Preparation method of gallium particles

A particle size and coolant technology, which is applied in the field of metal particle preparation, can solve the problems of difficulty in making gallium particles with uniform particle size and smoothness, complicated preparation devices and methods, and high supercooling degree of high-purity gallium. Easy to observe and simplify the effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

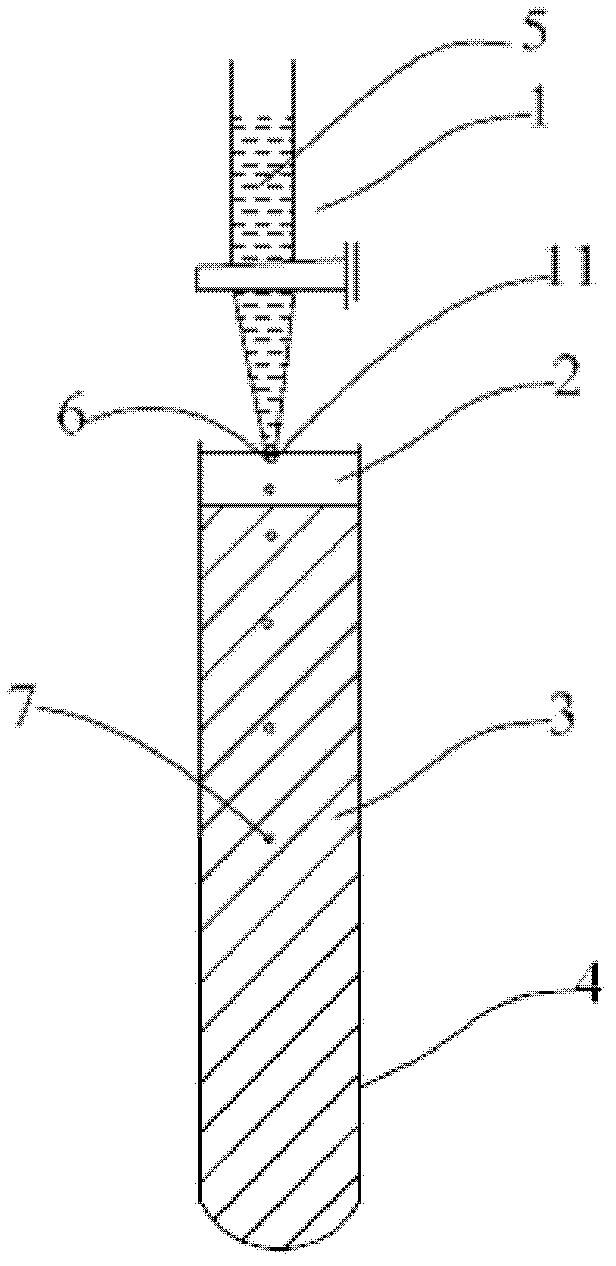

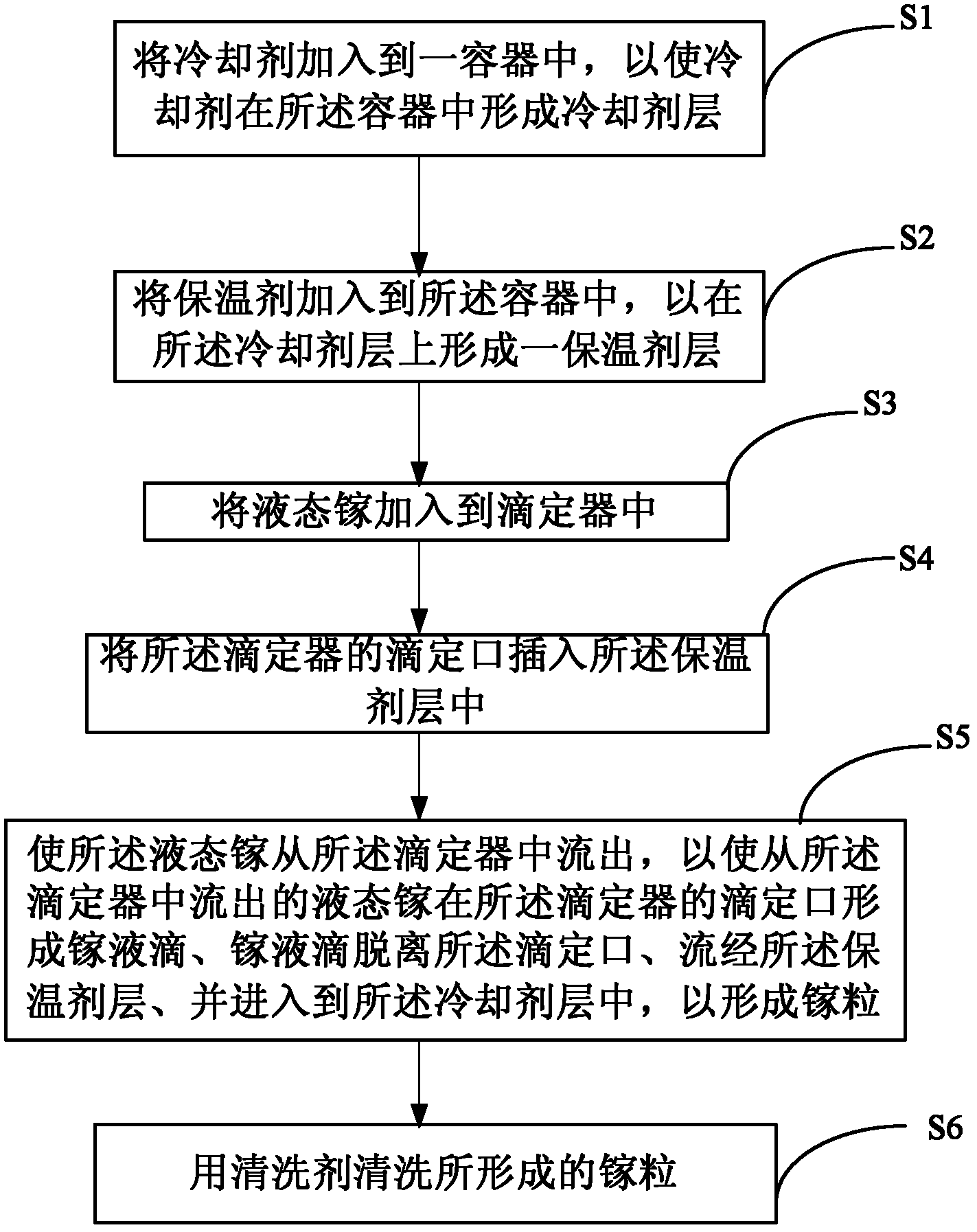

[0018] like figure 1 and figure 2 As shown, the preparation method of gallium particles according to the present invention comprises the steps of: adding the coolant into the container 4, so that the coolant forms the coolant layer 3 in the container 4 (step S1); adding the heat insulating agent into the container In 4, to form heat-retaining agent layer 2 (step S2) on coolant layer 3; Liquid gallium 5 is added in titrator 1 (step S3); The titration port 11 of titrator 1 is inserted in heat-retaining agent layer 2 ( Step S4); Make the liquid gallium 5 flow out from the titrator 1, so that the liquid gallium 5 flowing out from the titrator 1 forms a gallium drop 6 at the titration port 11 of the titrator 1, and the gallium liquid drop 6 breaks away from the titration port 11, Flow through the insulation layer 2 and enter the coolant layer 3 to form gallium grains 7 (step S5).

[0019] In the method for preparing gallium particles according to the present invention, it may fu...

Embodiment 1

[0035] A glass tube of Φ70mm*1200mm is used as the container 4; a CBS-1D full-automatic potentiometric titrator is used as the titrator 1; the liquid gallium used is 5N gallium, and the temperature of the liquid gallium is 50° C.; the coolant used is glycerol (glycerin) Alcohol) and water mixed solution, in the mixed solution of glycerin and water, glycerin accounts for 80% by volume, and water accounts for 20% by volume, and the water used is grade II high-purity water, and the mixed solution of glycerin and water passes through The temperature of the low-temperature refrigerator is controlled so that the temperature of the mixture of glycerin and water is minus 30°C; the insulating agent used is grade II high-purity water, and the temperature is 50°C; the layer thickness of the coolant layer 3 is 110cm; the layer thickness of the insulating agent layer 2 10cm; use grade II high-purity water as the cleaning agent; the titration port of the CBS-1D full-automatic potentiometric ...

Embodiment 2

[0037] A quartz tube of Φ70mm*1200mm is used as the container 4; an acid burette is used as the burette 1; the liquid gallium used is 5N gallium, and the temperature of the liquid gallium is 40°C; In the mixture of glycerin and water, glycerin accounts for 60% by volume, water accounts for 40% by volume, and the water is grade II high-purity water. The temperature of the mixture of glycerin and water is controlled by a low-temperature refrigerator, and the temperature is minus 20°C; The insulating agent used is grade II high-purity water at a temperature of 40°C; the layer thickness of the coolant layer 3 is 110cm; the layer thickness of the insulating agent layer 2 is 8cm; grade II high-purity water is used as the cleaning agent; The depth in the agent layer 2 is 0.7cm; the flow rate of the acid burette is controlled at 16ml / min; after cleaning, the residual coolant and cleaning agent on the surface of the gallium particles are blotted with filter paper, and the particle size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com