Cascade-pressurization hydrolysis reaction process and system for benzyl alcohol

A hydrolysis reaction, benzyl alcohol technology, applied in the directions of organic chemistry, preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of high dibenzyl ether by-product, large equipment size, and high equipment material requirements, and achieves Universality, low equipment corrosion rate, and the effect of reducing construction costs and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

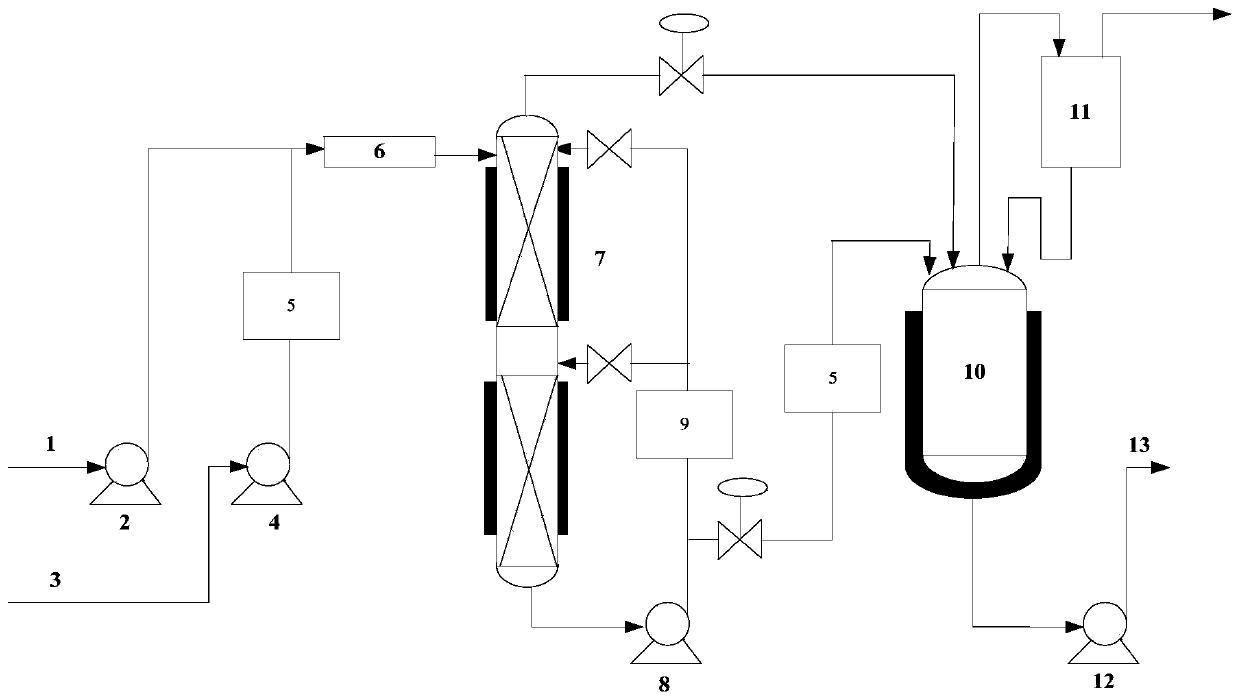

[0043] Such as figure 1 Shown, 11% soda ash solution (mass fraction) according to 0.57m 3 The feed amount per hour is pressurized to 0.3Mpa by the soda ash delivery pump and then sent to the soda ash preheater, and the material extracted by the tower reactor is preheated to 120°C.

[0044] Such as figure 1 Shown, benzyl chloride according to 0.14m 3The feed amount per hour, the soda ash solution pressurized and preheated by the benzyl chloride delivery pump enters the pipeline mixer, and is fully contacted and mixed in the pipeline mixer before being transported to the benzyl alcohol pressurized tower reactor. The reaction materials flow from top to bottom in the tower reactor, and the reaction residence time is 10 minutes. The reaction temperature is 135°C, and the reaction pressure is 0.25Mpa.

[0045] Such as figure 1 As shown, the carbon dioxide gas is decompressed by the pressure reducing valve and sent to the atmospheric pressure hydrolysis tank for buffering, and t...

Embodiment 2

[0049] A pressurized hydrolysis reaction system for benzyl alcohol, comprising: a preheater 5, a mixer 6, a pressurized tower reactor 7, a heater 9, a hydrolysis kettle 10, a condenser 12; the preheater 5, the mixer 6. The pressurized tower reactor 7, the hydrolysis kettle 10, and the condenser 12 are connected in sequence, and the liquid outlet at the bottom of the pressurized tower reactor 7 is connected with the liquid inlet of the pressurized tower reactor 7.

[0050] The above-mentioned structural design realizes the combination of pressurized and normal pressure reaction modes. After the reaction, the content of benzyl chloride in the hydrolyzed crude product can be reduced to 0.01%. Moreover, the present invention can be carried out under relatively mild conditions (120-150° C., 0.2-0.5 MPa), reducing the corrosion degree of materials to equipment under high temperature and high pressure, reducing reaction time and increasing reaction rate at the same time.

Embodiment 3

[0052] A pressurized hydrolysis reaction system for benzyl alcohol, comprising: a preheater 5, a mixer 6, a pressurized tower reactor 7, a heater 9, a hydrolysis kettle 10, a condenser 12; the preheater 5, the mixer 6. The pressurized tower reactor 7, the hydrolysis kettle 10, and the condenser 12 are connected in sequence, and the liquid outlet at the bottom of the pressurized tower reactor 7 is connected with the liquid inlet of the pressurized tower reactor 7.

[0053] The feed pipeline of soda ash is provided with the preheater 5, and the temperature of the lye is increased during preheating, thereby improving the subsequent hydrolysis reaction efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com