Supercritical fluid cascade extraction and oxidative degradation coupling combined process for treating oily sludge

A technology of supercritical fluid and combined process, which is applied in the direction of oxidation treatment of sludge, only multi-stage series refining and cracking process treatment, sludge treatment, etc., can solve the problem of low resource utilization rate of petroleum hydrocarbon components and the treatment process Problems such as high energy consumption and difficulty in continuous processing achieve high industrial application prospects, high degree of continuous processing, and efficient resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

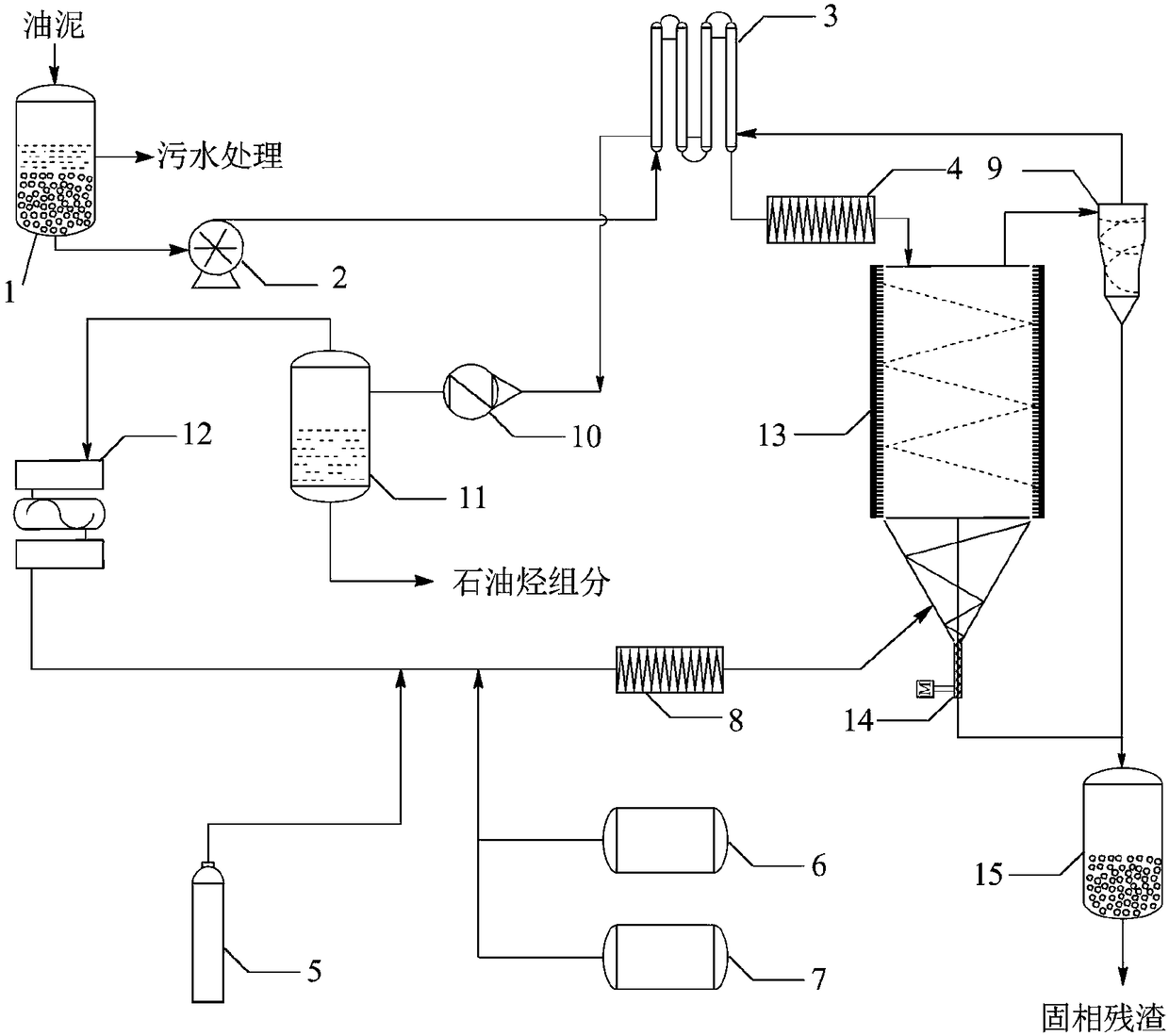

[0028] The oily sludge produced by crude oil extraction in an oil production plant in Shengli Oilfield has a moisture content of 40wt.% after pretreatment and dehydration, and a volume reduction rate of about 50%. The oily sludge enters the supercritical extractor 13 after being heated to 150° C. by the preheater 3 and the electric heater 4 .

Embodiment approach 2

[0030] The water content of the oily sludge produced by an offshore oil production platform in the Bohai Sea was reduced to 45wt.% after pretreatment and dehydration, and the volume reduction rate was about 40%. The oily sludge enters the supercritical reactor 13 after being heated to 200° C. by the preheater 3 and the electric heater 4 .

[0031] Preferably, methyl ethyl ketone peroxide is the oxidizing agent, and the supercritical reactor 13 is fed with the oxidizing agent from the storage tank 5, and the mass ratio of the regulating and controlling peroxygen is 250% (the mass ratio of the oxidizing agent to the oily sludge is 2.5:1), at a reaction pressure of 25 MPa, and a reaction temperature of 320 The oxidative degradation of petroleum hydrocarbon components is carried out under the condition of ℃. Then, n-pentane is selected as the main extraction agent, and the extraction agent is imported from the storage tank 6 to the supercritical reactor 13. The mass ratio of n-pen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com