Preparation method of high-purity gallium

A high-purity and pure technology, applied in the field of preparation of inorganic semiconductor material raw materials, can solve the problems of dendrite bridging, crystal easily broken, affecting the grade of metal gallium, etc., to achieve the effect of increasing the solidification rate, large cooling area and reducing the number of purification times.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

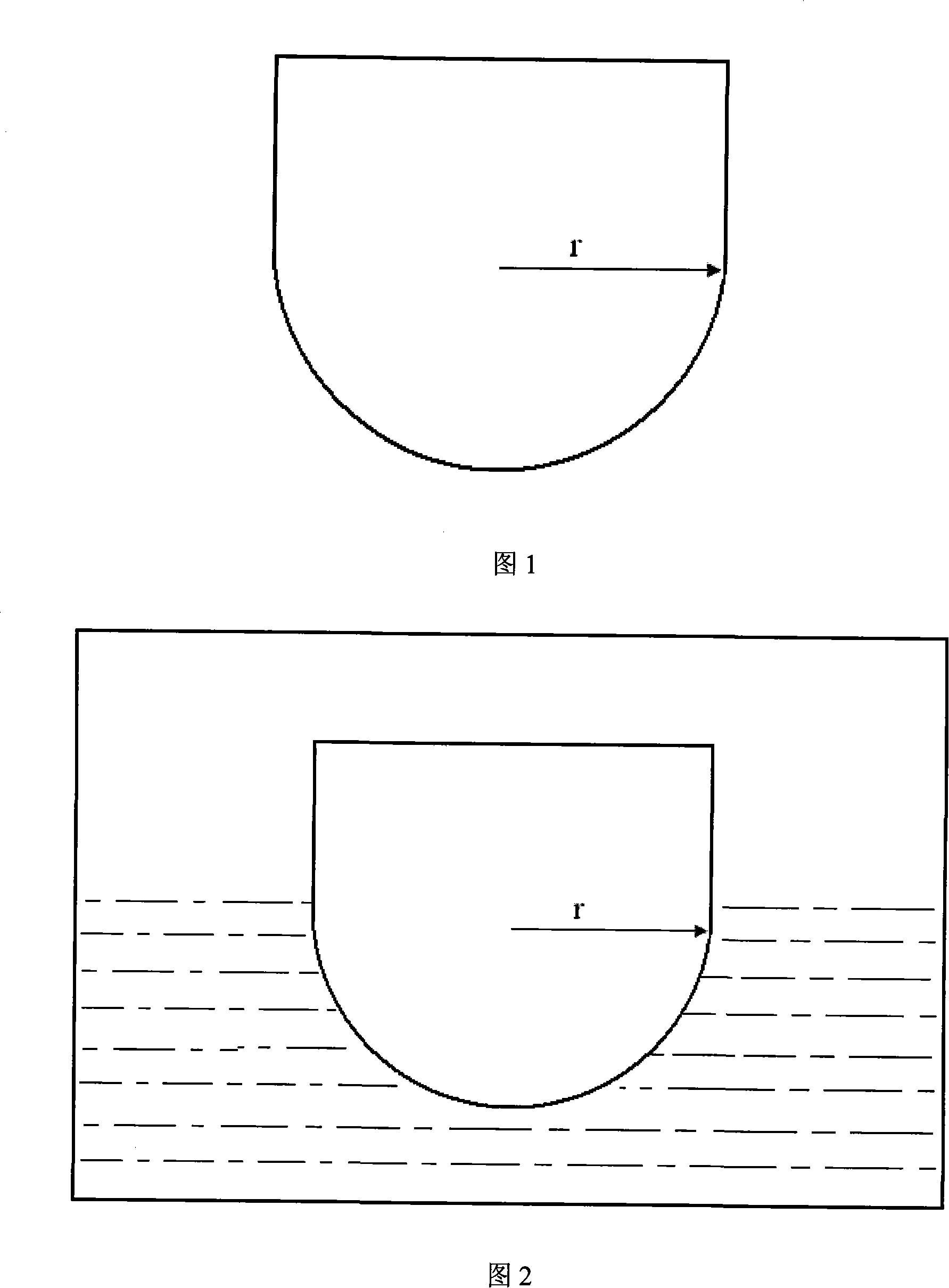

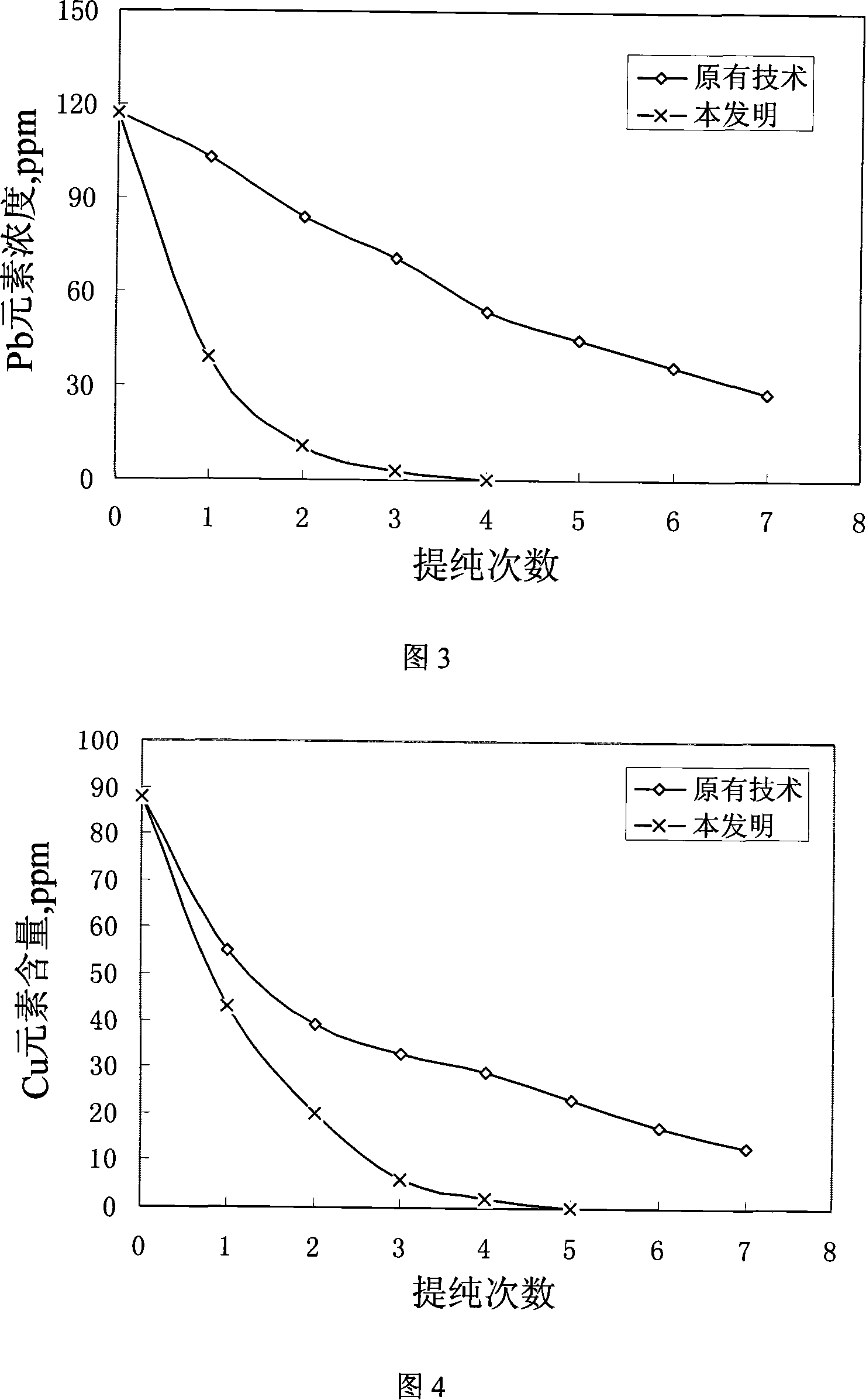

[0019] The invention provides a method for preparing high-purity gallium, comprising the following steps:

[0020] A. The clean and dry hemispherical reaction vessel is heated with a water bath at a temperature of 15°C to 25°C, and 5-10g of liquid high-purity gallium is evenly coated on the inner surface of the hemispherical reaction vessel to form a seed crystal, and the molten Thick gallium is added into the hemispherical reaction vessel, and the solidification speed of gallium is controlled to be 0.5cm 3 / min~1.5cm 3 / min, when the solidified gallium accounts for 60% to 90% of the total amount, the liquid gallium is poured out;

[0021] B. The solid gallium obtained in step A is used as a raw material, and step A is repeated;

[0022] Repeat steps A and B three to five times to obtain high-purity gallium as a product.

[0023] The diameter of the hemispherical reaction vessel is 50mm-120mm, the hemispherical part of the hemispherical reaction vessel needs to be completel...

Embodiment 1

[0026] A hemispherical reaction vessel with a diameter of 50 mm is washed with electronic grade deionized water and then dried; the vessel is placed in a water bath at 25°C, the hemispherical part is completely submerged in the water, and 5g of liquid high-purity gallium with a purity of 6N is coated on the inner surface of the vessel , after the seed crystal is formed, add molten crude gallium with a temperature of 30°C and a purity of 4N, adjust the temperature of the water bath to control the solidification speed of Ga to 0.8cm 3 / min, when the solidification amount reaches 80%, pour out the unsolidified liquid Ga, and use the obtained solid Ga as a raw material, repeat the above process 3 times, and obtain 6N high-purity gallium.

Embodiment 2

[0028] A hemispherical reaction vessel with a diameter of 80 mm is washed with electronic grade deionized water and then dried; the vessel is placed in a water bath at 24°C, the hemispherical part is completely submerged in the water, and 8 g of liquid high-purity gallium with a purity of 6N is coated on the inner surface of the vessel , after the seed crystal is formed, add molten gallium with a temperature of 30°C and a purity of 4N, adjust the temperature of the water bath to control the solidification speed of Ga to 0.6cm 3 / min, when the solidification amount reaches 80%, pour out the unsolidified liquid Ga, and use the obtained solid Ga as a raw material, repeat the above process 4 times, and obtain 6N high-purity gallium.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com