Desulfurization system pH value control system and method based on predictive control

A predictive control and desulfurization system technology, applied in general control systems, control/regulation systems, adaptive control, etc., can solve the problems of reducing the quality of desulfurization by-products, lagging automatic pH value control, frequent load changes and large changes, etc. Achieve the effects of improving pH value tracking ability and anti-disturbance ability, advanced control with short callback time, and easy engineering implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

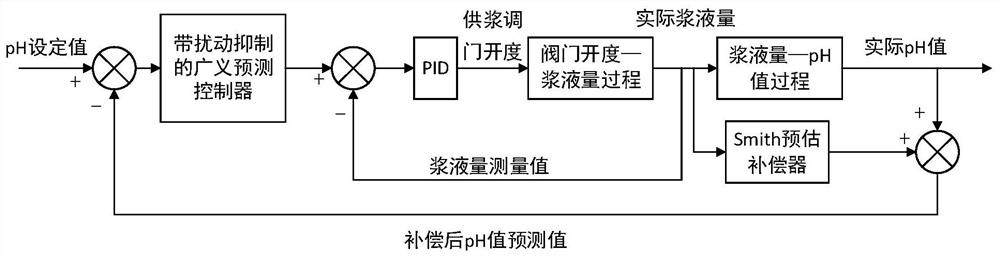

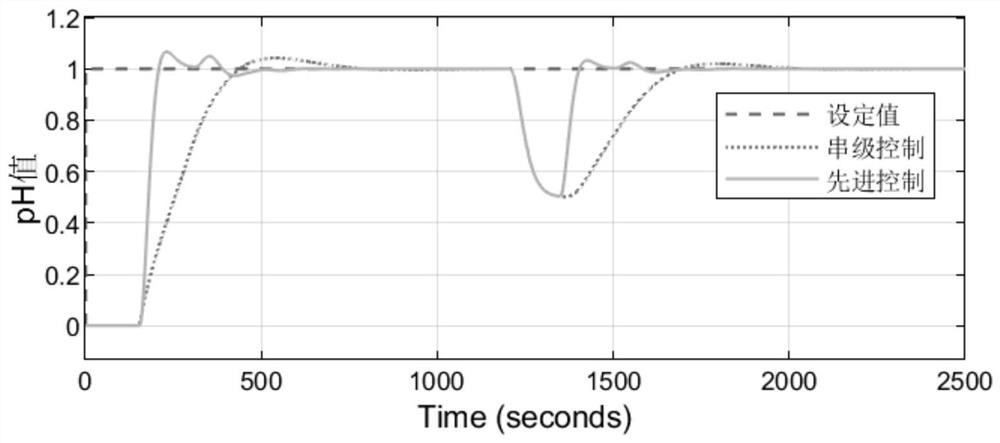

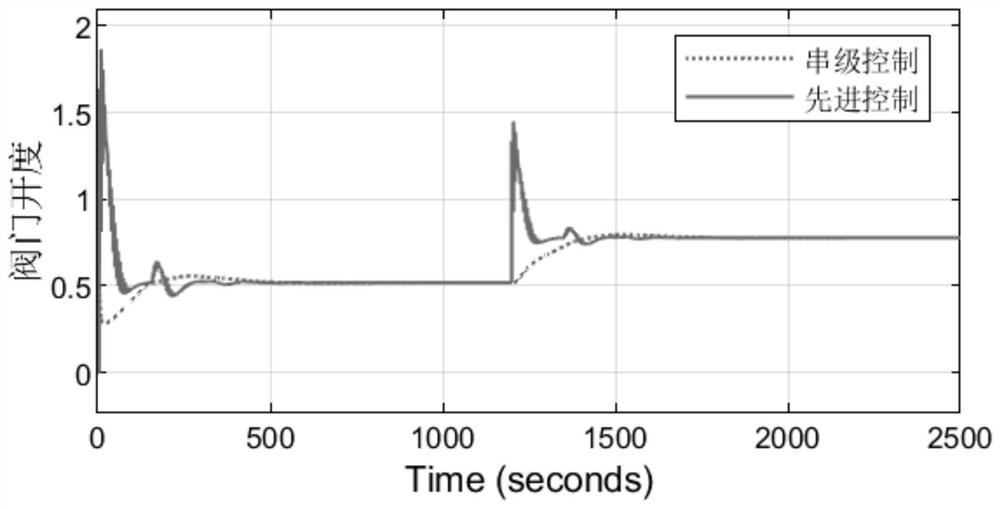

[0054] A method for controlling the pH value of a desulfurization system based on predictive control. The basic control calculation framework of generalized predictive control includes: obtaining a pH set value, and processing the pH set value based on a generalized predictive control model with disturbance control; The result is rolling optimization; based on the optimization result, feedback correction is made to the pH setting value. The general generalized predictive control only uses the dynamic model of the control variable and the adjusted variable as the internal predictive model of the predictive control, the measurable disturbance and the relationship between the control variable and the regulated variable are jointly modeled, and the dynamic model with the measurable disturbance is used as The internal model of generalized predictive control is generalized predictive control with disturbance suppression. For predictive control itself, no matter how the internal mode...

Embodiment 2

[0095] A pH value control system for desulfurization system based on predictive control, comprising:

[0096] Acquisition module, used for obtaining PH setting value;

[0097] The model processing module is used to process the PH setpoint based on the generalized predictive control model with disturbance control;

[0098] An optimization module is used for rolling optimization based on processing results;

[0099] The correction module is used for performing feedback correction on the pH setting value based on the optimization result.

[0100] Among them, the generalized predictive control model with disturbance control is:

[0101]

[0102] in, is the predicted estimated value of j-step sampling based on the known measurement information at time t, Δu(t+j-1) is the future control quantity increment vector that needs to be optimized and calculated for the control objective function, Δ=1- z -1 For difference operation, N 1 with N 2 are the start time and final end ti...

Embodiment 3

[0114] The embodiment of the present invention also provides a predictive control-based pH control device for a desulfurization system, including a processor and a storage medium;

[0115] The storage medium is used to store instructions;

[0116] The processor is configured to operate according to the instructions to perform the steps of the following method:

[0117] Get the pH setpoint,

[0118] The PH setting value is processed based on the generalized predictive control model with disturbance control;

[0119] Roll optimization based on processing results;

[0120] Feedback correction of pH setpoint based on optimization results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com