Zinc ion battery liquid metal composite negative electrode and preparation method and application thereof

A zinc-ion battery, liquid metal technology, applied in battery electrodes, electrolyte battery manufacturing, secondary batteries, etc., can solve problems such as capacity attenuation, eliminate dendrites, increase battery system interface impedance, achieve simple preparation process, avoid being Corrosion, the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Preparation of composite pole piece

[0040] Based on the composite pole piece of zinc metal matrix, its preparation method comprises the following steps:

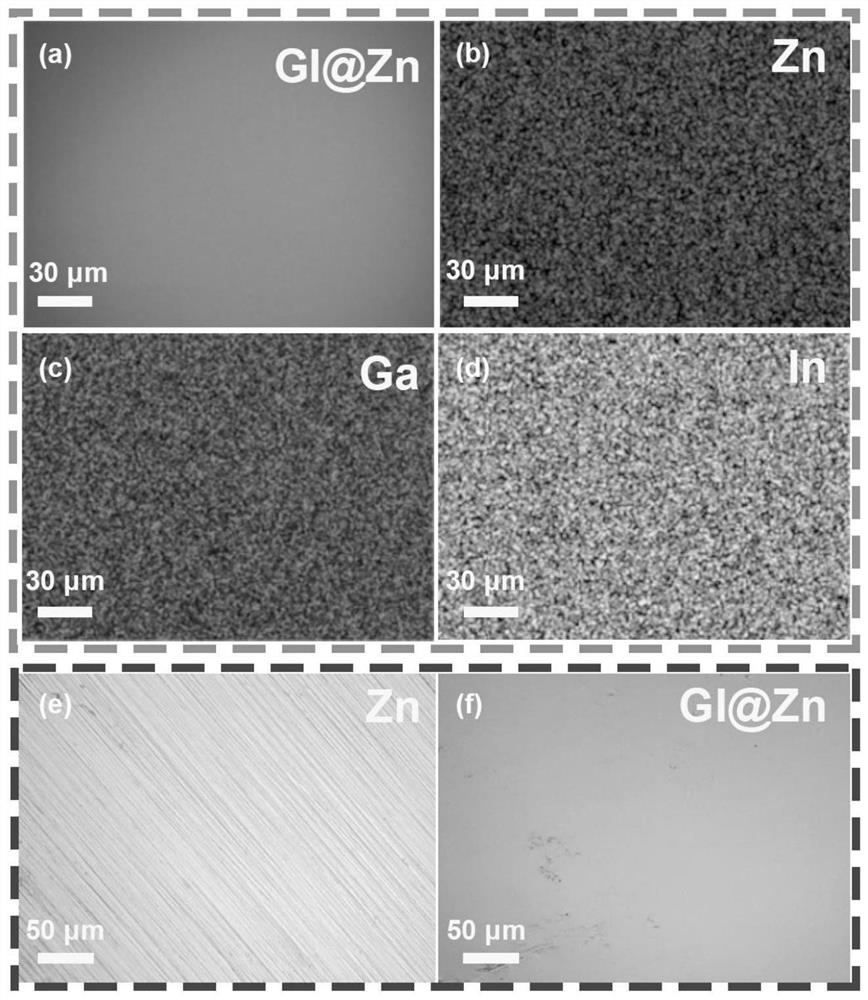

[0041] S1: Polish the surface of a commercial zinc foil with a thickness of 0.5mm (purity>99.999%) to remove the oxide layer with an electric grinder, and wash it alternately and repeatedly with distilled water and absolute ethanol to remove oxidized impurities on the surface of the zinc foil and increase the The roughness of the surface of the large zinc foil is cut into a diameter of 14mm and dried at room temperature for later use;

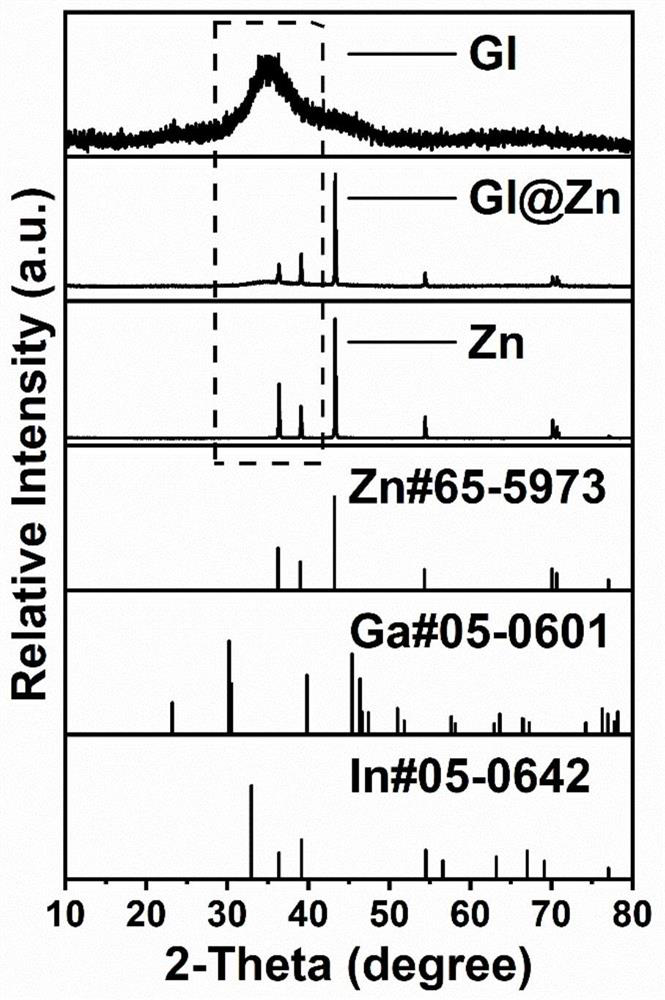

[0042] S2: At room temperature, use a pipette gun to pipette liquid gallium-indium alloy at room temperature, apply liquid gallium-indium alloy on the surface of zinc foil by mechanical scraping method, make the surface of zinc foil react with liquid gallium-indium alloy, and let it stand for 10 minutes Finally, wipe it clean so that the liquid gallium-indium alloy has a certain ...

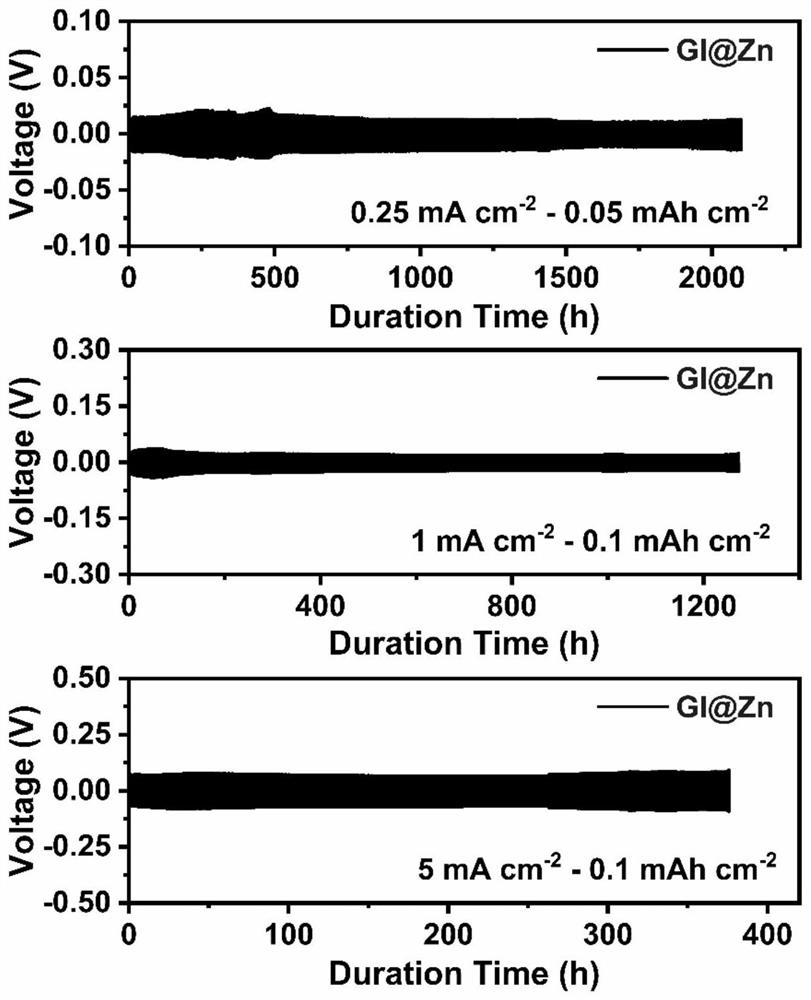

Embodiment 2-6

[0077] Examples 2-6 were respectively prepared according to the method of Example 1 based on the composite pole piece of zinc metal matrix and the CR2016 type button symmetrical battery was prepared respectively with the composite pole piece as the positive and negative electrodes. The difference between Examples 2-6 lies in the thickness of the zinc foil , gallium-indium alloy surface density on the surface of zinc foil and the time of standing during preparation are different, specifically as shown in Table 1; The test of the battery cycle performance, the test results are shown in Table 1:

[0078] Table 1 Preparation parameters of composite pole pieces and battery cycle performance test results of comparative examples 2-6

[0079]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com