Preparation method of cascade pore molecular sieve

A molecular sieve and stepped pore technology, which is applied in the directions of crystalline aluminosilicate zeolite, octahedral crystalline aluminosilicate zeolite, etc., can solve the problems such as the restriction of the improvement degree of molecular sieve diffusion capacity, and achieve the improvement of adsorption and diffusion capacity and wide applicability. , the effect of improving mass transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of preparation method of step hole MFI molecular sieve, its preparation method comprises the steps:

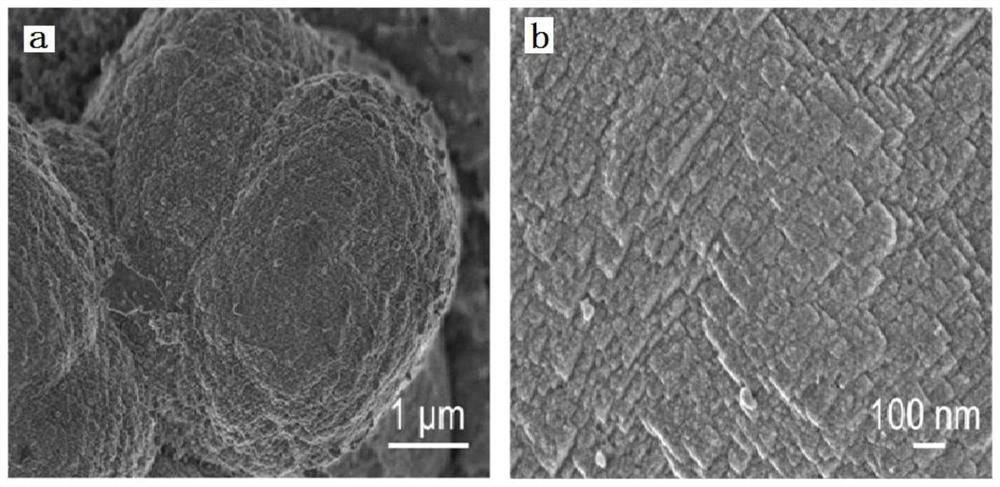

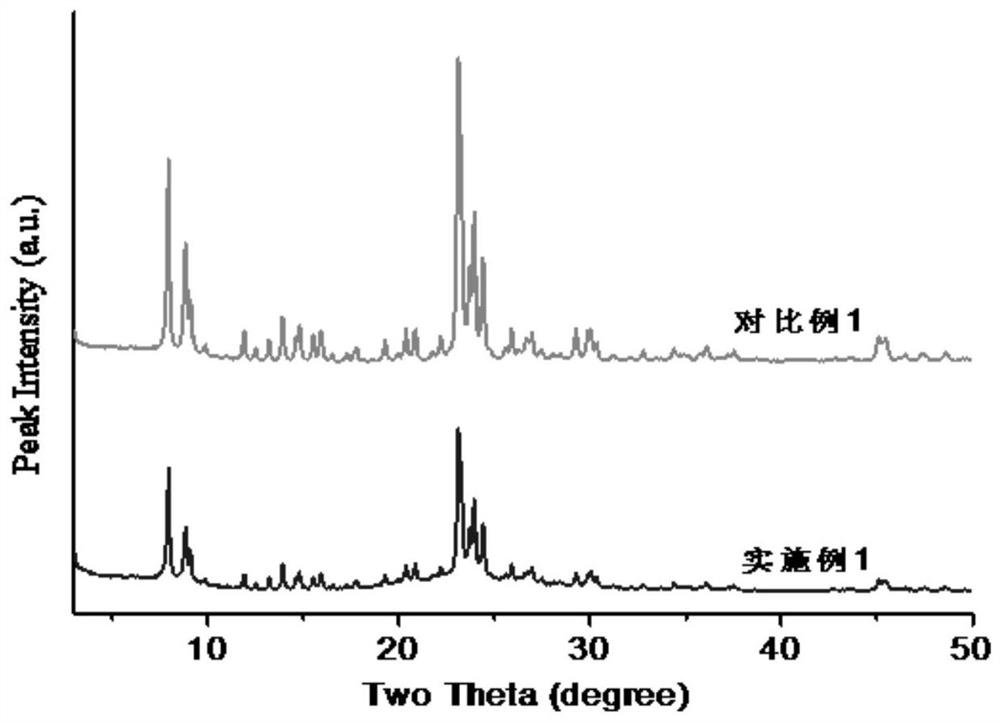

[0037] Synthetic raw material MFI molecular sieve: disperse 2.5g sodium hydroxide and 20.3g tetrapropylammonium hydroxide in 450g deionized water, stir at room temperature for 1h to fully dissolve and mix evenly; then add 3.75g aluminum nitrate nonahydrate to the solution , 52g tetraethyl orthosilicate, stirred at room temperature for 24 hours; after it was fully hydrolyzed and mixed uniformly, the molecular sieve precursor was transferred to a crystallization kettle with Teflon lining, placed in an oven, and heated at 170°C for 10 hours; then The sample was taken out, separated by filtration, fully washed with deionized water, and dried at 100°C for 12 hours to obtain the raw material MFI molecular sieve MFI-1 with a relative crystallinity of 76%;

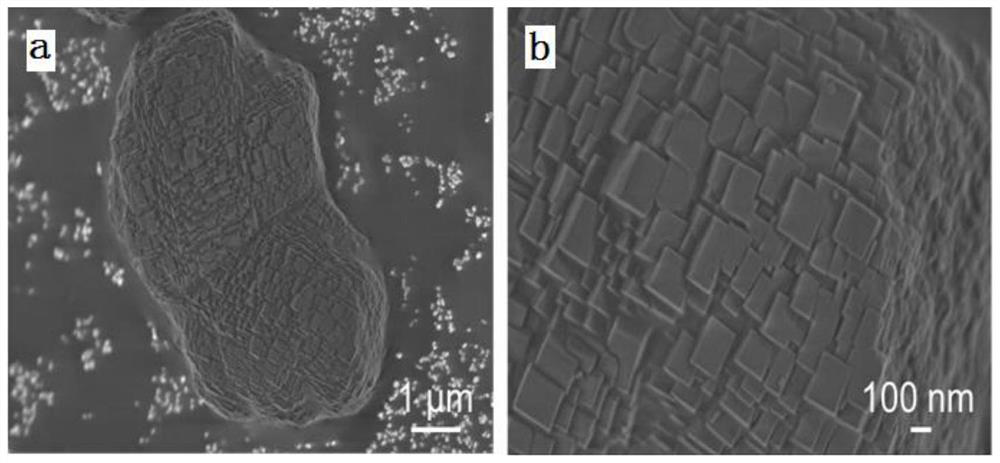

[0038]Preparation of step-pore MFI molecular sieve: Disperse the MFI-1 molecular sieve obtained in step 1) in 0.3 ...

Embodiment 2

[0040] A kind of preparation method of step hole MFI molecular sieve, its preparation method comprises the steps:

[0041] Synthetic raw material MFI molecular sieve: disperse 2.5g sodium hydroxide in 150g deionized water, stir at room temperature for 1 hour to fully dissolve and mix evenly; then add 3.75g aluminum nitrate nonahydrate and 52g tetraethyl orthosilicate to the solution, Stir at room temperature for 24 hours; after it is fully hydrolyzed and mixed evenly, add 50 mg of MFI molecular sieve seed crystals to it, stir for 30 minutes to make it evenly mixed, transfer the molecular sieve precursor to a Teflon-lined crystallization kettle, and place it in an oven. Heat at 170°C for 8 hours; then take out the sample, filter and separate the sample, wash it thoroughly with deionized water, and dry it at 100°C for 12 hours to obtain the raw material molecular sieve MFI-2 with a relative crystallinity of 78%;

[0042] Preparation of step-pore MFI molecular sieve: Disperse the...

Embodiment 3

[0044] A preparation method of step hole ultra-stable Y-type molecular sieve, the preparation method comprising the following steps:

[0045] Synthetic raw material Y type molecular sieve: get 20.60g sodium metaaluminate solution (21.0wt%Na 2 O, 3.20wt% Al 2 o 3 ) and 20.90g water glass (28.45wt% SiO 2 ,8.89wt%Na 2 O) Disperse it evenly in 8.60g deionized water, stir for 30min and wait for it to be fully mixed, then let it stand for aging for 16h; take 50g of the above mixture, 75.86g of water glass, and 16.88g of sodium metaaluminate evenly dispersed in 25g of deionized In water, add 51.05g aluminum sulfate solution (7.60wt% Al 2 o 3 ), continue stirring for 1 hour, place the obtained gel in a Teflon-lined crystallization kettle and heat it at 98°C for 10 hours; then take out the sample, filter and separate the sample, wash it thoroughly with deionized water, and dry it at 100°C for 12 hours , obtain raw material molecular sieve Y-1, its relative crystallinity is 72%; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com