Saturated solution used to prepare electrothermal film

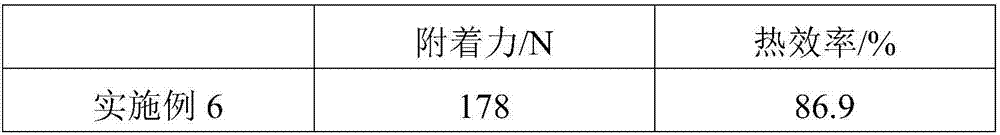

An electrothermal film and solution technology, applied in the field of saturated solution, can solve the problems of peeling off, insufficient stability and poor adhesion of the electrothermal film coating, and achieve the effects of stable work, long service life and high thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Electrothermal film solution raw materials (parts by weight): 48 parts of tin tetrachloride, 5 parts of titanium tetrachloride, 4 parts of nickel tetrachloride, 3 parts of zinc acetate, 3 parts of gallium trichloride, 5 parts of hydrochloric acid, 3 parts of isopropanol Parts, 28 parts of absolute ethanol.

[0031] The specific preparation steps of the electrothermal film are as follows:

[0032] (1) Configure the electrothermal film treatment solution: weigh each raw material by weight, place it in a high-speed mixing heater, heat it to 60°C, stir at a speed of 600 rpm for 4 hours, mix and stir evenly, and make the solid All dissolved, cooled to room temperature, filtered with 100-mesh filter cloth to obtain electrothermal membrane treatment solution;

[0033] (2) First wash the surface of the quartz glass with distilled water to remove the dust on the surface of the quartz glass, then put it into an ultrasonic cleaner and use ethanol to sonicate for 30 minutes. The u...

Embodiment 2

[0038] It is basically the same as Example 1, the only difference is:

[0039] Electrothermal film solution raw materials (parts by weight): 48 parts of tin tetrachloride, 5 parts of titanium tetrachloride, 4 parts of nickel tetrachloride, 3 parts of zinc acetate, 3 parts of gallium trichloride, 5 parts of hydrochloric acid, 3 parts of isopropanol parts, 4 parts of hydrogen peroxide, and 28 parts of absolute ethanol.

Embodiment 3

[0041] It is basically the same as Example 1, the only difference is:

[0042] Electrothermal film solution raw materials (parts by weight): 48 parts of tin tetrachloride, 5 parts of titanium tetrachloride, 4 parts of nickel tetrachloride, 3 parts of zinc acetate, 3 parts of gallium trichloride, 5 parts of glacial acetic acid, isopropanol 3 parts, 4 parts of hydrogen peroxide, 28 parts of absolute ethanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com