Saturated solution for preparing electrothermal film and preparation method thereof

A technology of electric heating film and solution, applied in the direction of heating element materials, etc., can solve the problems of human body and operating environment, such as heat conversion efficiency, and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The invention provides a saturated solution for preparing an electrothermal film, which is composed of tin tetrachloride, titanium tetrachloride, cobalt trichloride, gallium trichloride and ethylene glycol, first adding 30% tin tetrachloride Stir in the ethylene glycol to dissolve completely, then add titanium tetrachloride, cobalt trichloride and gallium trichloride to the remaining 70% ethylene glycol in sequence, stir to dissolve completely, and finally mix and stir the two solutions evenly. The mass percentage of the described tin tetrachloride in the saturated solution is 30%, the mass percentage of the described titanium tetrachloride in the saturated solution is 20%, the mass percentage of the described cobalt trichloride in the saturated solution The mass percentage of the gallium trichloride in the saturated solution is 10%, and the mass percentage of the ethylene glycol in the saturated solution is 20%.

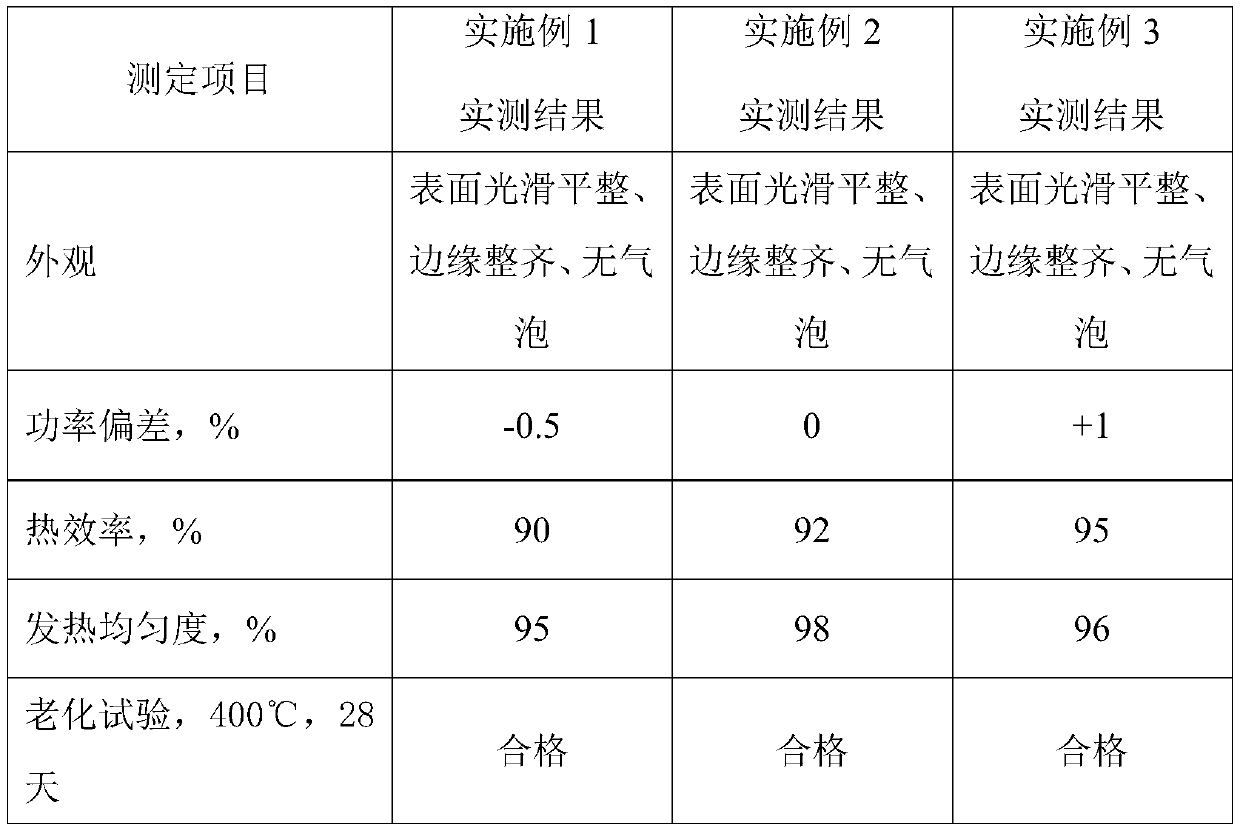

[0018] The physical and chemical indicators are shown i...

Embodiment 2

[0020] The invention provides a saturated solution for preparing an electrothermal film, which is composed of tin tetrachloride, titanium tetrachloride, cobalt trichloride, gallium trichloride and ethylene glycol, first adding 40% tin tetrachloride Stir in the ethylene glycol to dissolve completely, then add titanium tetrachloride, cobalt trichloride and gallium trichloride to the remaining 60% ethylene glycol in sequence, stir to dissolve completely, and finally mix and stir the two solutions evenly. The mass percent of described tin tetrachloride in saturated solution is 35%, the mass percent of described titanium tetrachloride in saturated solution is 15%, the mass percent of described cobalt trichloride in saturated solution is 10%, the mass percentage of the gallium trichloride in the saturated solution is 10%, and the mass percentage of the ethylene glycol in the saturated solution is 30%.

[0021] The physical and chemical indicators are shown in Table 1.

Embodiment 3

[0023] The invention provides a saturated solution for preparing an electrothermal film, which is composed of tin tetrachloride, titanium tetrachloride, cobalt trichloride, gallium trichloride and ethylene glycol, first adding 50% tin tetrachloride Stir in ethylene glycol to dissolve completely, then add titanium tetrachloride, cobalt trichloride and gallium trichloride to another 50% ethylene glycol in turn, stir to dissolve completely, and finally mix the two solutions evenly . The mass percentage of described tin tetrachloride in saturated solution is 40%, the mass percentage of described titanium tetrachloride in saturated solution is 10%, the mass percentage of described cobalt trichloride in saturated solution is 10%, the mass percentage of the gallium trichloride in the saturated solution is 20%, and the mass percentage of the ethylene glycol in the saturated solution is 20%.

[0024] The physical and chemical indicators are shown in Table 1.

[0025] Table 1

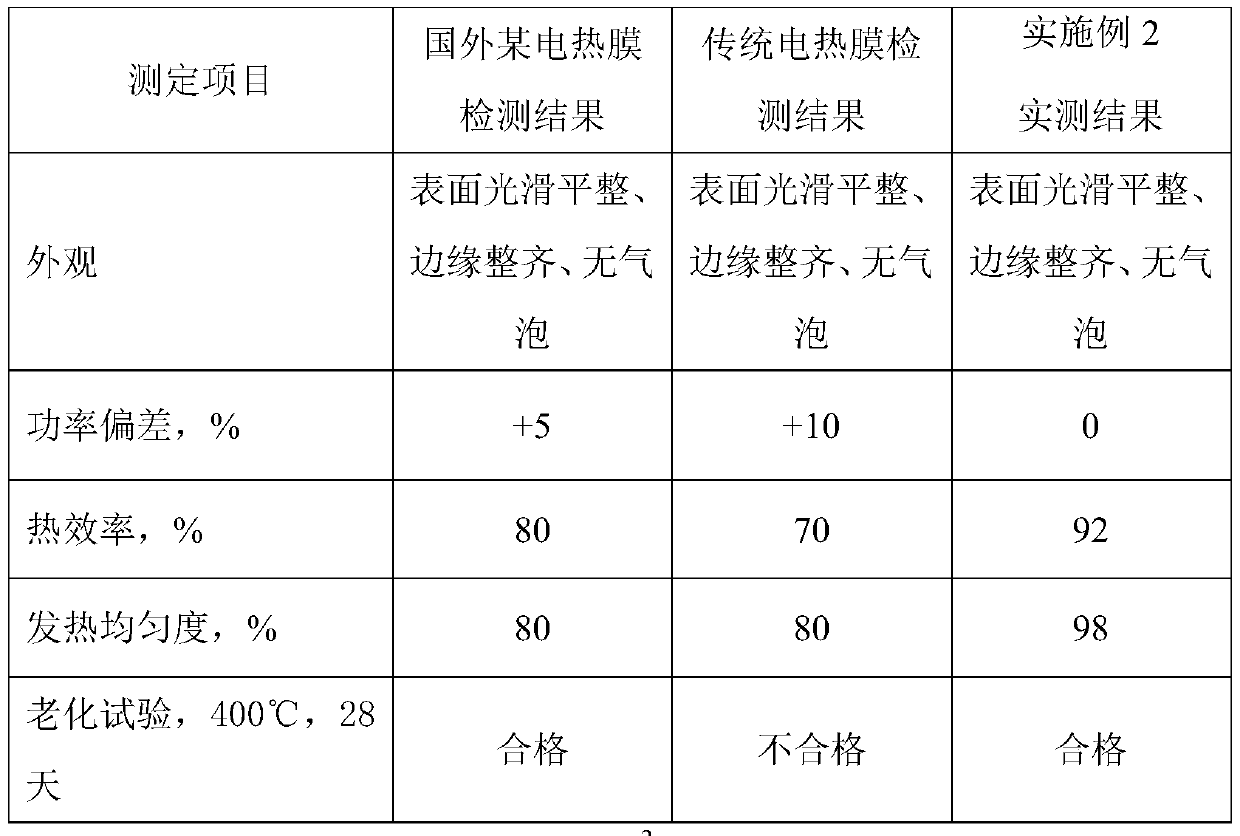

[0026...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com