Rectifying process and device of stable isotopes produced by neon gas

A stable isotope, neon gas technology, applied in the separation of different isotopic elements, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of low production capacity of neon isotope production equipment, reduce the amount of material transmission, overcome the difficulty of amplification, The effect of simplifying operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

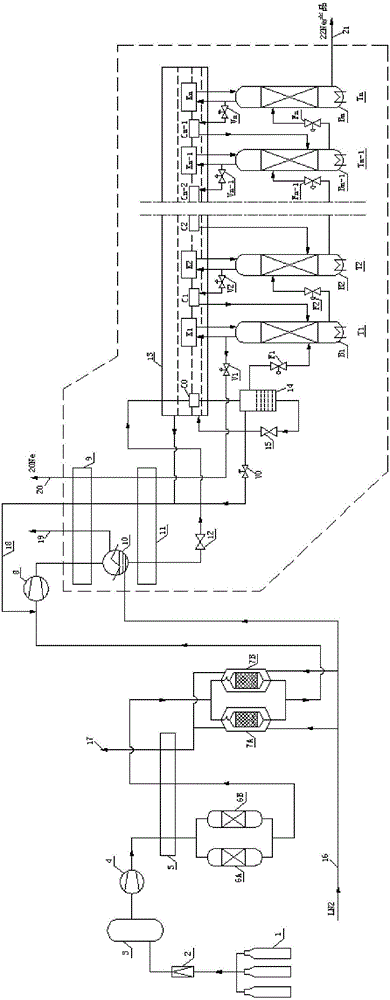

[0041] figure 1 It is a schematic diagram of the rectification process for preparing neon isotopes composed of n-stage cryogenic rectification towers in the present invention. The rectification device includes two major systems: a raw material purification system and a low-temperature rectification cascade system. The cryogenic rectification cascade system is all placed in a cold box, or placed in a multi-layer insulated vacuum container, and its vacuum degree reaches 5×10 -6 Pa or more.

[0042] Reference figure 1 In the process shown, after the high-purity natural neon gas is released from the natural high-purity neon gas cylinder 1, it is pressurized by the first compressor (membrane compressor) 4 to 20~20 through the pressure reducing valve 2 and the raw material buffer tank 3. 30bar, after being pre-cooled by the first heat exchanger 5, it passes through two parallel dewatering drying towers 6 (respectively equipped with dewatering drying columns 6A and 6B), and two parallel...

Embodiment 2

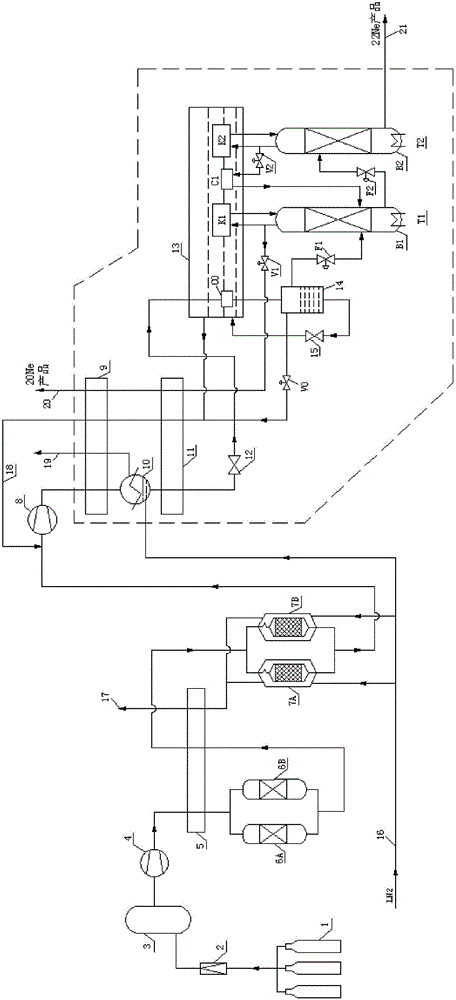

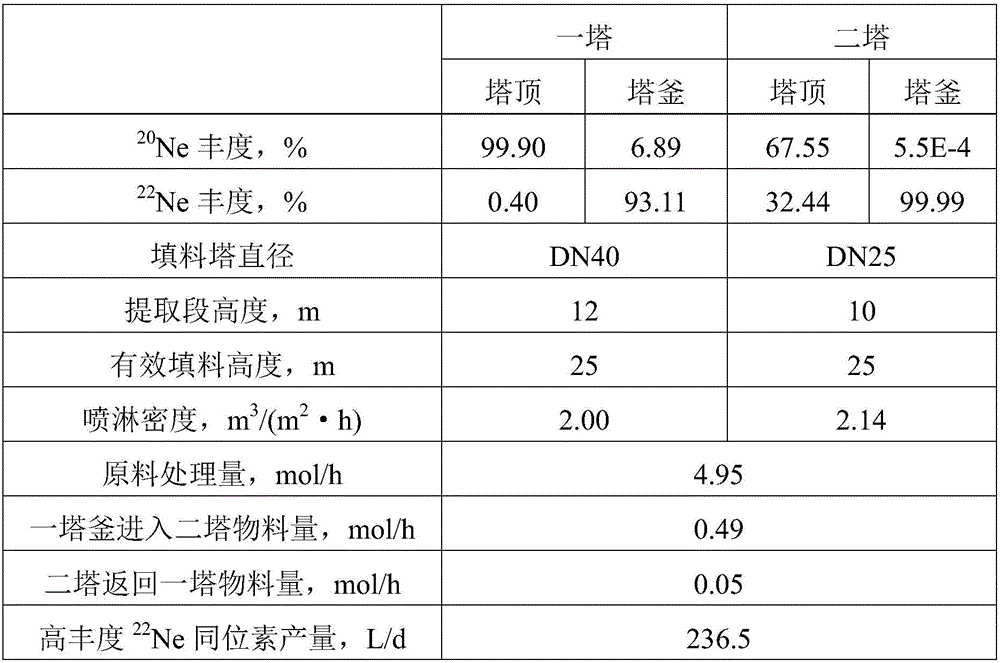

[0048] Such as figure 2 As shown, compared with Example 1, except for the neon isotope rectification device composed of two-tower cascade in this example, the rest are the same.

[0049] After the natural neon gas raw material is dried and dehydrated, adsorbed at low temperature to remove nitrogen and oxygen impurities, it enters the two-tower cascade assembly of low-temperature rectification. Both the first-stage distillation tower T1 and the second-stage distillation tower T2 are equipped with stripping sections. Part of the gas phase from the gas-liquid separator 14 is sent to the middle feed point of the first-stage rectification tower T1 through the medium-pressure throttle valve F1, and the materials in the first-stage rectification tower T1 are driven by the pressure difference through the regulating valve F2 is transported to the middle part of the second-stage distillation tower T2. Part of the material at the top of the tower is metered by the regulating valve V1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com