Magnetic liquid metal printing ink and preparation method thereof

A technology of liquid metal and printing ink, which is applied in ink, household utensils, applications, etc., can solve the problems of high cost, poor material strength, and easy magnetization of ink materials, and achieve low cost, good formability, and improved printing and forming effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

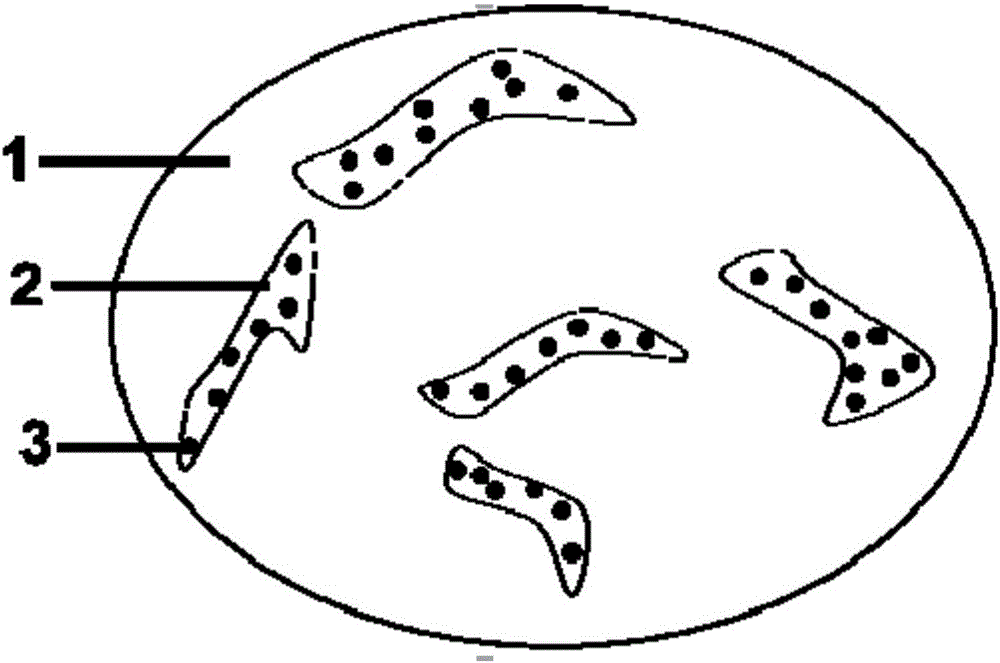

[0018] Such as figure 1 As shown, a magnetic liquid metal printing ink provided by the present invention is formed by uniformly mixing liquid metal 1 and magnetic liquid; wherein, liquid metal 1 is gallium and its binary and ternary alloys, preferably gallium indium di Elementary alloys, in parts by weight, the content of gallium is 30-90 parts, and the rest is indium; or gallium indium tin ternary alloy, in parts by weight, the content of gallium is 30-80 parts, and the content of indium is 10-20 parts parts, the rest is tin. In parts by weight, the liquid metal 1 content is 80-95 parts, and the magnetic liquid is a conventional magnetic liquid based on soft magnetic nano-magnetic particles 3, preferably water, organic solvent, oil, etc. as the base liquid 2, preferably with Oleic acid etc. are used as active agents to prevent agglomeration. The soft magnetic nano-magnetic particles 3 are nanoparticles of iron, cobalt, nickel and other ferromagnetic elements, preferably Fe,...

Embodiment 2

[0021] Such as figure 1 As shown, a magnetic liquid metal printing ink, which is uniformly mixed with liquid metal 1 gallium indium alloy and magnetic liquid, in parts by weight, the content of liquid metal 1 is 80 parts, and the content of gallium in liquid metal 1 is 80 parts , and the rest are indium. The magnetic liquid is prepared by mixing nano-Fe particles into deionized water and sodium oleate, wherein the content of nano-Fe particles is 5 parts.

Embodiment 3

[0023] Such as figure 1 As shown, a magnetic liquid metal printing ink is formed by mixing liquid metal 1 gallium indium alloy and magnetic liquid. In parts by weight, the content of liquid metal 1 is 85 parts, and the content of gallium in liquid metal 1 is 90 parts , and the rest are indium. The magnetic liquid is prepared by mixing kerosene and sodium oleate with nanometer Ni particles, wherein the content of nanometer Ni particles is 5 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com