Trimethylchloroethylamine-containing multipolar axis plastic ferroelectric and piezoelectric material as well as preparation and application thereof

A technology of trimethylchloroethylamine and piezoelectric materials, which is applied in the growth of polycrystalline materials, the preparation of amino compounds, the preparation of organic compounds, etc., can solve problems such as limited application and performance limitations, and achieve excellent piezoelectric properties, Simple preparation method and high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

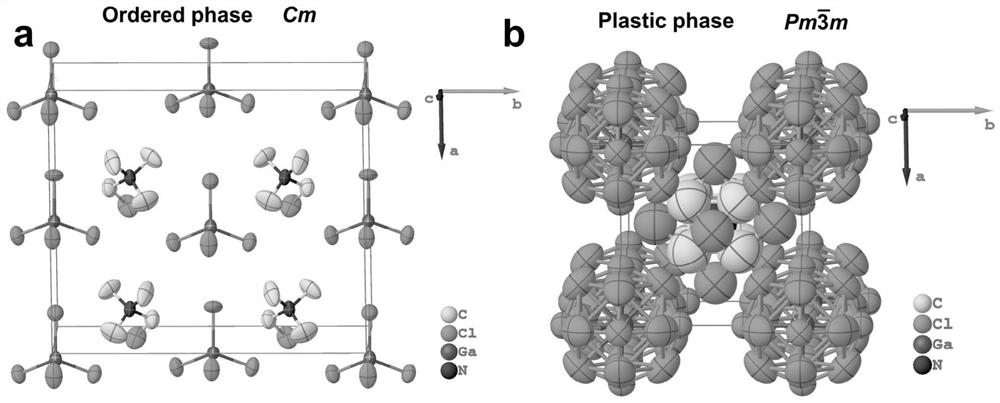

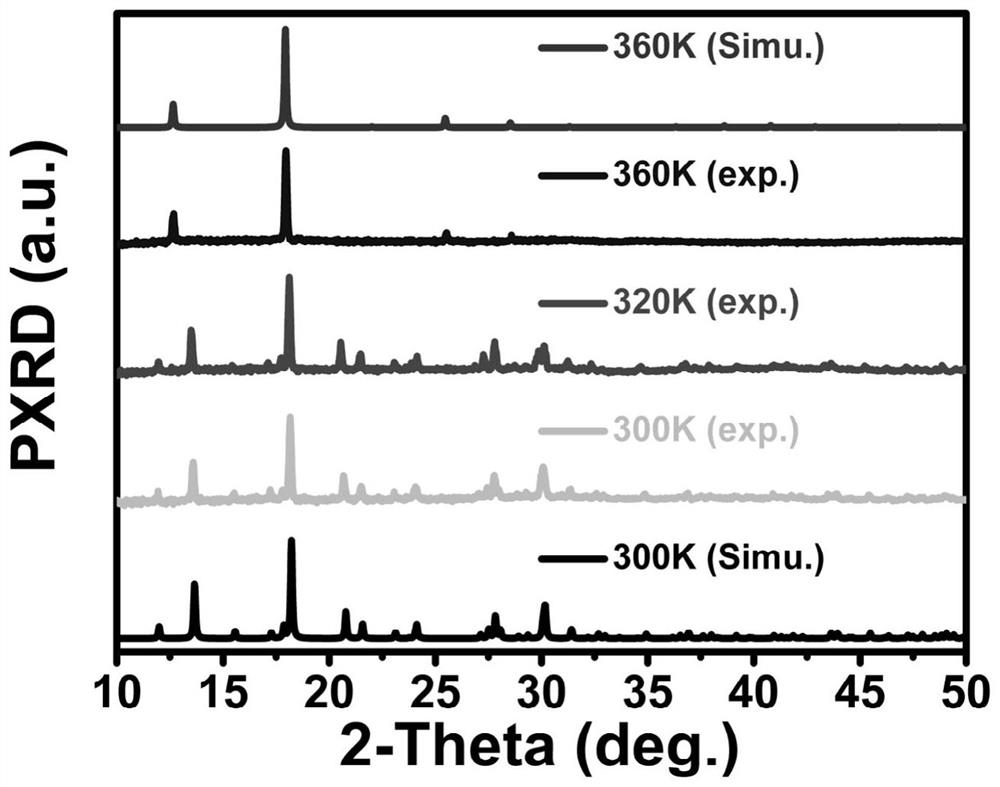

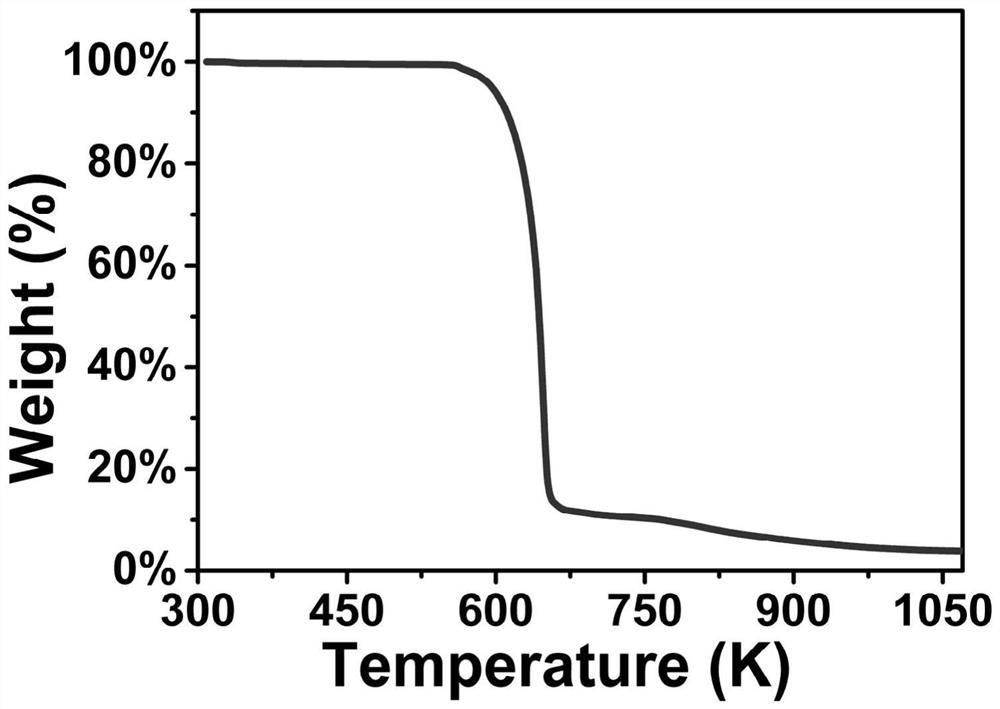

Method used

Image

Examples

Embodiment 1

[0025] The preparation process of multipolar axially plastic ferroelectric and piezoelectric materials containing trimethylchloroethylamine: mix 5mmol trimethylchloroethylammonium chloride with 10mL deionized water, and add 5mmol trichloride while stirring gallium. The mixed solution was stirred for 20 minutes, filtered to obtain a clear solution, volatile and grown at normal temperature and pressure, and colorless transparent crystals were obtained after standing for 3 to 7 days.

Embodiment 2

[0027] The preparation process of multipolar axially plastic ferroelectric and piezoelectric materials containing trimethylchloroethylamine: mix 5mmol trimethylchloroethylammonium chloride with 20mL of ethanol, and add 5mmol of gallium trichloride while stirring . The mixed solution was stirred for 50 min, filtered to obtain a clear solution, and volatilized and grown at normal temperature and pressure. After standing for 3 days, a colorless transparent crystal was obtained.

Embodiment 3

[0029] The preparation process of multipolar axially plastic ferroelectric and piezoelectric materials containing trimethylchloroethylamine: mix 5mmol trimethylchloroethylammonium chloride with 15mL of deionized water, and add 6mmol trichlorohydrin while stirring gallium chloride. The mixed solution was stirred for 60 min, filtered to obtain a clear solution, volatile and grown at normal temperature and pressure, and colorless transparent crystals were obtained after standing for 1 day.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com