Firearms projectile

a projectile and firearm technology, applied in the field of projectiles, can solve problems such as interface rupture, and achieve the effects of reducing heat buildup, reducing contact area, and reducing barrel friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

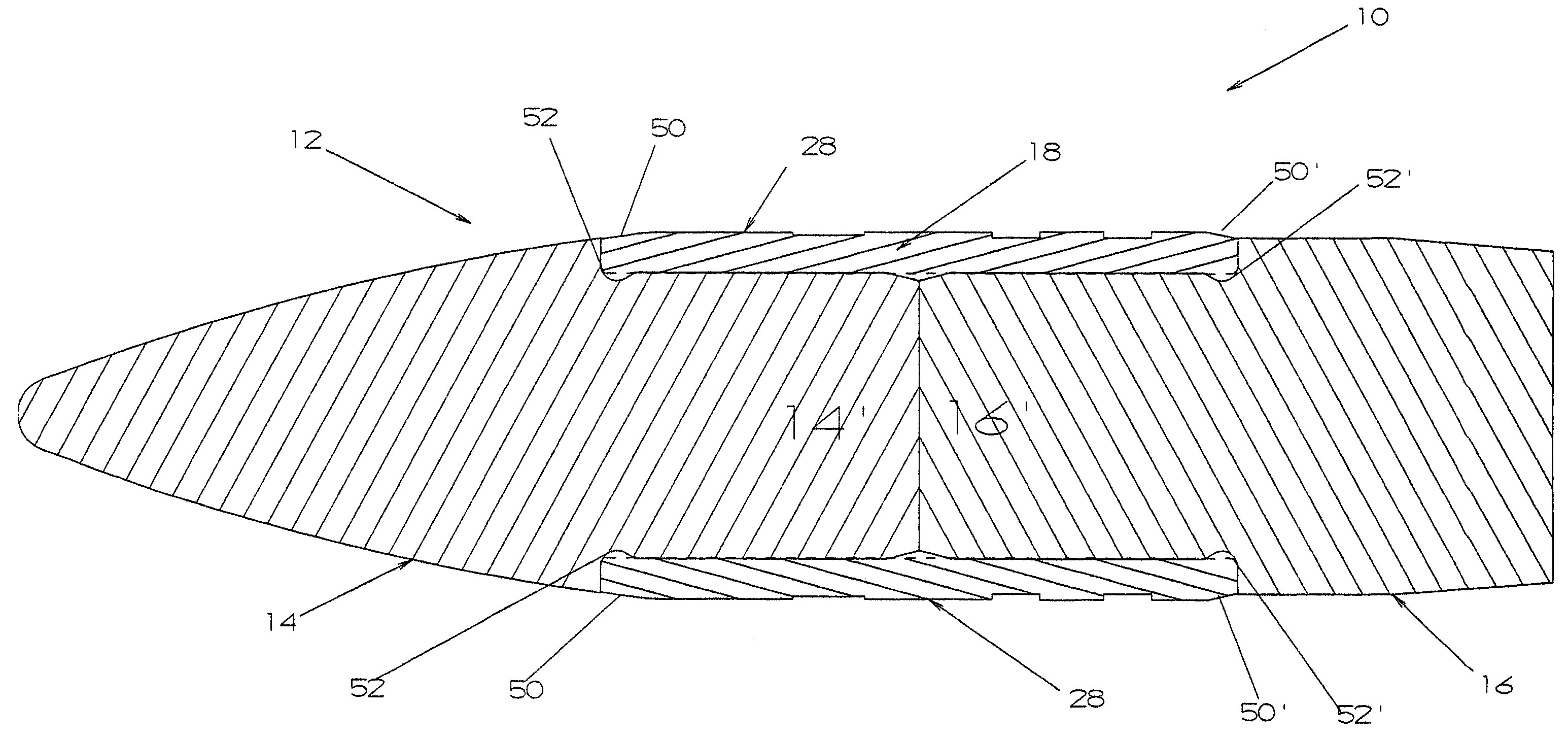

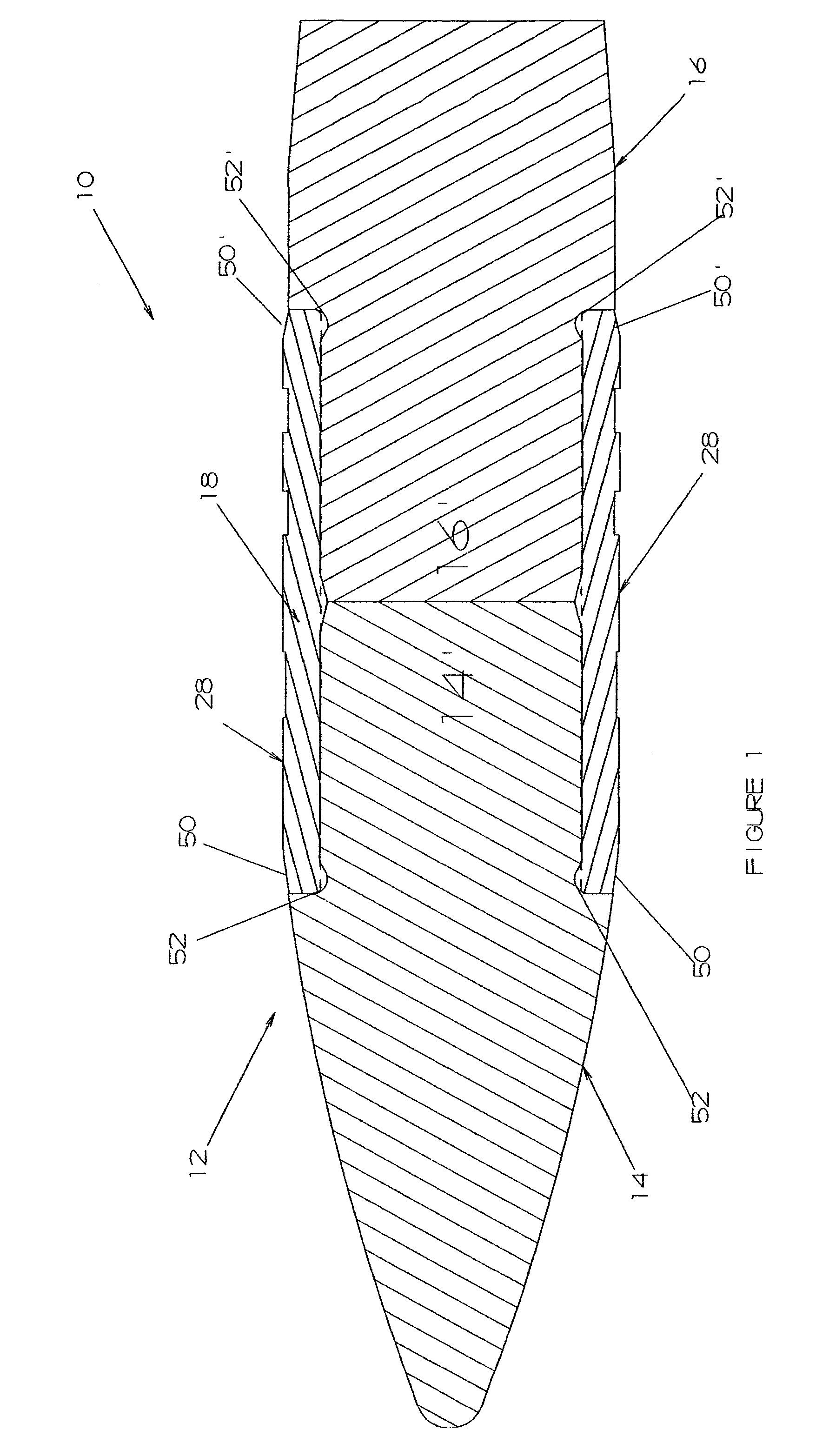

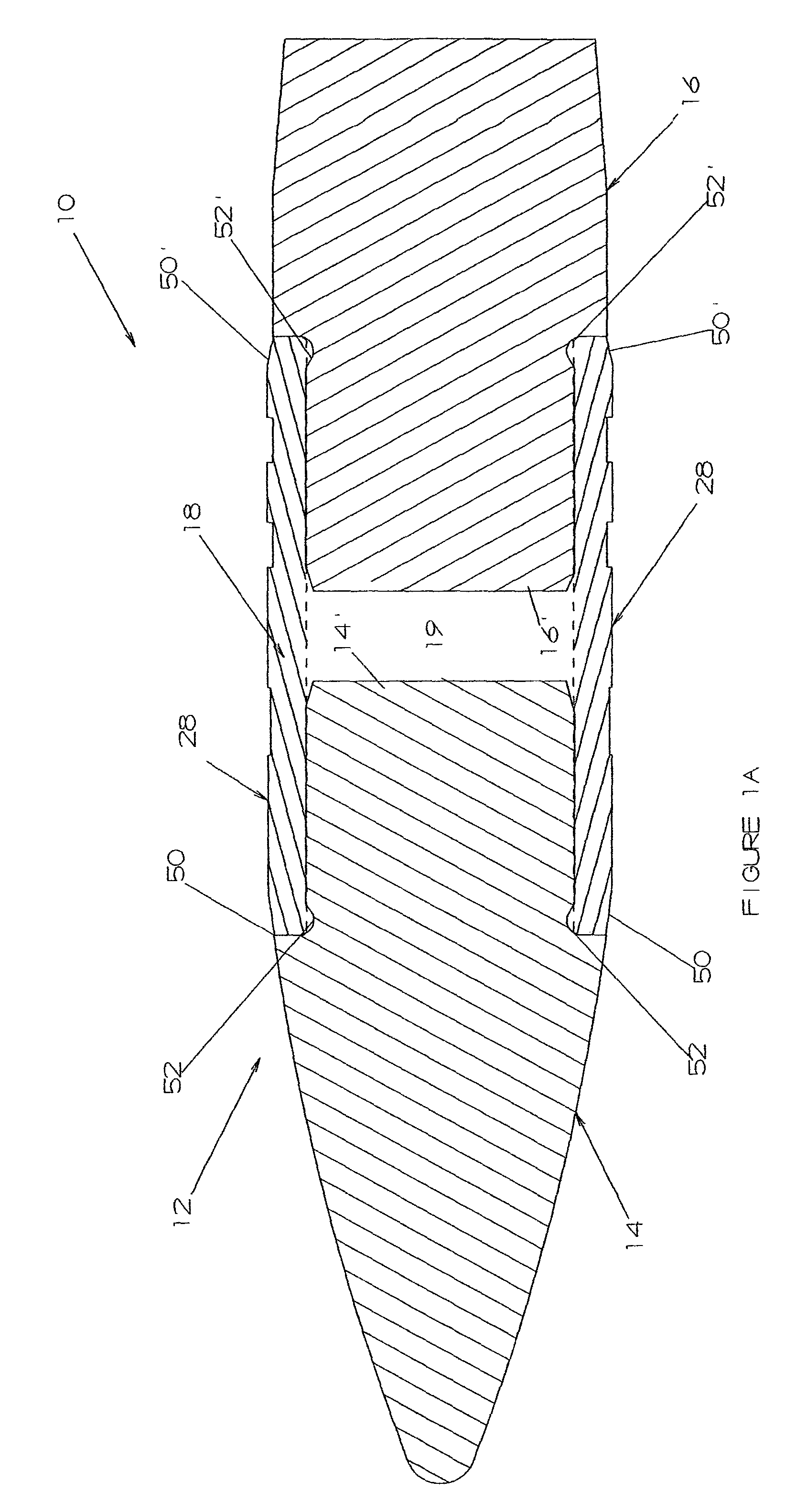

[0028]As shown in the accompanying Figures, the present invention is directed to a projectile generally indicated as 10 of the type structured to be fired from a firearm. More specifically, the projectile 10 includes a body, generally indicated as 12, which comprises a nose portion 14 and a tail portion 16 shown in detail in FIGS. 2, 3, 5, and 6 respectively. In addition, the projectile body 12 includes an interface 18, shown in detail in FIGS. 4 and 7, disposed intermediate the opposite ends of the projectile body 12 in interconnecting relation to the head portion 14 and the tail portion 16 as demonstrated in FIG. 1.

[0029]Structural features associated with one or more preferred embodiments of the projectile 10 include the nose and tail portions 14 and 16 respectively, formed of high density metal matrix composites, metals, alloys, or ceramics. More specifically, the nose and tail portions 14 and 16 can each be formed from a material which contains one or more of the following: alu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com