Preparation method of gallium oxide hydroxide nano-crystals

A technology of gallium oxyhydroxide and nanocrystals, which is applied in the field of preparation of IIIA group oxyhydroxide nanomaterials, can solve the problems of GaOOH preparation work without efficient progress, harsh conditions, and low sample yield, achieving low cost and inhibited reaction The effect of speed and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

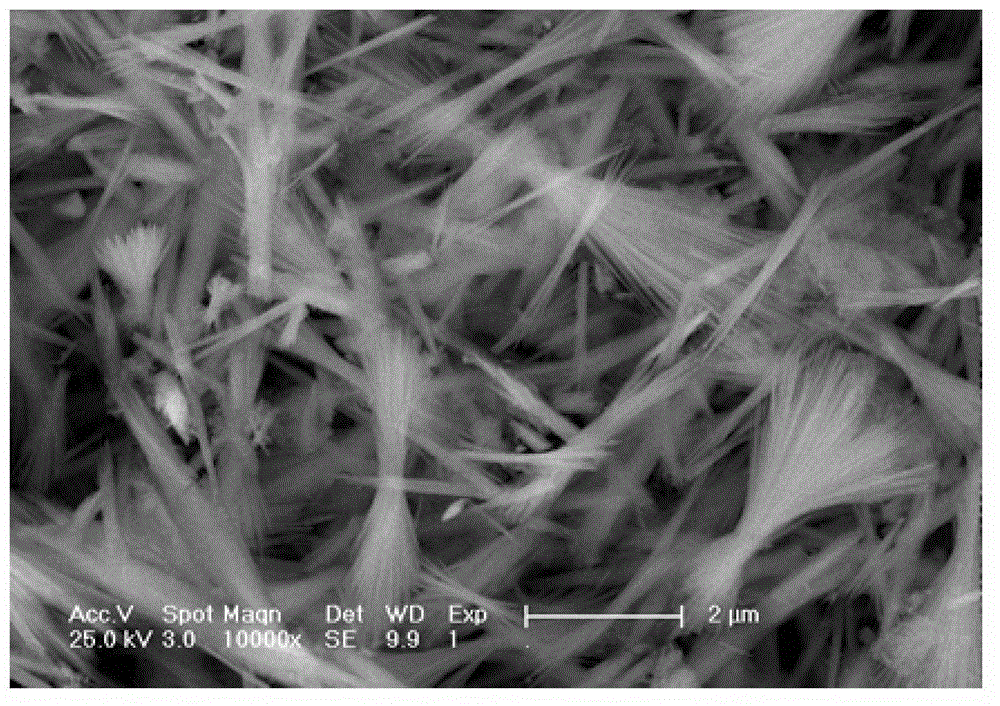

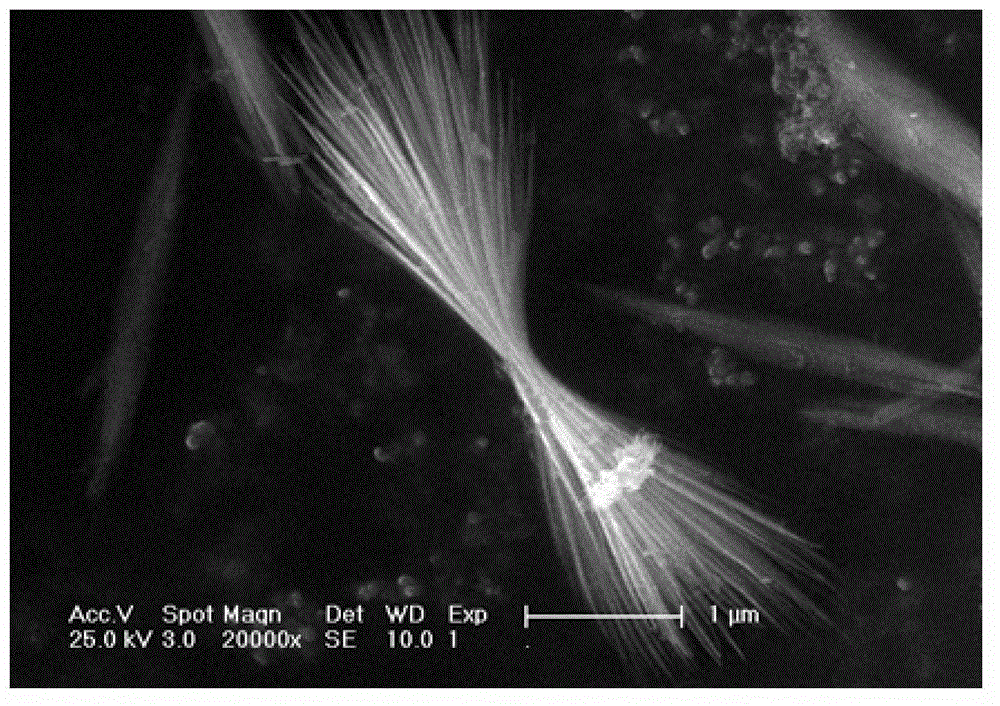

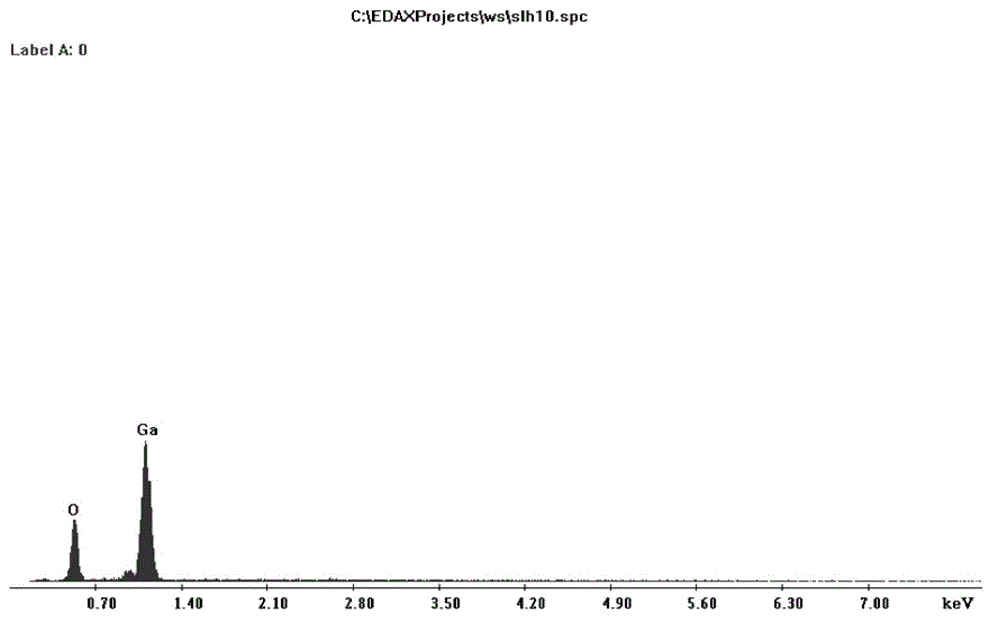

[0027] Embodiment 1 The whole process of preparing the best GaOOH nano brush.

[0028] Using high-purity gallium chloride, benzene, and methanol as raw materials, first dissolve gallium chloride in benzene to prepare a benzene-saturated solution of gallium chloride. Use a pipette to measure 1.5ml of the benzene saturated solution of gallium chloride prepared in advance and put it into a clean beaker, dilute it to 12ml with benzene to obtain the dilution. Afterwards, the beaker was placed in an ultrasonic instrument for ultrasonic treatment, and methanol was dropped into the diluent with a syringe at the same time during the ultrasonic treatment. Stop ultrasound when 25ml of methanol is added (dropping time is about 2 hours), take out the beaker, pour the liquid in the beaker into a self-made (40ml) polytetrafluoroethylene reaction kettle, seal and heat at 160°C for 48h. After the reaction, when the temperature of the reaction kettle dropped to room temperature, the liquid in ...

Embodiment 2

[0030]Example 2 The whole process of preparing GaOOH nanocrystals.

[0031] Using high-purity gallium chloride, benzene, and methanol as raw materials, first dissolve gallium chloride in benzene to prepare a benzene-saturated solution of gallium chloride. Use a pipette to measure 1.5ml of the benzene saturated solution of gallium chloride prepared in advance and put it into a clean beaker, dilute it to 12ml with benzene to obtain the dilution. Afterwards, the beaker was placed in an ultrasonic instrument for ultrasonication, and methanol was dropped into the diluent dropwise with a syringe at the same time during the ultrasonication process. Stop ultrasound when 25ml of methanol is added (dropping time is about 2 hours), take out the beaker, pour the liquid in the beaker into a self-made (40ml) Teflon reaction kettle, seal and heat at 160°C for 12h. After the reaction, when the temperature of the reaction kettle dropped to room temperature, the liquid in the kettle was taken ...

Embodiment 3

[0033] Example 3 The whole process of preparing GaOOH nanocrystals.

[0034] Using high-purity gallium chloride, benzene, and methanol as raw materials, first dissolve gallium chloride in benzene to prepare a benzene-saturated solution of gallium chloride. Use a pipette to measure 1.5ml of the benzene saturated solution of gallium chloride prepared in advance and put it into a clean beaker, dilute it to 12ml with benzene to obtain the dilution. Afterwards, the beaker was placed in an ultrasonic instrument for ultrasonication, and methanol was dropped into the diluent dropwise with a syringe at the same time during the ultrasonication process. Stop ultrasound when 25ml of methanol is added (dropping time is about 1.5 hours), take out the beaker, pour the liquid in the beaker into a self-made (40ml) Teflon reaction kettle, seal and heat at 180°C for 12h. After the reaction, when the temperature of the reaction kettle dropped to room temperature, the liquid in the kettle was tak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com