Lubricant as well as preparation method and application thereof

A lubricant, liquid metal technology, applied in the field of lubrication, can solve the problems of limited application, mercury human body and environmental hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of described lubricant provided by the invention, described method comprises the steps:

[0024] 1) Put the weighed metal components into the same container and heat to melt the metal components into a liquid state;

[0025] 2) Ultrasonic mixing in a water bath at 50°C-100°C for 1 hour to 1.5 hours to make it evenly mixed;

[0026] 3) Inject NaOH solution or HCl solution into a container containing liquid metal, and use a magnetic stirrer to stir for 10 minutes to 20 minutes in a water bath environment of 50°C-100°C, so that the oxides on the surface of the liquid metal are fully reacted; The mass percent concentration of NaOH solution or HCl solution is 5%-8%;

[0027] 4) After the reaction is complete, the solution is separated to prepare a gallium-based liquid metal lubricant.

[0028] According to the national standard GB / T12583-1998 lubricant extreme pressure performance test method, the extreme pressure performance of gallium-based liquid ...

Embodiment 1

[0030] Use pure liquid metal gallium as lubricant (the melting point of pure gallium is 29.8°C).

[0031] According to the national standard GB / T12583-1998 lubricant extreme pressure performance test method, the extreme pressure performance of the gallium lubricant was tested. The test found that the sintering load of the gallium lubricant was greater than 10000N (the maximum load of the four-ball friction testing machine used in the experiment was 10000N). As a comparison, according to the national standard GB / T12583-1998, the gear oil GL-585W / 90 and the extreme pressure grease MobilithSHC1000Special were tested for extreme pressure performance. The test shows that the sintering load of gear oil GL-585W / 90 is 2452N, while the sintering load of MobilithSHC1000Special is 6080N. The average wear scar diameter of the steel balls corresponding to MobilithSHC1000Special under the load of 6080N is 5.3mm. According to the provisions of GB / T12583-1998, the load applied when no sinte...

Embodiment 2

[0033] According to the method proposed in the summary of the invention, liquid metals with mass fractions of Ga, In, and Sn of 64%, 24%, and 12% were prepared, denoted as Ga 64 In 24 sn 12 . Ga 64 In 24 sn 12 It has not solidified at a low temperature of -10°C (that is, its melting point is lower than -10°C). Ga measured on a Hotdisc thermal constant analyzer 64 In 24 sn 12 The thermal conductivity of a gear oil is 25.7W / m.K, and the measured thermal conductivity of a certain gear oil is 0.15W / m.K. Ga 64 In 24 sn 12 The thermal conductivity is much higher than ordinary lubricants. Gallium-based liquid metal lubricants can quickly conduct frictional heat, thereby effectively preventing the occurrence of gluing at the friction interface.

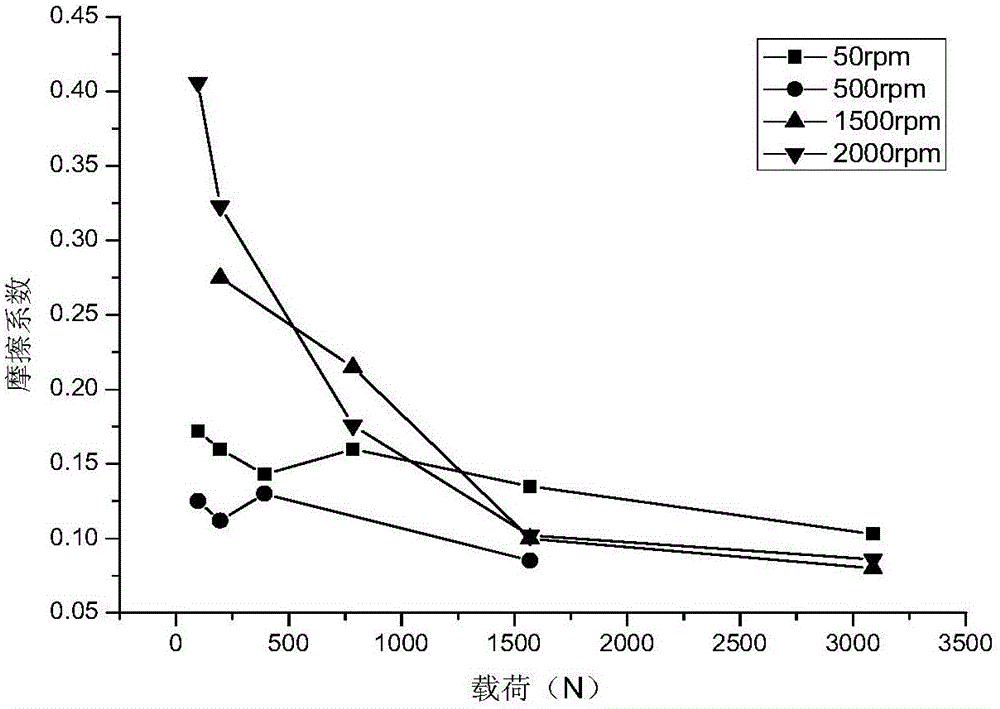

[0034] figure 1 Shown is the measured Ga 64 In 24 sn 12 The coefficient of friction of a lubricant as a function of speed and load. Visible, Ga 64 In 24 sn 12 A notable feature of the lubricant is its low coefficient of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com