Evaluation method of oil-soluble scale inhibitor and tester

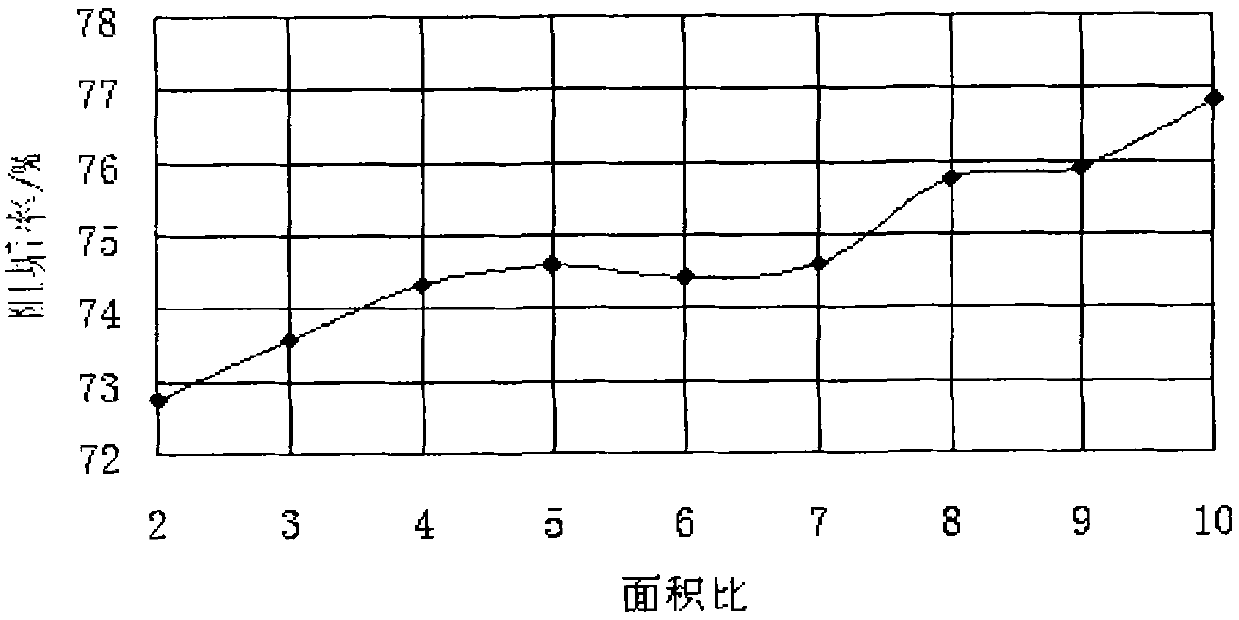

An evaluation method and test device technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of less dirt generation, less effective medium circulation, and difficulty in maintaining stable system pressure, so as to increase the area and reduce fouling The effect of reducing the amount of dirt, simplifying the way of generating dirt, and increasing the amount of dirt generated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The performance of the two slurry scale inhibitors was evaluated by simulating the operating conditions of the catalytic oil slurry at the bottom of the catalytic fractionation tower.

[0036] The test raw material is catalytic cracking oil slurry, which is a heavy test raw material that is prone to coking / fouling, and its properties are shown in Figure 4 .

[0037] (a), blank test:

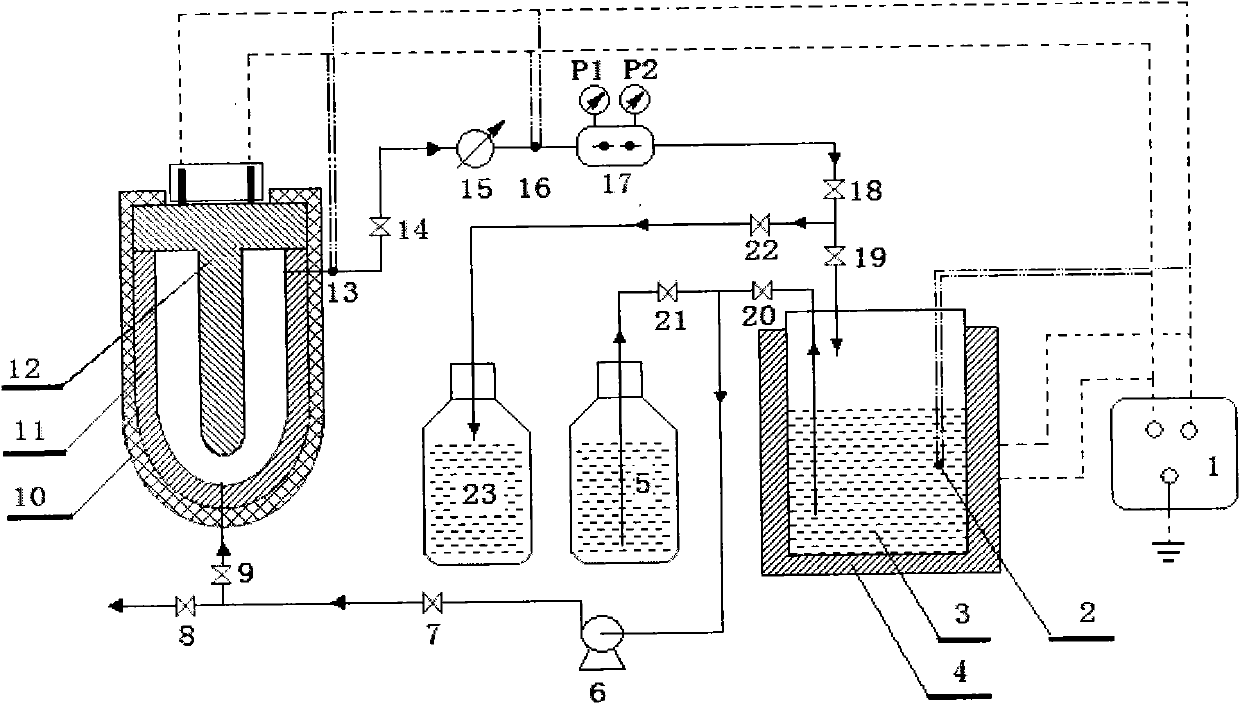

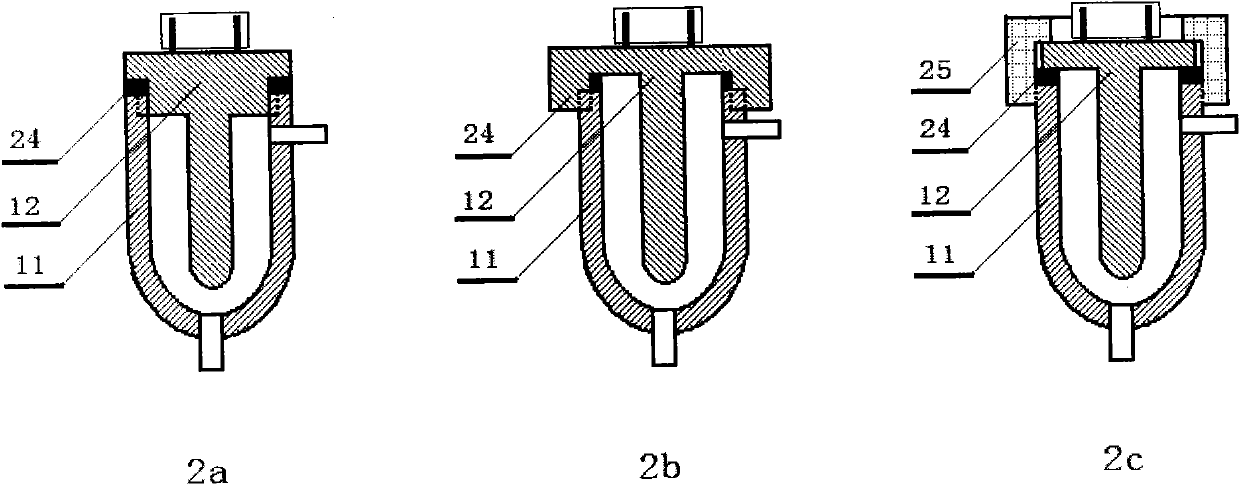

[0038]Select the circular cross-sectional area between the rod fouling test tube and the electric heating rod: the flow area of the connecting pipeline = 5.0: 1.0, weigh the total weight of the clean and dry dirt test tube 11 and the electric heating rod 12, and then connect them properly to the evaluation device. Add 2Kg of catalytic oil slurry into raw material tank 3, heat up to 110°C, and keep this temperature constant. In the washing oil bottle 5, add about account for the sherwood oil of its volume 80%. Close valves 8, 21 and 22, open valves 7, 9, 14, 18, 19 and 20, and turn o...

Embodiment 2

[0046] Simulate the operating conditions of the diesel hydrogenation raw material heat exchanger, and evaluate the diesel hydrogenation scale inhibitor C.

[0047] The diesel oil used in the test is a mixture of straight-run diesel oil:catalyzed diesel oil=1:1, which is a medium-quality test raw material with a small coking / fouling tendency, and its properties are shown in Figure 5 .

[0048] (c), blank test:

[0049] Select the annular cross-sectional area between the fouling test tube and the electric heating rod: the flow area=5.0: 1.0 of the connecting pipeline, weigh the total weight of the clean and dry dirt test tube 11 and the electric heating rod 12, and then properly connect it to the evaluation device. In raw material tank 3, add 2Kg mixed diesel oil, the temperature of raw material tank is kept on 60 ℃. In the washing oil bottle 5, add about account for the sherwood oil of its volume 80%. Close valves 8, 21, and 22, open valves 7, 9, 14, 18, 19, and 20, and tu...

Embodiment 3

[0055] Simulate the operating conditions of the coking gasoline hydrogenation raw material heat exchanger, and evaluate the gasoline hydrogenation antiscalant D.

[0056] The coking gasoline used in the test is a light test material with high coking / fouling ability, its properties are shown in Image 6 .

[0057] (e), blank test:

[0058] Select the annular cross-sectional area between the fouling test tube and the electric heating rod: the flow area=5.0: 1.0 of the connecting pipeline, weigh the total weight of the clean and dry dirt test tube 11 and the electric heating rod 12, and then properly connect it to the evaluation device. Add 2Kg of coker gasoline in raw material tank 3, the temperature of raw material tank is kept on 30 ℃. In the washing oil bottle 5, add about account for the sherwood oil of its volume 80%. Close valves 8, 21, and 22, open valves 7, 9, 14, 18, 19, and 20, and turn on the metering pump 6. When coked gasoline flows out from the return port of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com