Method for regulating multistage-cascade induction electro-Fenton by graded addition of H2O2 on basis of pH indication

A technology of H2O2 and induction electricity, applied in the direction of sterilization/microdynamic water/sewage treatment, etc., can solve the problems of decreased treatment efficiency of Fenton technology, waste of input materials, lack of scientific basis, etc., so as to save project implementation costs and improve Utilize efficiency, optimize the effect of implementation parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

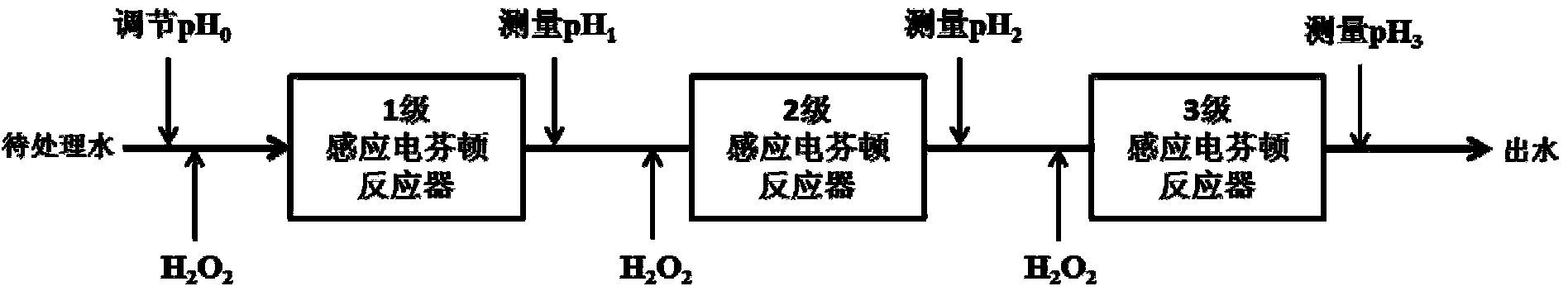

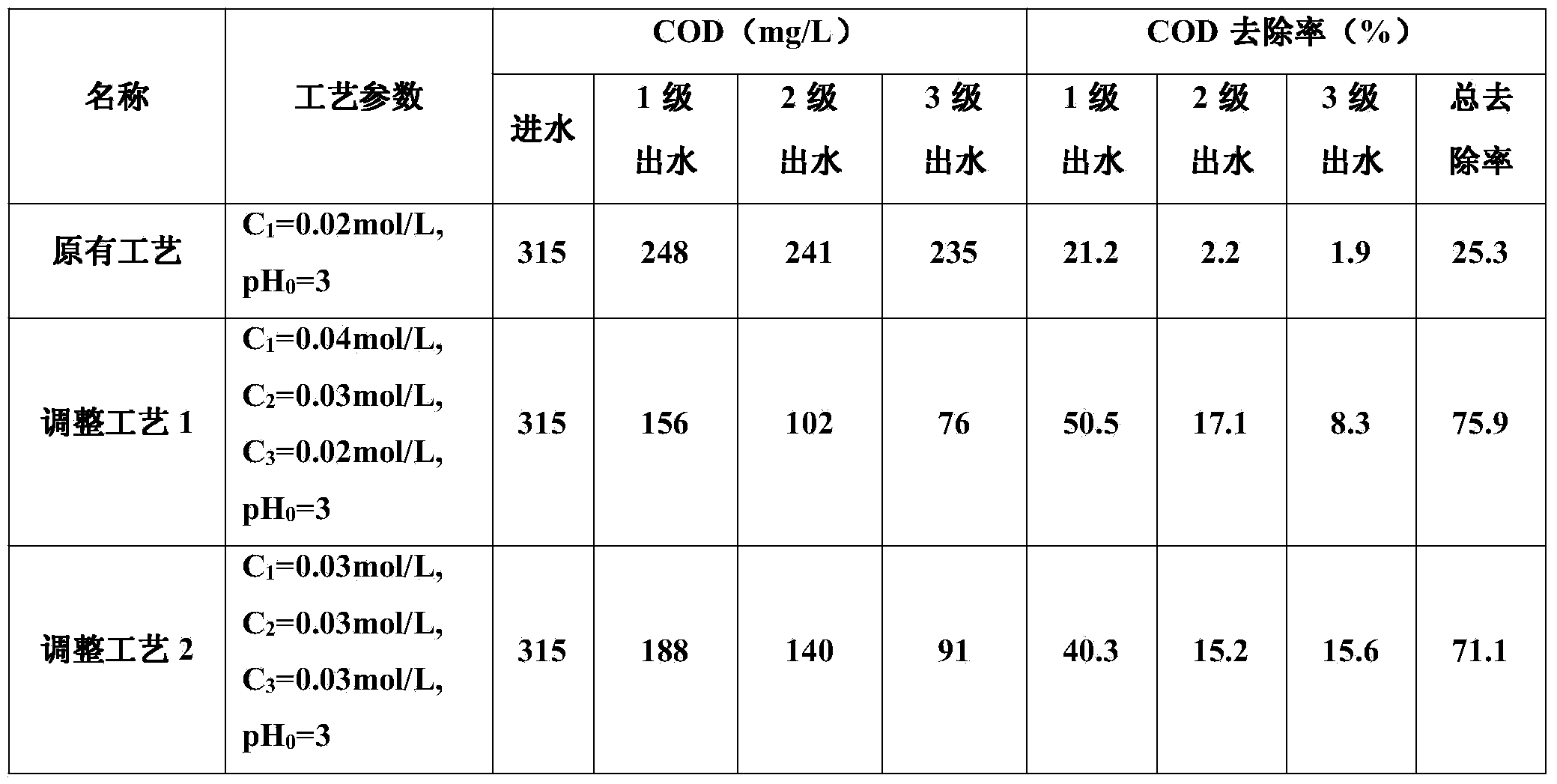

[0034] Wastewater from an enterprise (COD about 315mg / L, pH about 6.5) such as figure 1 As shown, the three-stage homogeneous induction electro-Fenton process is adopted, and the residence time of the designed reactor is 30min. H 2 o 2 Concentration C 1 Adjust to 0.02mol / L, pH 0 After being adjusted to 3, it passes through the first-stage induction electric Fenton reactor and then enters the second and third-stage reactors in turn. After connecting the external power supply and running stably for 30 minutes, the pH 0 to pH 3 They were 3, 4.2, 5.3 and 6.5 respectively, and the COD value of the effluent was 235mg / L, which did not meet the third-level standard for wastewater discharge (COD is less than or equal to 100mg / L). found to meet the pH 0 +11 2 n Conditions, take measures 1 to make the following adjustments: At the same time, add H 2 o 2 , such that C 1 0.04mol / L, C 2 0.03mol / L, C 3 It is 0.02mol / L. After adjusting and running for 30 minutes, the pH 0 to pH ...

Embodiment 2

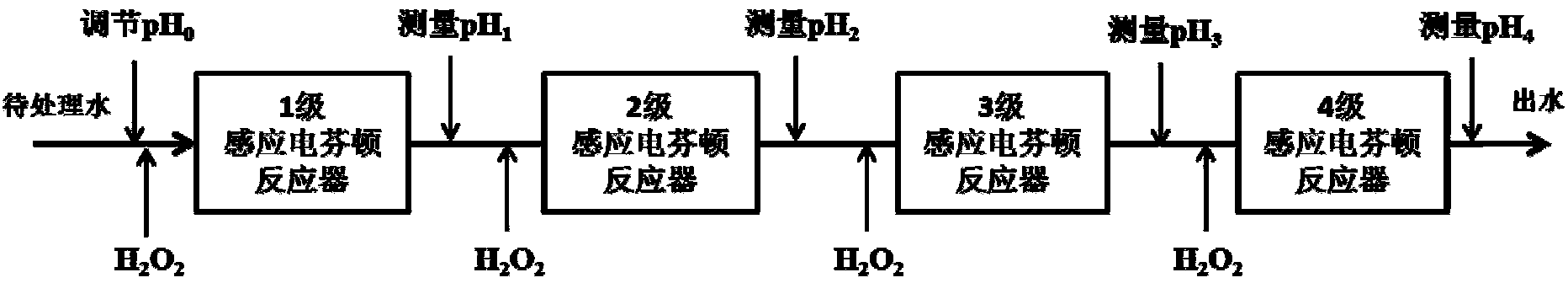

[0038] A chemical factory produces biochemical effluent (COD value is about 450mg / L, pH is about 6.6) using such as figure 2 The shown 4-stage homogeneous induction electro-Fenton process treatment, the design reactor residence time is 20min, the influent pH 0 Adjust to 3, and add H at the same time before the 4th grade reactor 2 o 2 , so that C 1 to C 4 The concentration is 1mol / L. After connecting the external power supply and running stably for 20 minutes, the pH 1 to pH 4 They were 3, 4.1, 5.2, 5.9 and 6.6 in turn, and the COD value of the final effluent was reduced to 180mg / L, but it still did not meet the emission requirements. found to meet the pH 0 +11 2 n Conditions, take measures 1 to adjust as follows: at the same time, adjust the H 2 o 2 Dosage, so that C1 1.5mol / L, C 2 1.5mol / L, C 3 1.5mol / L and C 4 It is 1.5mol / L. After adjusting and running for 20 minutes, the COD value of the effluent is 88mg / L, and the pH 0 to pH 3 3, 3.3, 3.6 and 3.9 respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com