Electrochemical oxidation system capable of automatically inhibiting and removing scale and treatment process

An oxidation system, electrochemical technology, applied in electrochemical water/sewage treatment, special treatment targets, water/sewage treatment, etc. Inhibit the scaling rate and other problems to achieve the effect of improving the efficiency of oxidation treatment, reducing the risk of misoperation, and improving the effect of operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

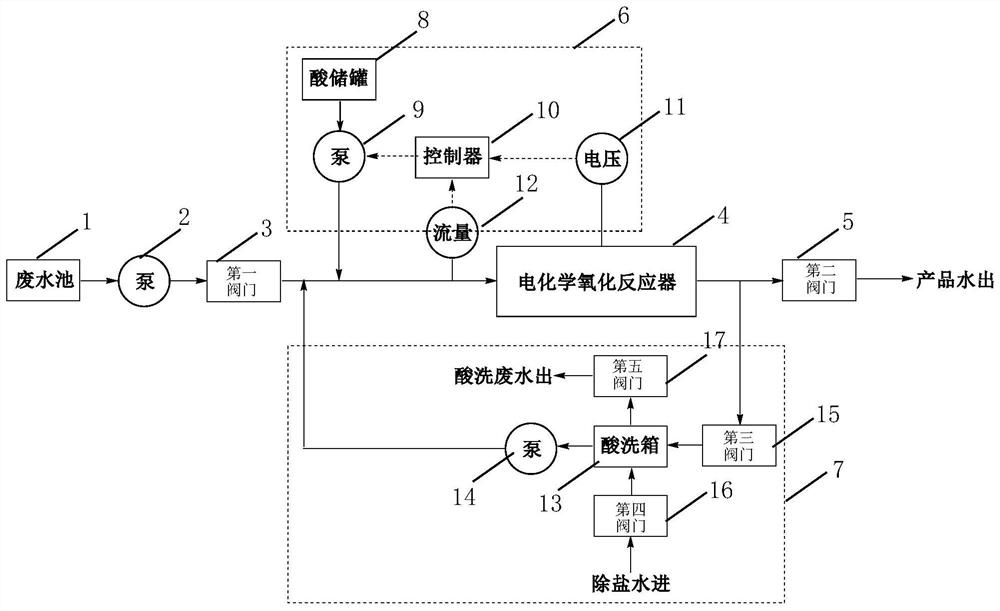

[0036] Embodiment 1 of the present application provides a method such as figure 1 The automatic scale suppression and descaling electrochemical oxidation system shown:

[0037]It is equipped with a waste water pool 1, an inlet pump 2, a first valve 3, an electrochemical oxidation reactor 4, and a second valve 5; it is also equipped with a voltage feedback automatic scale suppression system 6 and a voltage feedback automatic pickling system 7; Scale system 6 includes acid storage tank 8, electromagnetic metering pump 9, controller 10, voltmeter 11, flow meter 12 and supporting pipelines; voltage feedback automatic pickling system 7 includes pickling tank 13, pickling pump 14 and supporting pipes road; the outlet of the waste water pool 1 is connected to one end of the water inlet pump 2, and the other end of the water inlet pump 2 is connected to the electrochemical oxidation reactor 4 through the water inlet pipe, and the water inlet pipe between the water inlet pump 2 and the...

Embodiment 2

[0039] On the basis of Embodiment 1, Embodiment 2 of this application provides the treatment process of the automatic scale suppression and descaling electrochemical oxidation system in a certain coal-fired power plant in Embodiment 1:

[0040] A coal-fired power plant uses electrochemical oxidation to treat ammonia nitrogen wastewater in the plant, and oxidizes ammonia nitrogen pollutants into nitrogen. The hardness of the treated ammonia nitrogen wastewater is relatively high, the concentration of calcium ions fluctuates in the range of 100mg / L-1000mg / L, and the concentration of magnesium ions fluctuates in the range of 30mg / L-300mg / L. In the original electrochemical oxidation process, adjust the pH of the influent to 5.5-6.0, and control the current density of the plate to 40-45A / m 2 , the flow rate is 30t / h. The shell of the electrochemical oxidation reactor is made of transparent plexiglass, and the fouling on the electrode surface can be directly observed. During the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com