Minisize fluid forced convection device

A forced convection, miniature technology, used in sampling devices, liquid degassing, preparation of test samples, etc., can solve the problems of poor convection, complicated installation, damage, etc., and achieve the effect of reducing response time, simple structure and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

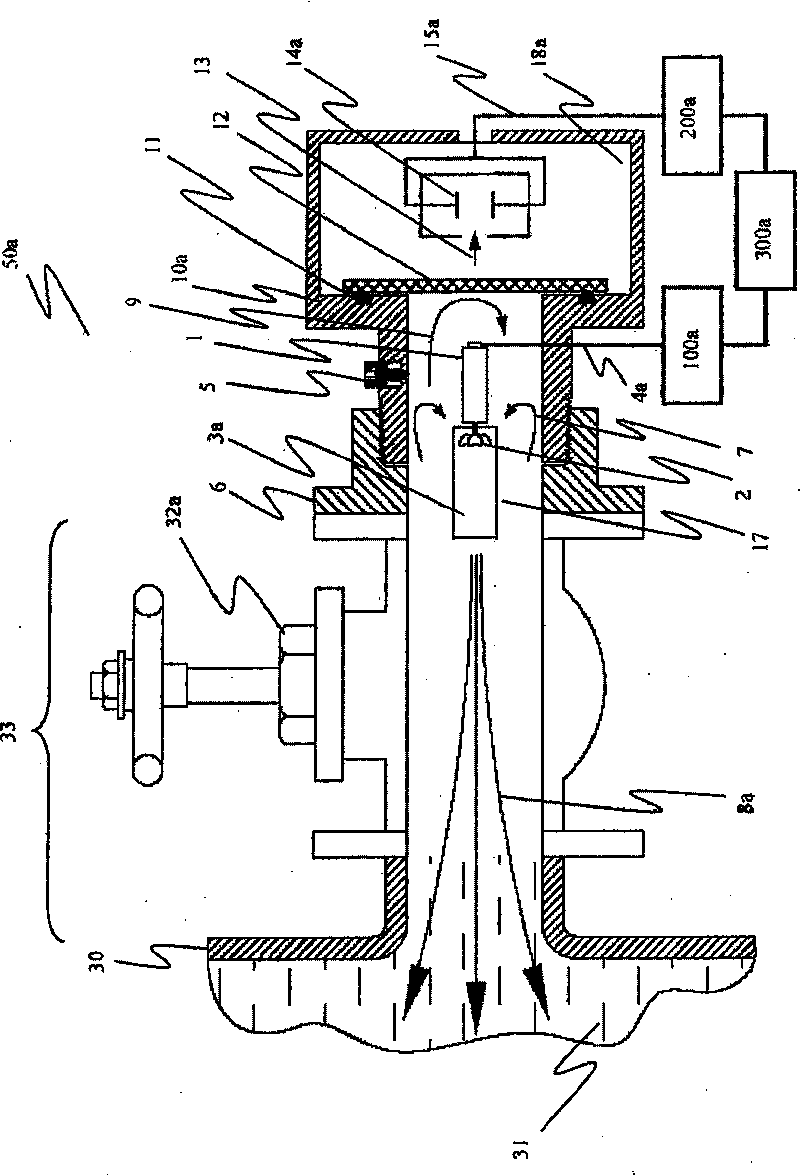

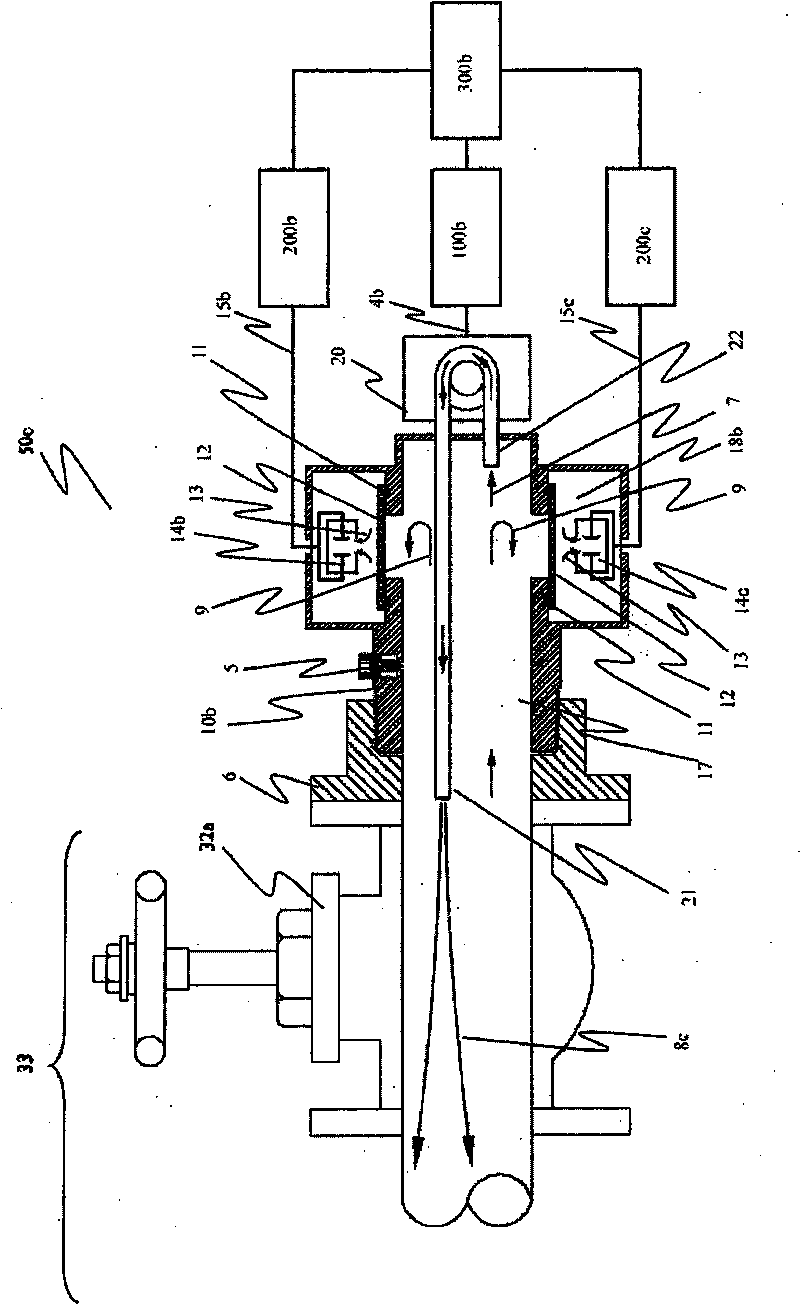

[0019] Such as Figure 1 to Figure 3 Shown are three preferred embodiments of the invention, in figure 1 with image 3 Among them, the straight-through valve 32a is installed in the transformer main oil tank 30 ( image 3 (not marked in), the total length of the oil pipe 33 between the main oil tank 30 and the valve 32a is greater than or equal to 6 times the inner diameter of the valve 32a, or the total length is greater than 200mm. When the valve 32a is fully opened, the transformer oil 31 in the main oil tank 30 can flow directly to the outside of the valve horizontally.

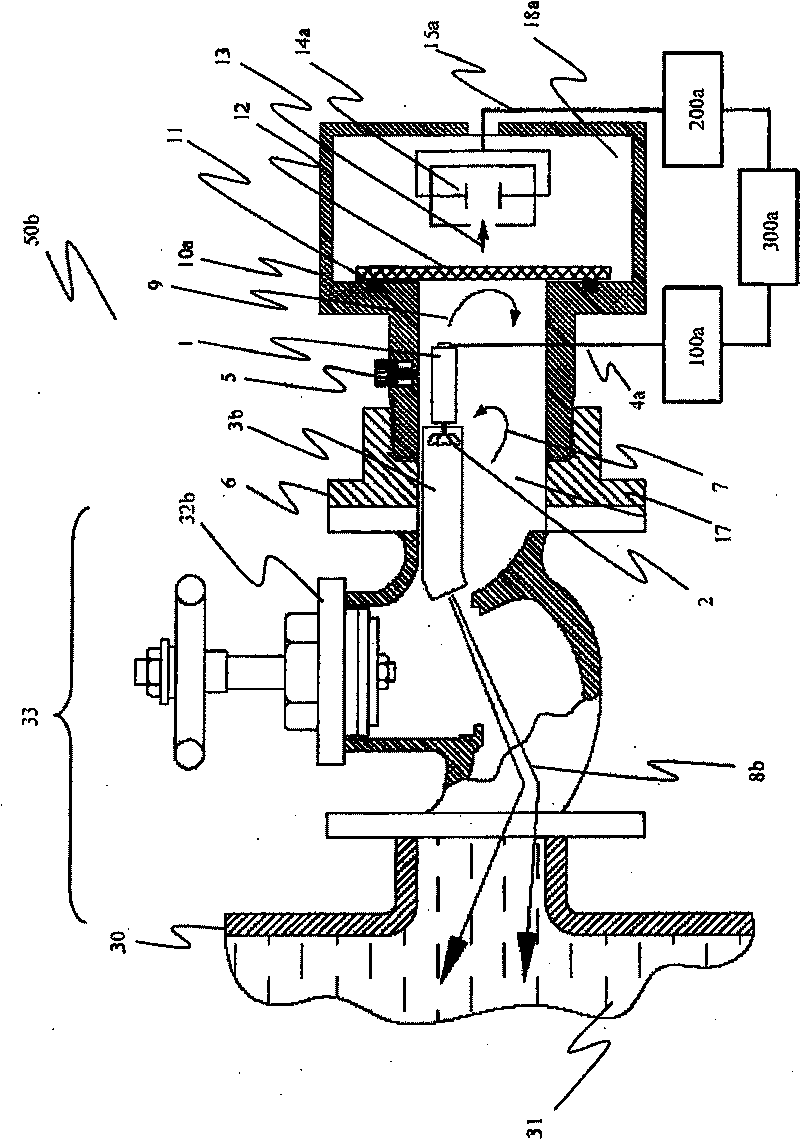

[0020] exist figure 2 Among them, the non-straight-through valve 32b is installed on the main oil tank 30 of the transformer. When the valve 32b is fully opened, the transformer oil 31 in the main oil tank 30 will communicate with the outside of the valve through a "Z" shaped channel.

[0021] from Figure 1 to Figure 3 It can be seen from the figure that the fluid forced convection devices 50a, 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com