Backpressure monitoring system and method of hydraulic support

A technology of hydraulic support and monitoring system, which is applied to mine roof support, earth-moving drilling, mining equipment, etc., can solve the problems of inability to grasp the distribution of force, shorten the life of support, safety accidents, etc., and achieve convenient control of hydraulic support action, The results are intuitive and easy to understand, and the effect of improving the degree of transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

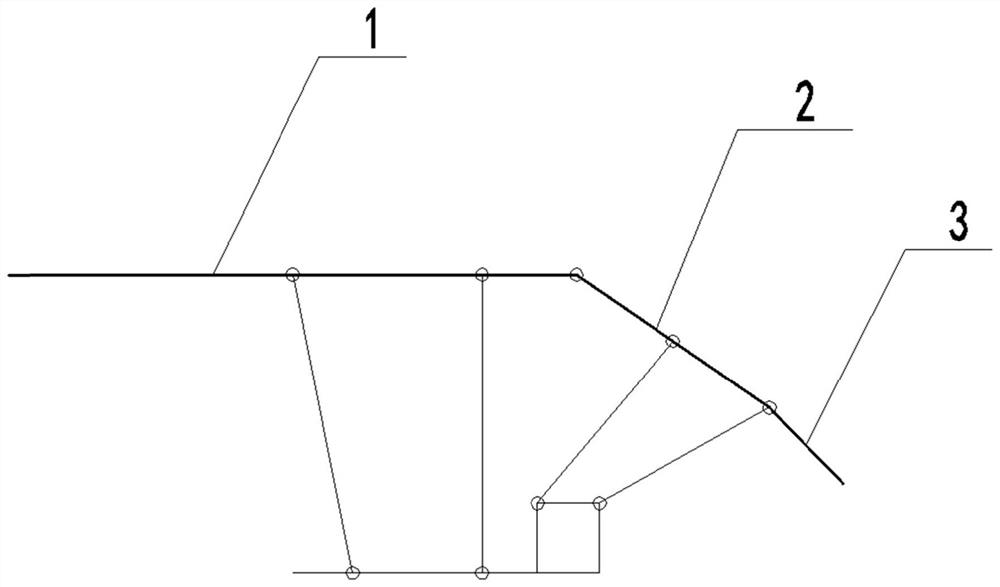

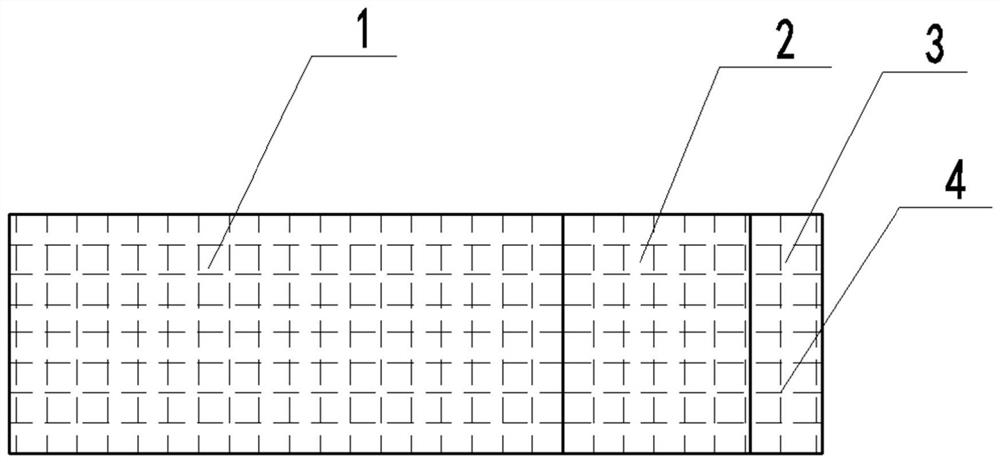

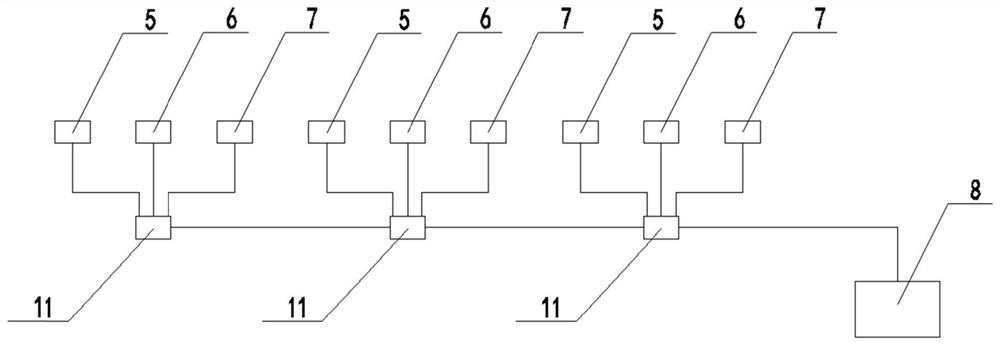

[0058] Such as figure 1 , figure 2 and image 3 As shown, a working face adopts four-column low-position top-coal caving support. In the hydraulic support design stage, the top beam 1, cover beam 2, and tail beam 3 are designed with uniformly arranged depressions. After the hydraulic support is manufactured, pressure sensors 4 are installed in the depressions. On the hydraulic support, a data acquisition device 5 in the top beam area of the hydraulic support, a data acquisition device 6 in the shield beam area, and a data acquisition device 7 in the tail beam area are installed, and the above three area data acquisition devices are connected to the back pressure data acquisition and analysis device of the hydraulic support 11. Adjacent hydraulic support back pressure data acquisition and analysis devices are connected to each other, and the data is transmitted to the hydraulic support back pressure monitoring host computer 8 in the monitoring center. The hydraulic support ...

Embodiment 2

[0060] Such as figure 1 , figure 2 and image 3 As shown, a working face adopts a four-column fully mechanized mining hydraulic support. This type of hydraulic support has no tail beam 3. In the design stage of the hydraulic support, the top beam 1 and the cover beam 2 are designed with uniformly arranged depressions. After the hydraulic support is manufactured, the pressure sensor 4 is installed. The hydraulic support is equipped with a hydraulic support top beam area data acquisition device 5 and a shield beam area data acquisition device 6. The above two area data acquisition devices are connected to the hydraulic support back pressure data acquisition and analysis device 11, and the adjacent hydraulic support back pressure data acquisition The analysis devices 11 are connected to each other and transmit the data to the hydraulic support back pressure monitoring host computer 8 in the monitoring center. The hydraulic support back pressure monitoring host computer 8 is equ...

Embodiment 3

[0062] Such as figure 1 , figure 2 and Figure 4 As shown, a working face adopts a four-column low-level top-coal caving support. This type of support is equipped with a hydraulic support electro-hydraulic controller 10. In the hydraulic support design stage, the top beam 1, cover beam 2, and tail beam 3 are designed with uniformly arranged depressions. After the manufacture is completed, the pressure sensor 4 is installed in the recessed part, and the data acquisition device 5 in the top beam area of the hydraulic support, the data acquisition device 6 in the shield beam area, and the data acquisition device 7 in the tail beam area are installed on the hydraulic support. Connected to the hydraulic support back pressure data acquisition and analysis device 11, the hydraulic support back pressure data acquisition and analysis devices are connected to each other, and the data is transmitted to the hydraulic support back pressure monitoring host computer 8 of the monitoring c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com