Electrode lead for electrolyzing metal gallium

An electrode lead, electrolytic metal technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of impurity, increase production cost, and increase capital, and achieve the effect of improving effect, reducing consumption and eliminating pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

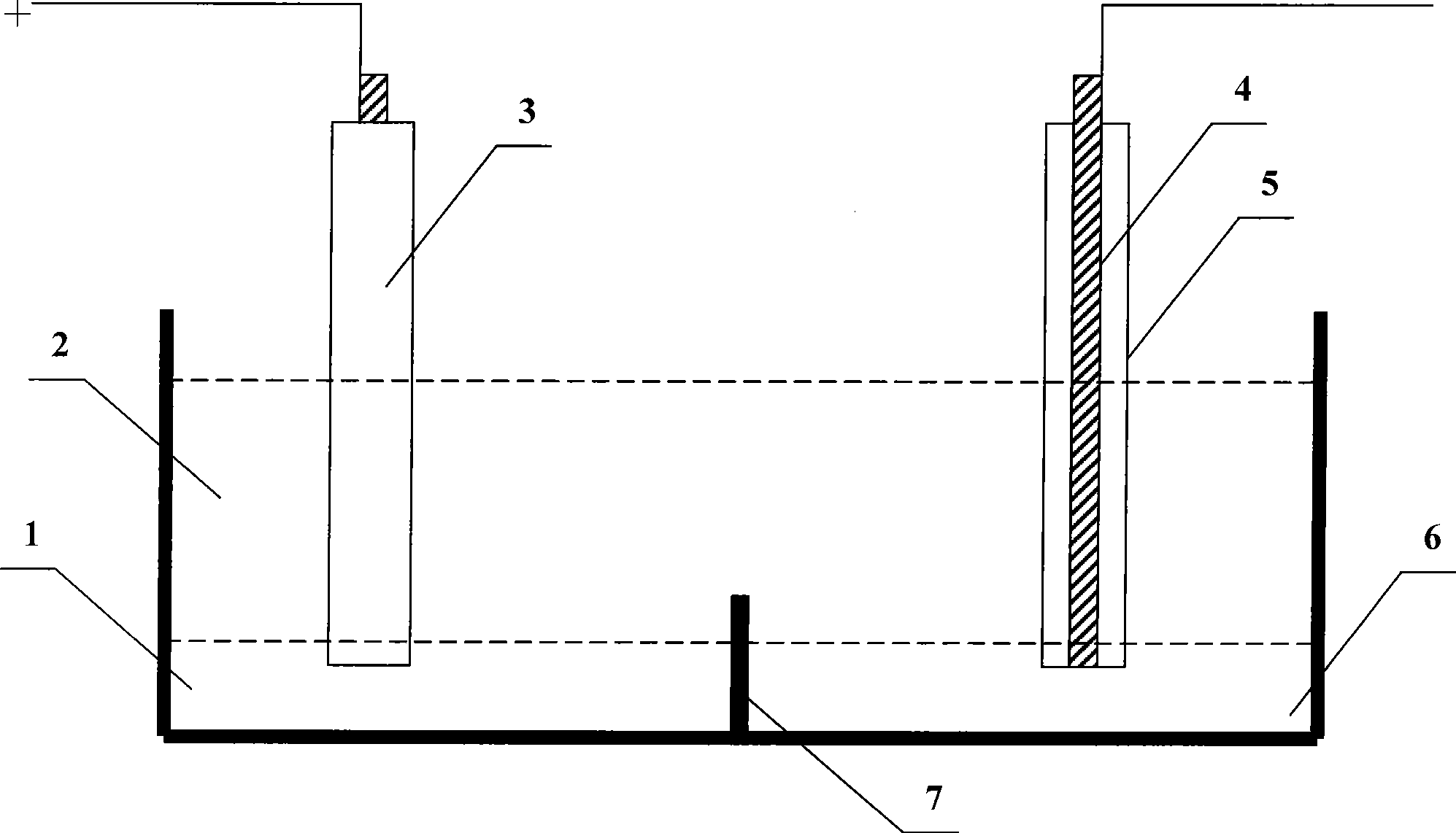

[0013] Embodiment 1: as figure 1 As shown, in the electrolytic cell used for the electrolysis of gallium, the anode electrode area 1 and the cathode electrode area 6 are separated by the electrode area separator 7, and gallium to be electrolytically purified and refined gallium are respectively placed in the anode electrode area 1 and the cathode electrode area 6. The cathode and anode electrode wires are respectively inserted into the solution 2, and the electrode wires are made of solid metal gallium 4, and a cooling device 5 is provided outside the solid metal gallium 4, and the cooling device 5 cools the solid metal gallium 4 through the circulating flow of cooling liquid to maintain the form of solid gallium , because the melting point of metal gallium is 30°C, so the solid gallium lead which is in contact with the liquid gallium electrode at 50°C during electrolysis must be kept in a strong freezing environment for a long time, so that the temperature of the solid gallium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com