Magnetic nanometer-sized metal fluid and preparation method thereof

A metal fluid and magnetic nanotechnology, applied in the direction of nanotechnology, nanotechnology, magnetic liquid, etc., can solve the problems of complex operation and high energy consumption, and achieve the effects of high electrical conductivity, good fluidity, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

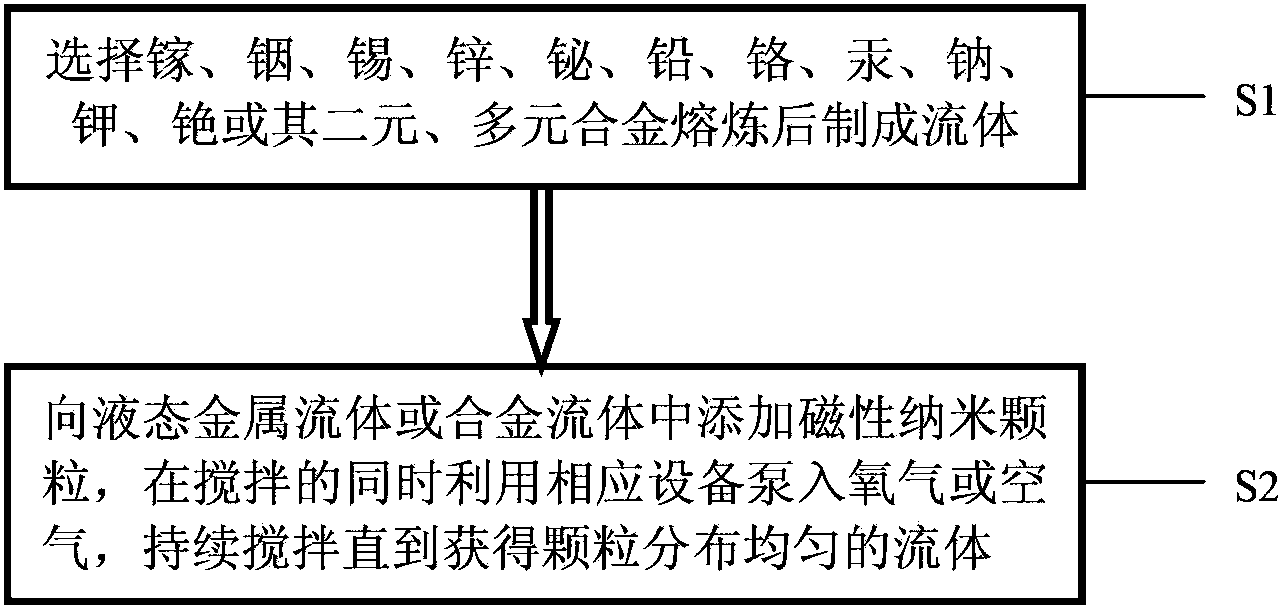

[0030] The present invention also provides a highly efficient and rapid preparation method of magnetic nano metal fluid, said method comprising the following steps:

[0031] Step S1, select metal gallium, indium, tin, zinc, bismuth, lead, chromium, mercury, sodium, potassium, cesium or their binary or multi-component alloys, and liquefy the metal / alloy by heating;

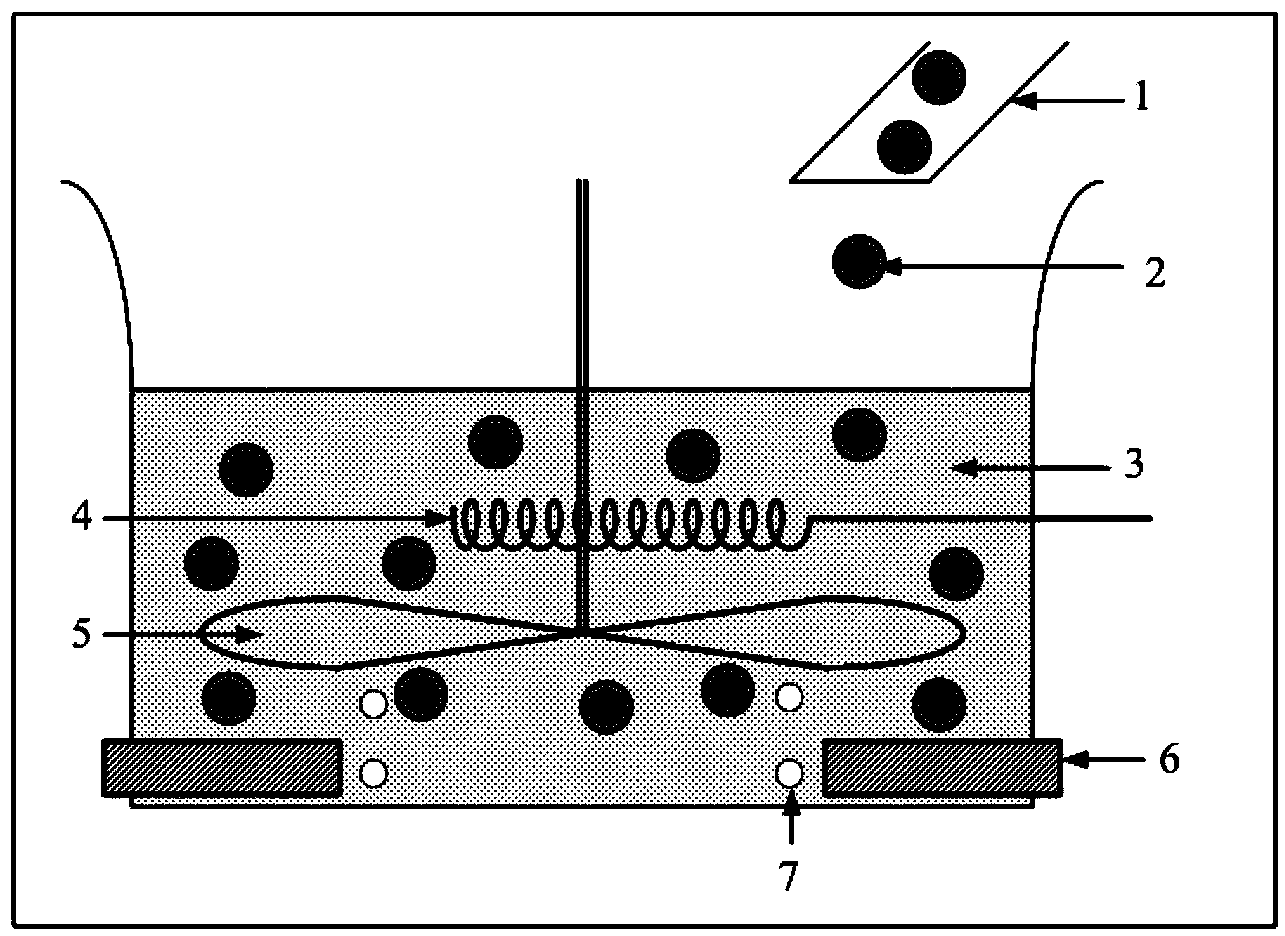

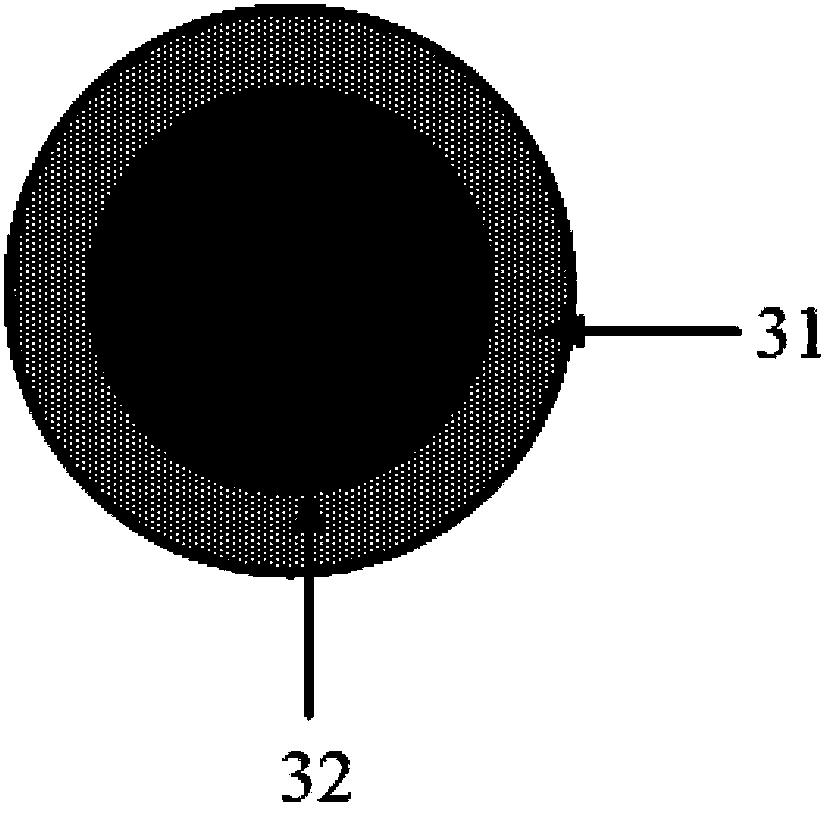

[0032] Step S2, adding magnetic nanoparticles to the liquid metal / alloy, pumping in air or oxygen while stirring, the stirring rate is 0-1000rpm, heating the liquid metal / alloy during the stirring process, the temperature is 25-1000°C, The volume ratio of oxygen in the pumped gas is 21% to 100%, and the stirring time is 10min to 10h to form a magnetic nano metal fluid.

[0033] Preferably, the nanoparticles in the step 2 are ferrite particles, metal particles, ferromagnetic nitride particles.

[0034] Preferably, the ferrite particles are Fe3O4, CoFe2O4, ZnFe2O4, MnZnFe2O4.

[0035] Preferably, the metal particle...

Embodiment 1

[0046] Measure 10ml of gallium metal, melt it into a liquid state through a hot water bath, continue heating in the air at a heating temperature of 50°C, and add nickel nanoparticles with a particle size of 50nm coated with silicon dioxide in a volume of 1ml to it . Start the stirring impeller at a stirring rate of 150rpm / min, while pumping air into it from the bottom. After stirring for 20 minutes, a relatively uniform magnetic nano metal fluid can be obtained.

Embodiment 2

[0048] According to the preparation method of Example 1, while stirring, oxygen with higher oxygen content, such as pure oxygen, is pumped into the bottom of the liquid metal through an oxygen generator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com