Purification method for gallium

A purification method and gallium metal technology, applied in the direction of improving process efficiency, etc., can solve the problems of increasing production cost, increasing gallium metal loss, consumption of chemical reagents and electric energy, etc., and achieve quality assurance, simple operation method, and easy automatic control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

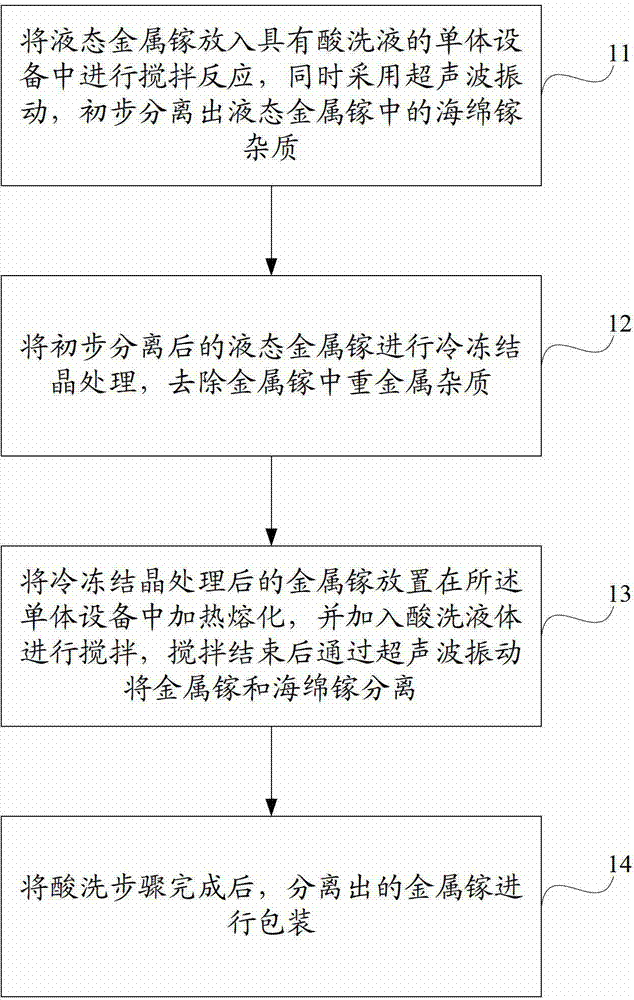

Method used

Image

Examples

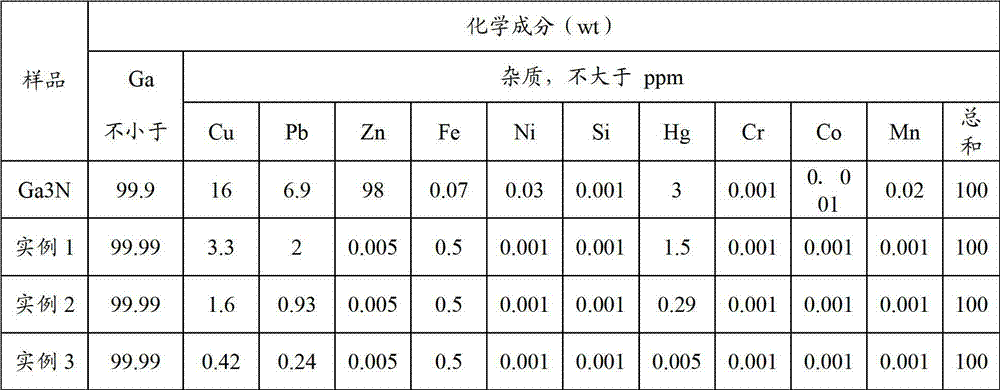

example 1

[0036] A kind of purification method of metal gallium provided by the invention:

[0037] (1) Place 100 kg of 3N liquid gallium metal in the monomer equipment, add 3N analytically pure hydrochloric acid, start stirring for a full stirring reaction for 1 hour, keep the temperature in the equipment at 40-50°C, and turn on the ultrasonic wave after the stirring reaction is completed Vibration equipment vibrates liquid metal gallium to separate gallium sponge; or ultrasonic vibration is performed while stirring and reacting to further separate impurity elements such as sponge.

[0038] (2) Freezing and crystallizing the separated liquid gallium metal. The temperature is kept between 20-30°C. After about 40-45% by weight of the liquid gallium is solidified, the solid is taken out and melted, and the freezing crystallization and melting process is repeated 3 times To purify, this step is mainly to further separate the heavy metal impurities.

[0039] (3) Put the gallium metal after...

example 2

[0042] A kind of purification method of metal gallium provided by the invention:

[0043] (1) Put 100 kg of 3N liquid gallium metal in the monomer equipment, add 4N analytically pure hydrochloric acid, turn on the stirring for a sufficient stirring reaction for 2 hours, keep the temperature in the equipment at 40-50°C, and turn on the ultrasonic wave after the stirring reaction is completed Vibration equipment vibrates and stratifies liquid metal gallium to separate metal impurity elements such as sponge gallium; or ultrasonic vibration is performed while stirring and reacting to separate impurity elements.

[0044] (2) Freezing and crystallizing the separated liquid gallium metal. The temperature is kept between 10-15°C. After about 45-50% of the weight of the liquid gallium is solidified, the solid is taken out and melted, and the process of freezing and crystallization is repeated 3 times. To purify, this step is mainly to further separate the heavy metal impurities.

[00...

example 3

[0048] According to the invention:

[0049](1) Put 100 kg of 3N liquid gallium metal in a single device, add 5N analytically pure hydrochloric acid, start stirring for a full stirring reaction for 3 hours, keep the temperature in the device at 40-50°C, and turn on the ultrasonic wave after the stirring reaction is completed Vibration equipment vibrates liquid metal gallium to separate impurity elements such as gallium sponge; or ultrasonic vibration is performed while stirring and reacting to further separate impurity elements such as gallium sponge.

[0050] (2) Freezing and crystallizing the separated liquid gallium metal. The temperature is kept between -1°C and 8°C. After about 35-40% of the weight of the liquid gallium is solidified, the solid is taken out and melted, and the freeze crystallization is repeated 3 times The melting process is used for purification, and this step is mainly to further separate heavy metal impurities.

[0051] (3) Put the gallium metal after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com