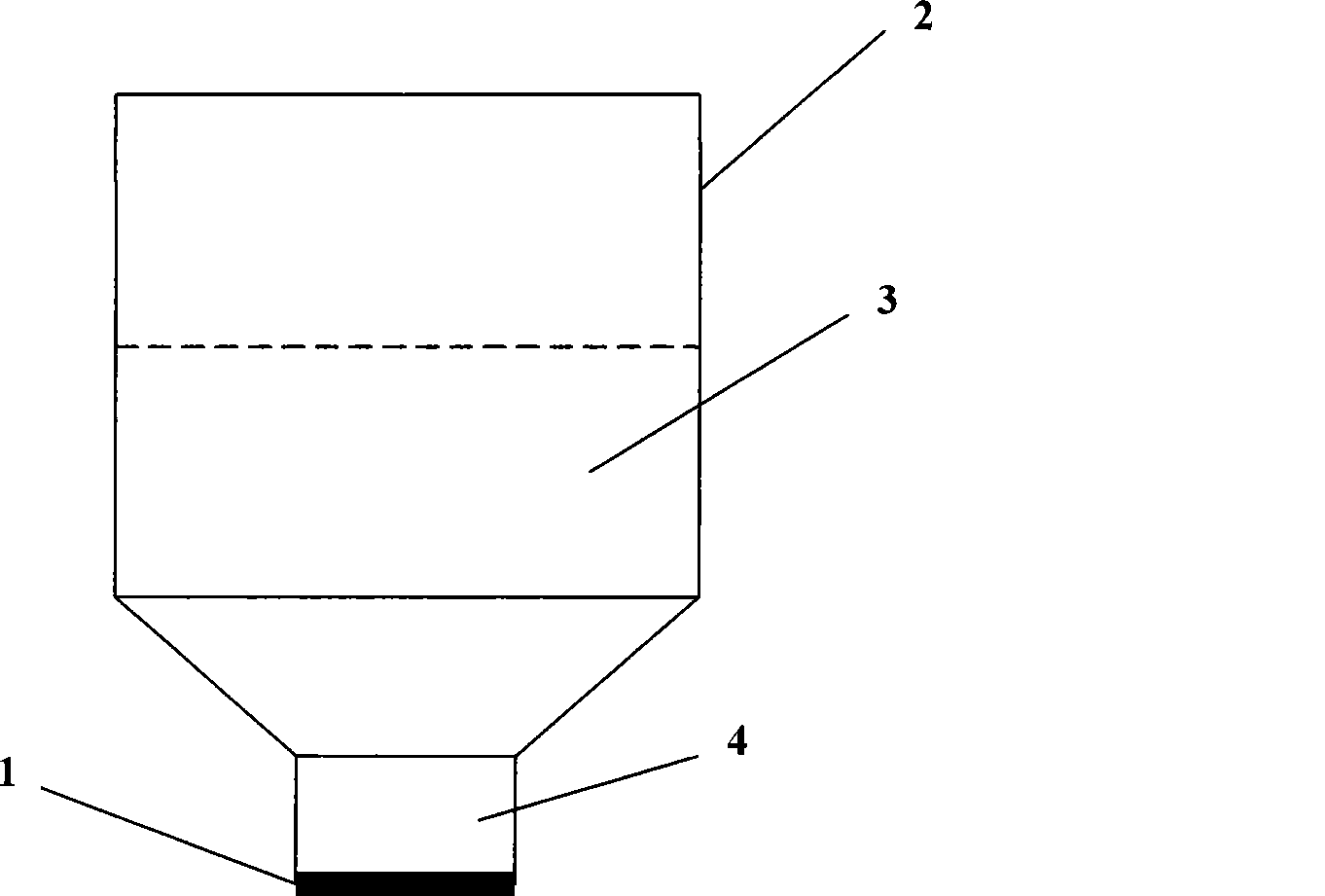

[0012] Embodiment 1: as figure 1 As shown, a gallium metal chemical extraction device includes an extraction vessel 2, the bottom of the extraction vessel 2 has a hole 4, compressed gas is blown into the extraction vessel 2 through the hole 4, and the hole 4 is provided with a one-way valve The sheet 1 makes the compressed gas flow in one direction and prevents the liquid 3 in the extraction container 2 from flowing out. The compressed gas can be an inert gas or purified air. When the compressed gas is blown in from the bottom of the extraction vessel, it will cause violent agitation to the liquid gallium in the lower part of the vessel, making the liquid gallium with a higher density chemically react with the aqueous solution with a lower density. The reagents are fully contacted to form an air flow to disturb the extraction effect, which greatly improves the extraction efficiency. According to the experimental data, the liquid gallium is extracted three times by the device ...

Embodiment 2

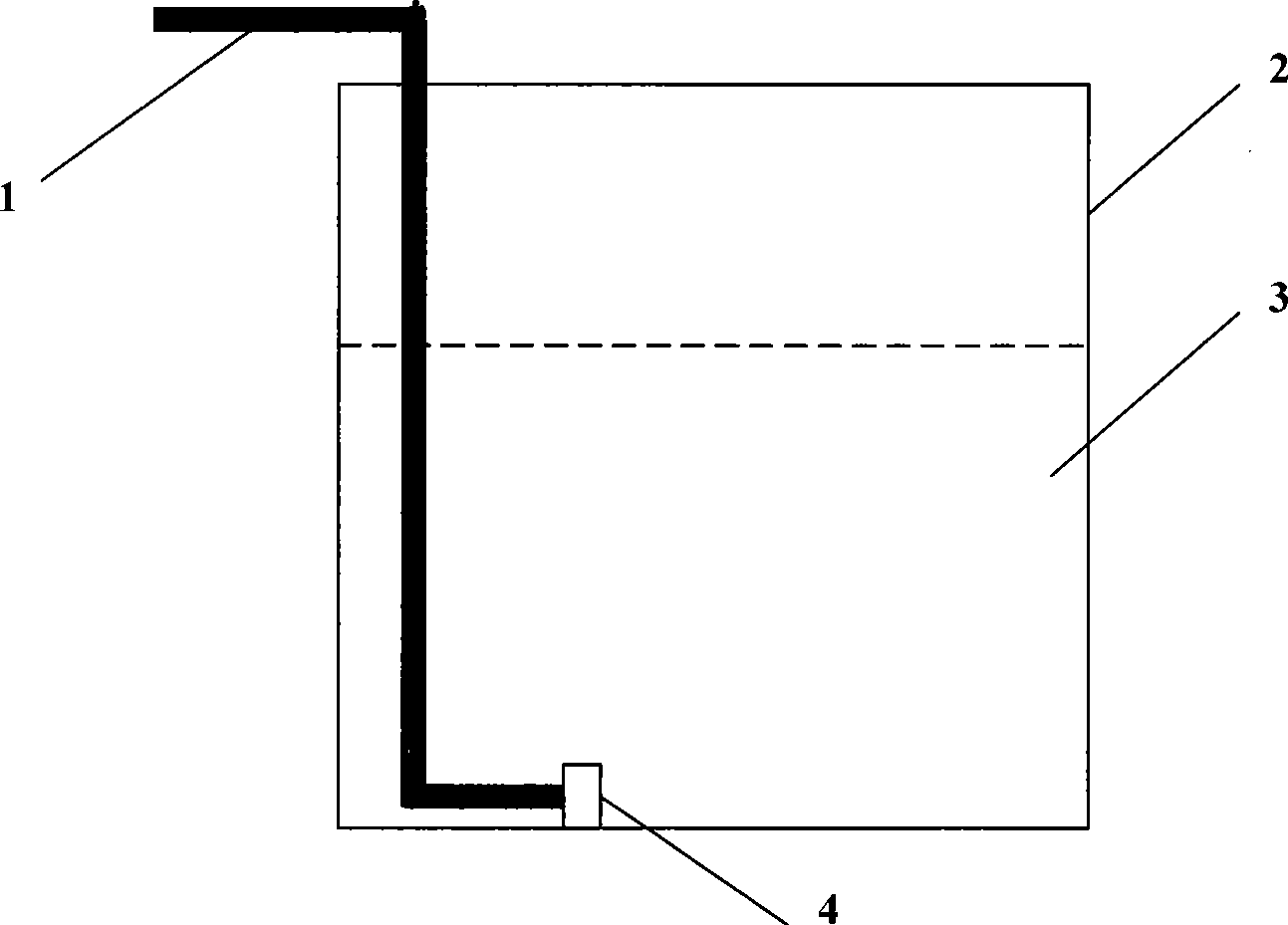

[0013] Embodiment 2: as figure 2 As shown, a gallium metal chemical extraction device includes an extraction vessel 2, a unidirectional conduit 1 is provided at the bottom of the extraction vessel 2, and compressed gas is blown into the extraction vessel 2 through the conduit 1. The conduit is provided with a one-way valve 4 to allow the compressed gas to flow in one direction and prevent the liquid 3 in the extraction vessel 2 from entering the conduit 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com