High flow gaci3 delivery

A conveying pipeline, high-purity technology, applied in the field of conveying high-fluidity GaCl3, which can solve problems such as low flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

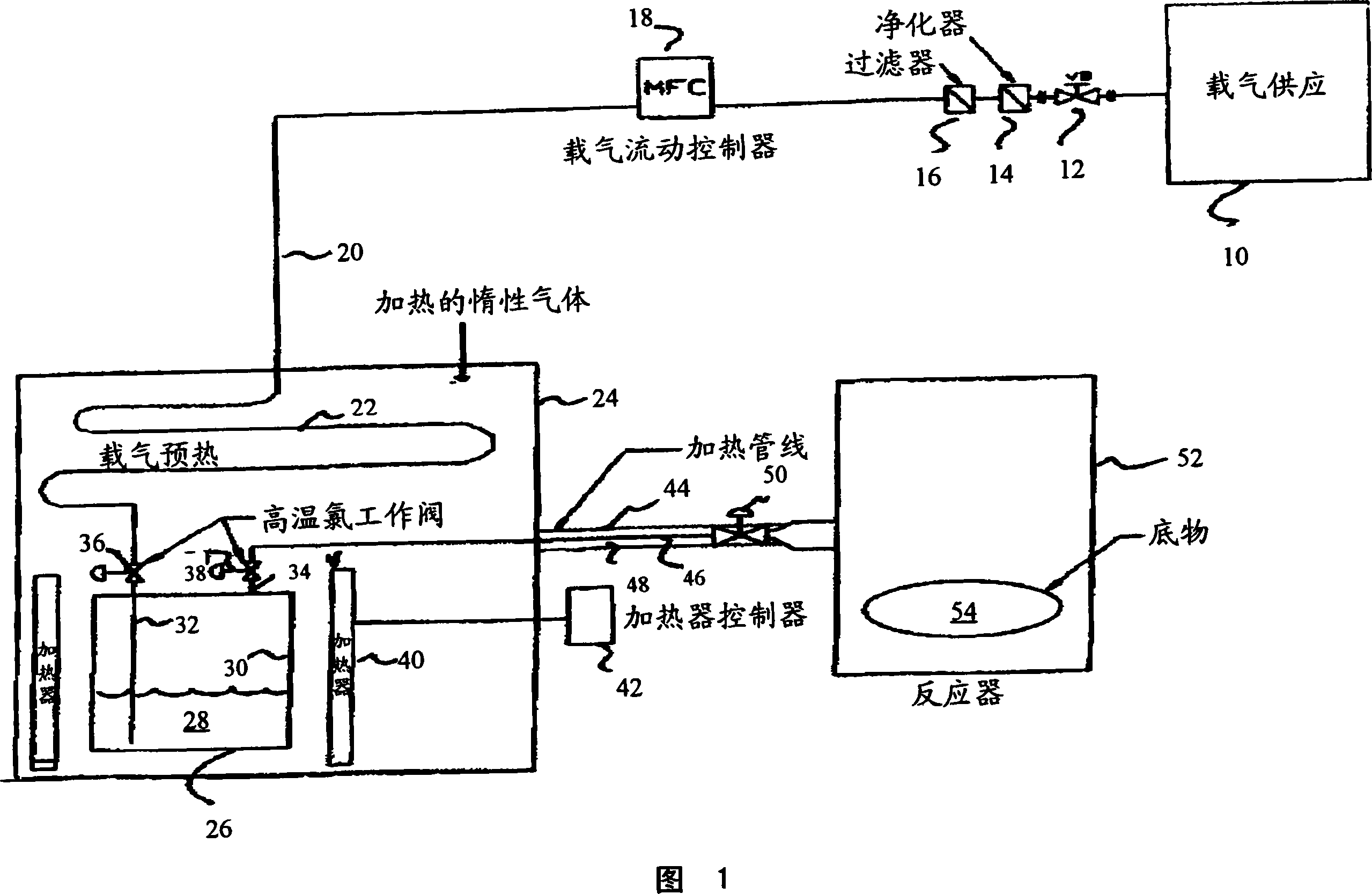

[0014] The apparatus and method of the present invention use high vapor pressure epitaxy (HVPE) in an epitaxial reactor by introducing high flow and high purity GaCl 3 Vapors are fed into the aforementioned reactors to enable chemical vapor deposition (CVD) for gallium film deposition.

[0015] Due to solid GaCl 3 The low vapor pressure, traditional gas phase delivery systems for solid precursors are not available for high flow and high purity GaCl 3 delivery.

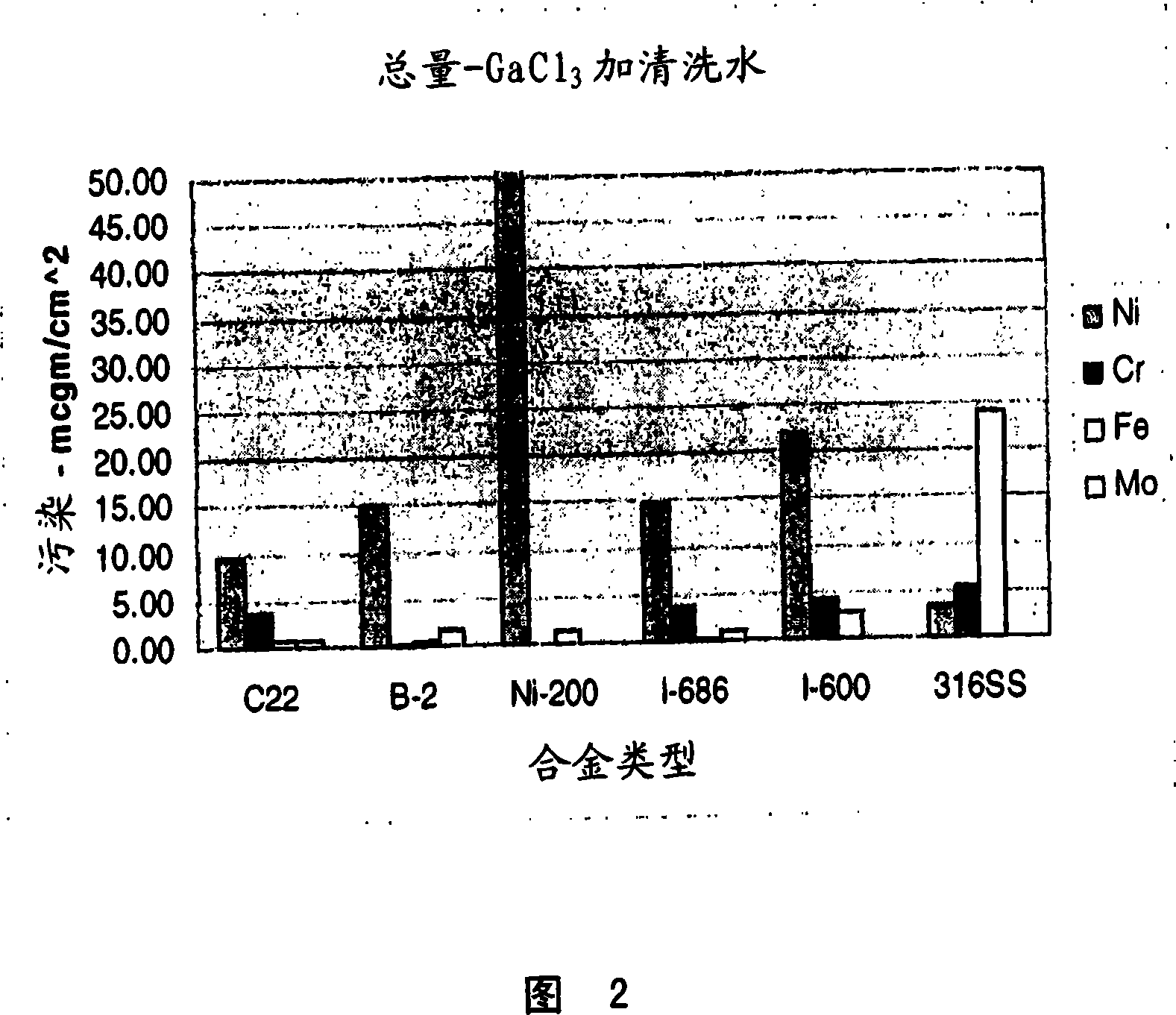

[0016] Existing liquid-phase gas-phase delivery systems that can deliver such high flow rates are not suitable for molten (greater than 80°C) due to their low temperature capabilities, and the chemical nature of chlorine accelerated at higher temperatures - highly corrosive GaCl 3 .

[0017] The present invention is described as follows. GaCl 3 The solid precursor was placed in a 316LSS bubbler vessel where it was heated above its 78°C melting point. At this temperature and above, it is liquid and can be foamed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com