Aluminum ion battery using liquid metal gallium as negative electrode

An aluminum-ion battery, liquid metal technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of unreusable aluminum negative electrodes, powdered negative electrodes, and waste of metal aluminum, so as to improve cycle stability and reduce waste. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

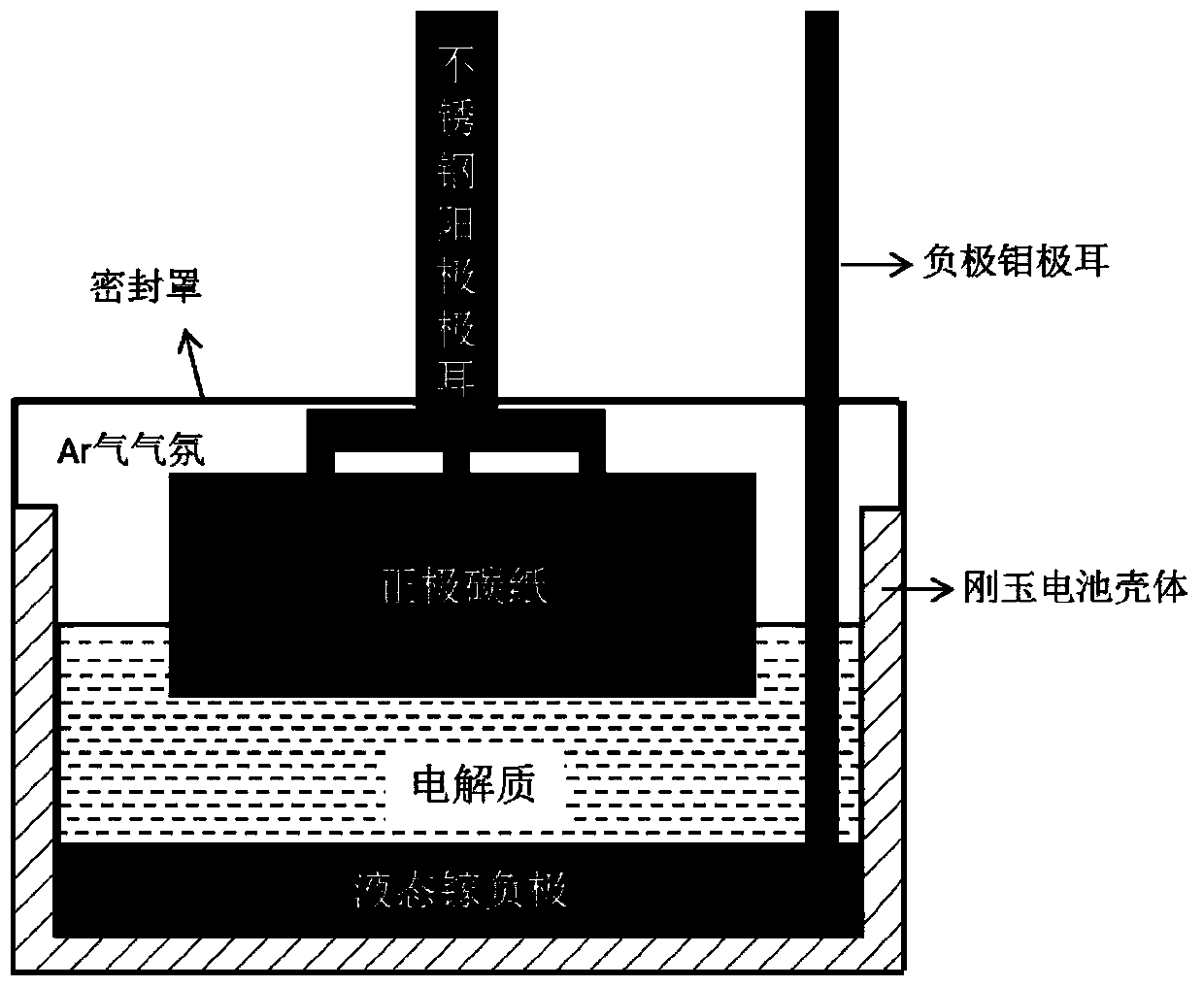

Embodiment 1

[0021] A corundum crucible was used as the battery case (inner diameter 100mm, height 100mm), liquid metal gallium was placed on the bottom layer of the corundum crucible (thickness 10mm), and metal molybdenum wire (diameter 1mm) was inserted into the liquid metal gallium as the negative electrode tab. Carbon paper is used as the positive electrode material, and the metal tantalum is used to connect the carbon paper as the positive electrode current collector; the carbon paper is wrapped with glass fiber as the positive electrode, and finally stainless steel is used to connect the metal tantalum as the positive electrode tab. Aluminum chloride and 1-ethyl-3-methylimidazolium chloride with a molar ratio of 1.3:1 were used as the electrolyte, which was placed on the upper layer of liquid gallium with a thickness of 10 mm. The entire battery is protected by inert argon gas and sealed to isolate oxygen and water. During the cycle of the battery, the positive electrode carbon paper...

Embodiment 2

[0023] A glass jar is used as the battery case (inner diameter 100mm, height 100mm), liquid metal gallium is placed on the bottom of the glass jar (thickness 10mm), and metal silver wire (diameter 1mm) is inserted into the liquid metal gallium as the negative electrode tab. Pyrolytic graphite is used as the positive electrode material, and metal molybdenum is used to connect the pyrolytic graphite as the positive electrode current collector; the pyrolytic graphite is coated with glass fiber as the positive electrode, and finally stainless steel is used to connect the metal molybdenum as the positive electrode tab. Aluminum chloride and sodium chloride with a molar ratio of 1.5:1 were used as the electrolyte, which was placed on the upper layer of liquid gallium with a thickness of 10 mm. The entire battery is protected by inert argon gas and sealed to isolate oxygen and water. The working temperature of the battery is 150±10°C. During the cycle of the battery, the positive ele...

Embodiment 3

[0025] Use a quartz tank as the battery case (inner diameter 100mm, height 100mm), put liquid metal gallium in a corundum crucible with holes in the side wall (inner diameter 10mm, side wall hole diameter 10mm), insert metal molybdenum wire (diameter 1mm) into the liquid metal The gallium is used as the negative tab. Nickel sulfide coated on tantalum foil is used as the positive electrode, and a stainless steel rod is connected as the positive electrode lug. A 1.6:1 ratio of aluminum chloride and 1-propyl-3-methylimidazole chloride was used as the electrolyte. The entire battery is protected by inert argon gas and sealed to isolate oxygen and water. During the cycle of the battery, the positive electrode carbon paper is immersed in the electrolyte, and the charge and discharge cycle is carried out in the potential range of 0.4-2.4V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com