Method for preparing Keggin polycation chloride crystal

A chloride, polyaluminum chloride technology, applied in chemical instruments and methods, crystal growth, single crystal growth and other directions, can solve the problems of difficult preparation of Keggin structure polycationic chloride crystals, and achieve the effect of simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) PAC solid-phase synthesis reaction: at 80℃, slowly melt 3.7g aluminum powder into 87ml C=5mol / lAlCl 3 In the solution, make the degree of alkalinity 0.8. After all the aluminum powder has reacted, filter the solution and evaporate at room temperature. The obtained solid is washed with isopropanol to obtain the PAC solid, which is dried in an oven for use.

[0031] (2) Keggin-GaAl 12 Chloride synthesis reaction: Dissolve 4.5g of the above PAC solid in 25ml methanol, sonicate in an ultrasonic instrument for about 10 minutes, after all the solids are dissolved, the solid GaCl 3 Dissolve in the solution, make n(Al) / n(Ga)=1.6, evaporate and crystallize at room temperature. Get pure Keggin-GaAl in 15 days 12 Chloride crystals.

Embodiment 2

[0033] (1) PAC solid-phase synthesis reaction: 2.6g of pure Al(OH) 3 Slowly dissolve in 12ml C=5.1mol / l HCl solution. After all is dissolved, add 50ml water to make the alkalinity 1.2. At 80°C, after all the solids have reacted, the solution is filtered and evaporated at room temperature. The obtained solid is washed with isopropanol to obtain PAC solid, which is dried in an oven for use.

[0034] (2) Keggin-GaAl 12 Chloride synthesis reaction: Dissolve 4.5g PAC solid in 25ml methanol, sonicate in an ultrasonic instrument for about 10 minutes, after the solids are all dissolved, remove the solid GaCl 3 Dissolve in the solution, make n(Al) / n(Ga)=6.4, evaporate and crystallize at room temperature. Get pure Keggin-GaAl in 15 days 12 Chloride crystals.

Embodiment 3

[0036] (1) PAC solid-phase synthesis reaction: at 80℃, slowly add 19.3g aluminum powder to 103ml C=5.3mol / lAlCl 3 In the solution, make the degree of alkalinity 1.3. After all the aluminum powder has reacted, filter the solution and evaporate at room temperature. The obtained solid is washed with isopropanol to obtain PAC solid, which is dried in an oven for use.

[0037] (2) Keggin-GaAl 12 Chloride synthesis reaction: Dissolve 4.5g PAC solids in 25ml methanol, sonicate them in an ultrasonic instrument for about 10 minutes, after all the solids are dissolved, add solid GaCl 3 Dissolve in the solution, make n(Al) / n(Ga)=26, evaporate and crystallize at room temperature. Get pure Keggin-GaAl in 15 days 12 Chloride crystals.

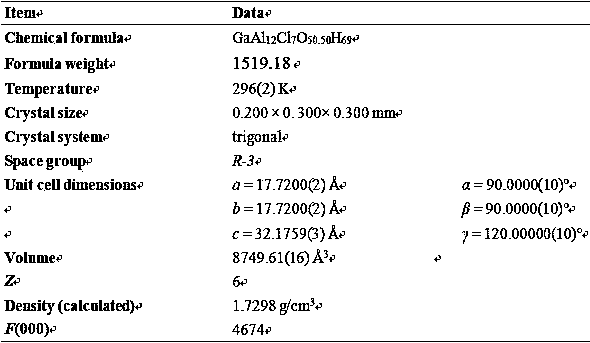

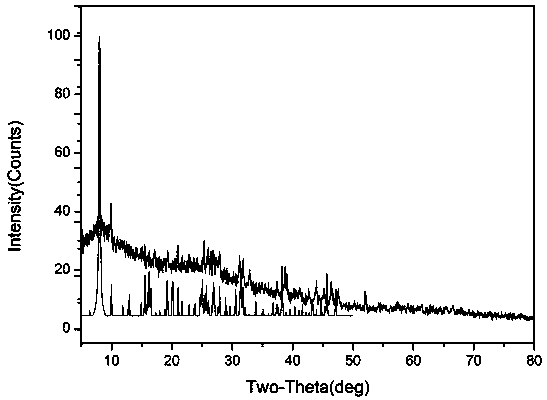

[0038] In the above cases, single crystal particles with a size of about 3mm and polycrystalline powders can be obtained. The analysis results are shown in the attachment figure 1 , 2, 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com