Production method of high-abundance boron-11 isotope

A production method and isotope technology, applied in the direction of boron halides, boron halide compounds, etc., can solve the problems of reduced operability and stability, backward technology, and unfavorable stable production of boron isotopes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

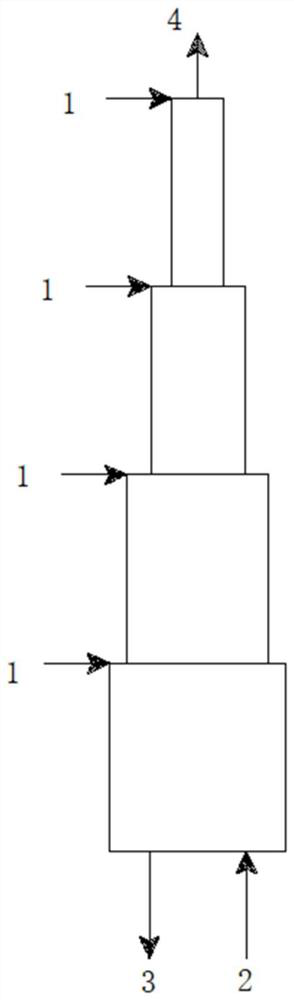

[0050] The complexing agent adopts anisole, enters from the complexing agent inlet 1 (comprising a top inlet and three middle inlets) of the gas-liquid exchange device, and boron trifluoride enters from the boron trifluoride raw material inlet 2 ( That is, the bottom entrance of the device) enters. The boron trifluoride-anisole complex is extracted from the bottom outlet 3 of the gas-liquid exchange device, and the boron trifluoride rich in boron-11 is extracted from the boron-11 product outlet 4 (i.e. its top outlet) of the gas-liquid exchange device. ) mining.

[0051] The flow change of boron trifluoride in the gas-liquid exchange device and the location of the inlet and outlet of the material are as follows: figure 1 As shown, the molar flow of boron trifluoride in the device from bottom to top gradually decreases, and the flow of anisole increases gradually. The molar flow rate of the boron trifluoride raw material is 5 kmol / h, and the incoming molar flow rates of aniso...

Embodiment 2

[0055] The complexing agent adopts methyl ether, enters from the complexing agent inlet 1 (comprising a top inlet and two middle inlets) of the gas-liquid exchange device, and boron trifluoride enters from the boron trifluoride raw material inlet 2 of the gas-liquid exchange device (i.e. bottom inlet of the device) to enter. The boron trifluoride-methyl ether complex is extracted from the bottom outlet 3 of the gas-liquid exchange device, and the boron trifluoride-methyl ether complex rich in boron-11 is extracted from the boron-11 product outlet 4 of the gas-liquid exchange device (Here is the middle outlet) mining, the middle outlet is located between the top complexing agent inlet 1 and the first middle complexing agent inlet 1 from top to bottom.

[0056] From bottom to top, the molar flow rate of boron trifluoride in the gas-liquid exchange device gradually decreases, and the flow rate of methyl ether gradually increases. The molar flow rate of the boron trifluoride raw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com