System and method for real-time tracking and quality tracing of procedure logistics in discrete manufacturing

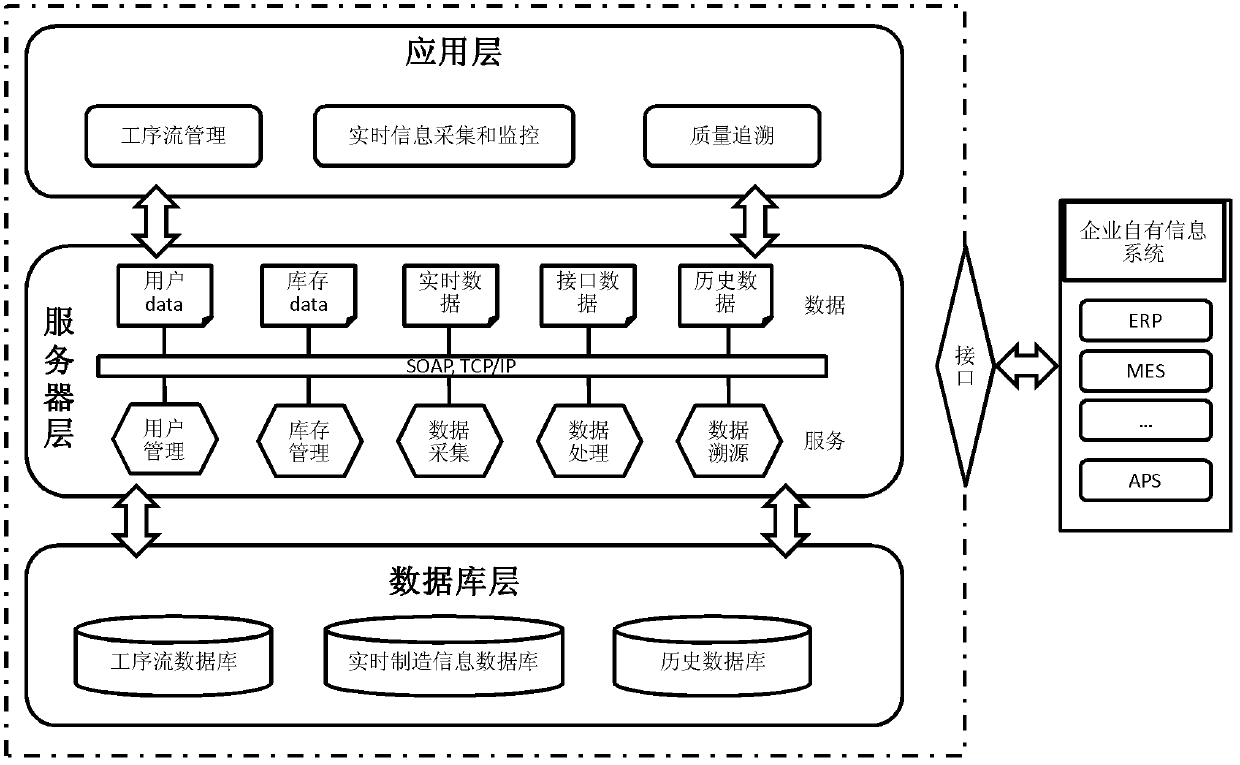

A real-time tracking and process technology, applied in the field of logistics information and radio frequency, can solve the problems of difficult acquisition of real-time information data, quality traceability, and difficulty of real-time logistics tracking in discrete manufacturing workshops, so as to reduce information sluggishness, improve transparency, increase The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

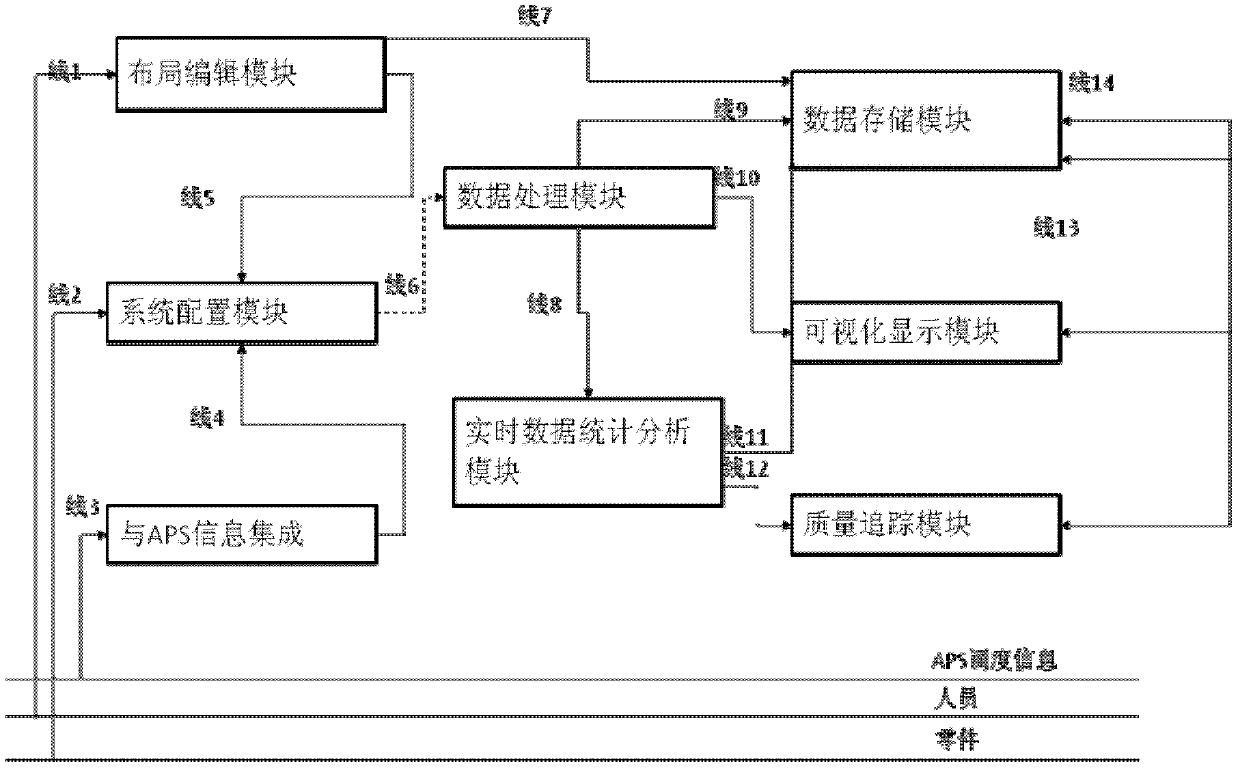

[0041] The present invention is described in further detail below in conjunction with accompanying drawing:

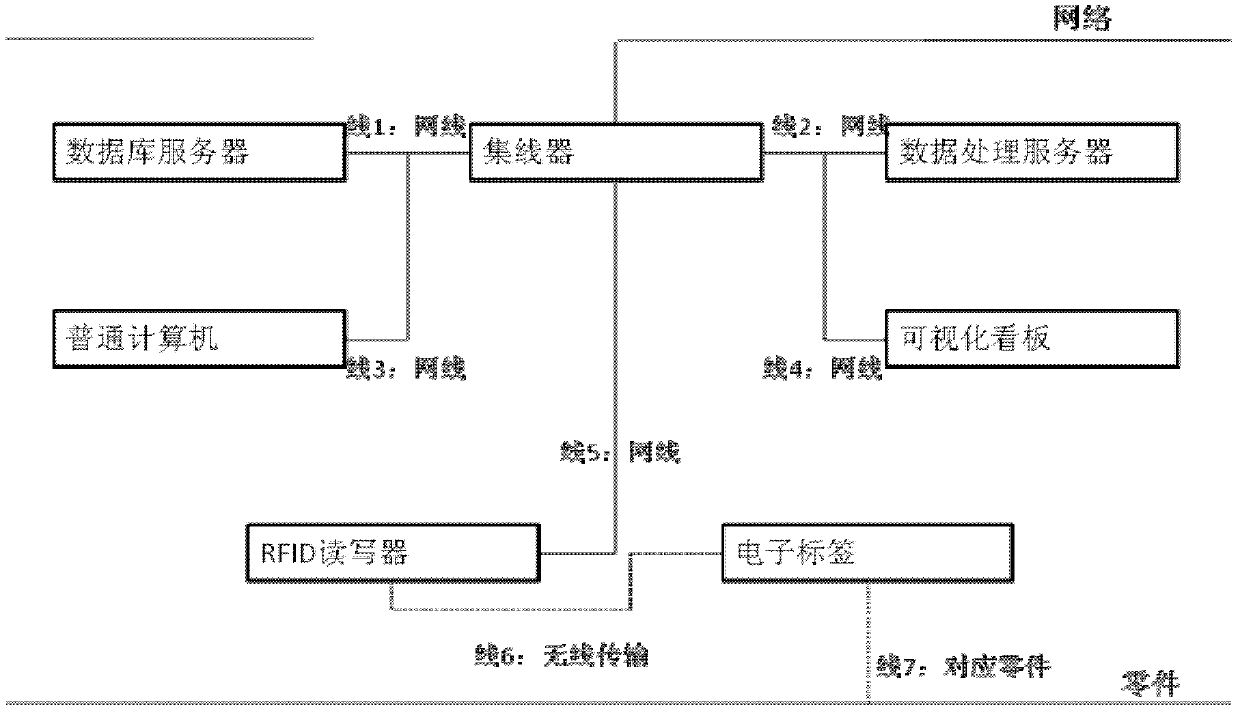

[0042] see figure 2 : the system of the present invention to the real-time tracking of discrete manufacturing process logistics and trace quality, comprising hub and the computer connected with hub by network cable, database server, data processing server, visual kanban, RFID label and RFID reader-writer.

[0043] RFID reader: The RFID reader is used to read and write the information in the RFID tag wirelessly, and transmit it to the data processing server through the hub for processing and storage in the database server. In the preferred embodiment of the present invention, an RFID reader with a radio frequency of 915 MHz is used.

[0044] RFID tags: Write part information, personnel information and drawing information in the RFID tags, and bind each RFID tag with its corresponding parts, personnel or drawings, and be read by the RFID reader. The RFID tag adopts a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com