Method and equipment for preparing gallium trichloride

A technology of gallium trichloride and gaseous gallium trichloride, applied in chemical instruments and methods, methods of chemically changing substances by using atmospheric pressure, pressure vessels used in chemical processes, etc., can solve the problem of low purity and high impurity content. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

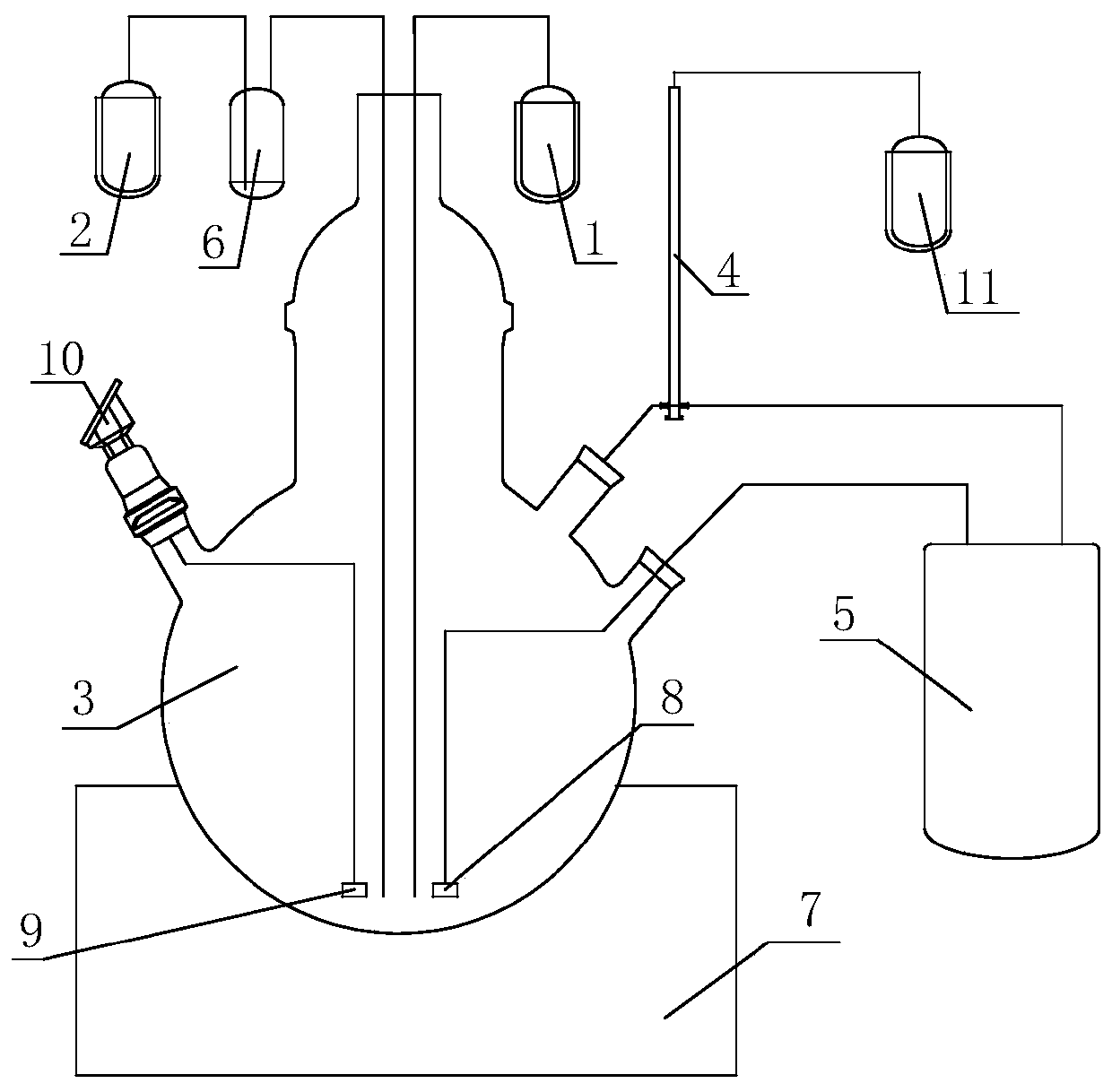

preparation example Construction

[0022] According to the first aspect of the present invention, a preparation method of gallium trichloride is provided, comprising the following steps: preheating the temperature of liquid metal gallium to 40-70°C, and preheating the initial temperature of the reaction vessel to 100-150°C First, liquid metal gallium is added to the reaction kettle, then chlorine gas after sulfuric acid drying is passed into the liquid metal gallium, and the chlorine gas is directly passed into the bottom of the metal gallium solution to ensure that the reaction can be completely complete; the synthesis reaction of the present invention consists of Two stages. In the first stage, the main product is gallium monochloride. By adjusting the temperature of the reactor, the temperature of the reactor is controlled at 200-400 ° C. After the first preset time period, the main product is gallium monochloride and gallium trichloride. Product, wherein, the gallium trichloride of by-product is liquid galli...

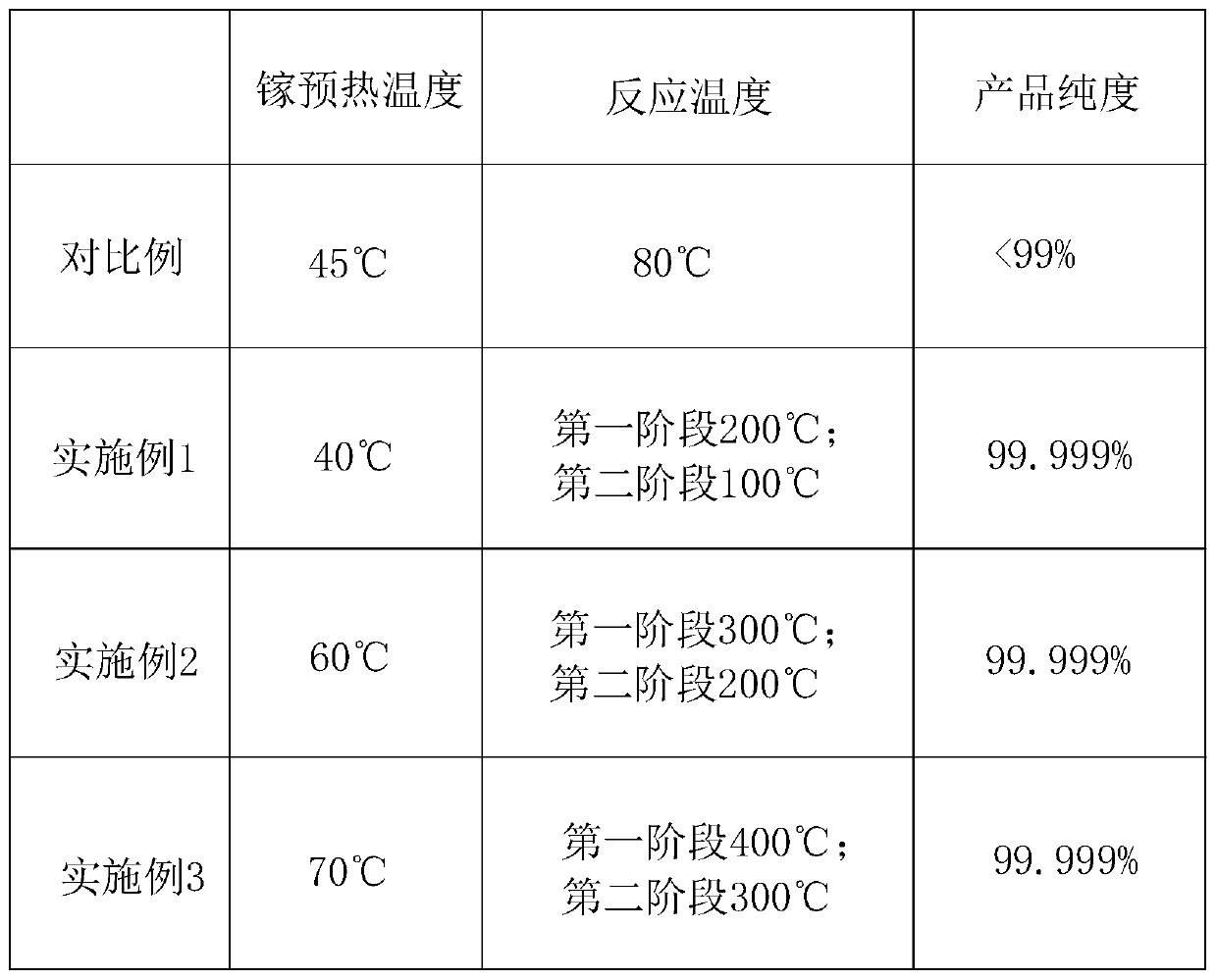

Embodiment 1

[0031] The gallium metal is preheated to 40°C, and the reactor is preheated to 100°C. Add liquid metal gallium into the reactor, pass chlorine gas into the bottom of the metal gallium liquid after being dried by sulfuric acid, control the reaction temperature at 200°C in the first stage of the reaction process, and control the reaction temperature at 100°C in the second stage, the reaction process The gallium trichloride in the medium is boiled and evaporated to the fractionating tube, and the fractionating tube cools the gaseous gallium trichloride to obtain liquid gallium trichloride which flows into the storage tank; after the reaction is complete, keep the reactor temperature at 150 ° C, and pass through the protective gas (It can be nitrogen or inert gas) to take away the chlorine gas dissolved in the gallium trichloride solution, and the purity of the dechlorinated gallium trichloride product can reach 99.999% after testing.

Embodiment 2

[0033]The difference from Example 1 is that the gallium metal is preheated to 60°C, the reactor is preheated to 120°C, the reaction temperature is controlled at 300°C in the first stage of the reaction process, and 200°C in the second stage, and the The temperature of the reactor is controlled at 200°C when the protective gas is used, and the purity of the dechlorinated gallium trichloride product can reach 99.999% after testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com