Method for forming protective layers on surface of object and product with protective layers formed on surface

A technology of object surface and protective layer, which is applied in the direction of surface coating liquid device, pretreatment surface, coating, etc., can solve the problem of poor bonding force between the protective polymer layer and the object surface, so as to improve the bonding force and improve the The effect of protecting the lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0114] 100 transistors were placed in the plasma chamber, the chamber was evacuated to a base pressure of 3-10 mTorr, and then helium gas was passed into the chamber at 20 sccm until the pressure reached 80 mTorr. Continuous power plasma was then induced using RF at 13.56 MHz, 300 W for 5 minutes.

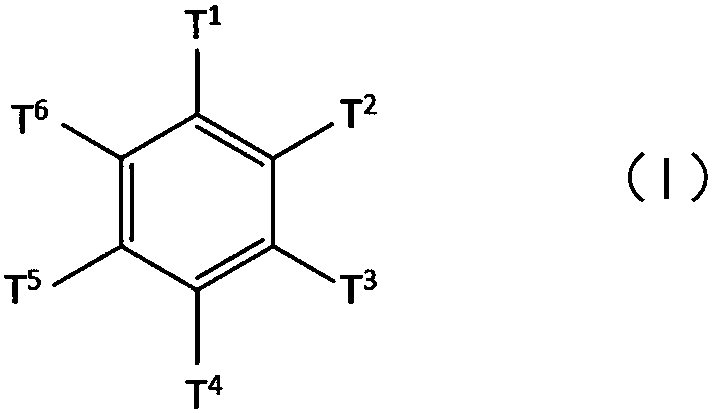

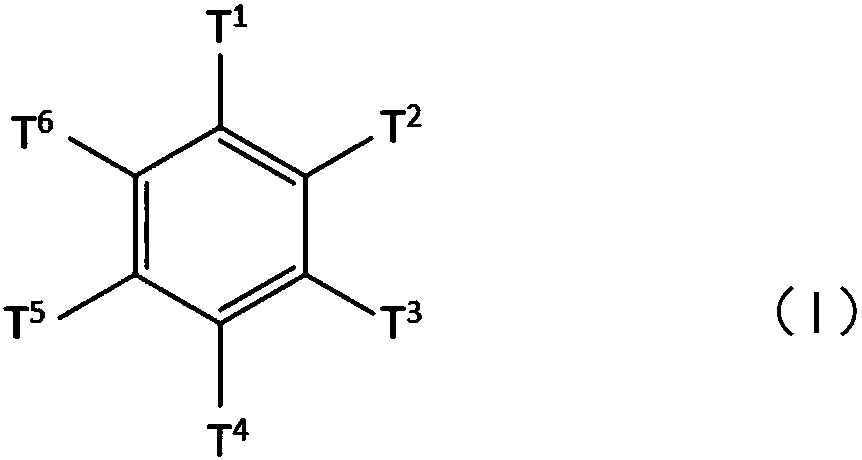

[0115] Next, p-trifluorotoluene vapor was introduced into the chamber at a rate of 120 mg / min, and the plasma was switched to the following pulsed plasma: peak power 100 W, frequency 50 Hz, duty cycle 5 %. The ditrifluorotoluene ionizes and reacts with itself to form a continuous and uniform first protective layer on the surface of the transistor. After 15 minutes, the plasma power was turned off and the p-trifluorotoluene vapor supply was stopped.

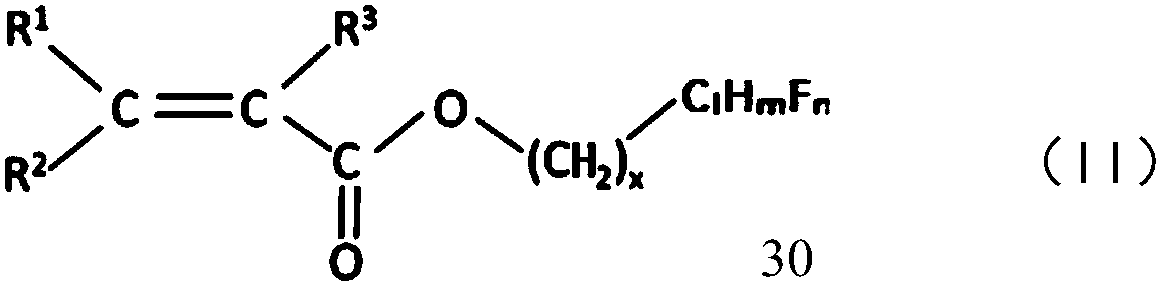

[0116] Maintain the vacuum in the chamber, introduce 1H,1H,2H,2H-perfluorodecyl acrylate vapor into the chamber at a rate of 120 mg / min, and switch the plasma to the following pulsed plasma: peak The power is 150W, the frequency is ...

Embodiment 2

[0119] 100 transistors were placed in the plasma chamber, the chamber was evacuated to a base pressure of 3-10 mTorr, and then helium gas was passed into the chamber at 20 sccm until the pressure reached 80 mTorr. Continuous power plasma was then induced using RF at 13.56 MHz, 300 W for 5 minutes.

[0120] Next, p-ditrifluorotoluene vapor was introduced into the chamber at a rate of 120 mg / min, and the plasma was switched to the following pulsed plasma: peak power 100 W, frequency 100 Hz, duty cycle 5 %. The ditrifluorotoluene ionizes and reacts with itself to form a continuous and uniform first protective layer on the surface of the transistor. After 15 minutes, the plasma power was turned off and the p-trifluorotoluene vapor supply was stopped.

[0121] Maintain the vacuum in the chamber, introduce hexafluoropropylene vapor into the chamber at a rate of 120 mg / min, and switch the plasma to the following pulsed plasma: the peak power is 100W, the frequency is 100Hz, and the...

Embodiment 3

[0125] 100 knitted gloves were placed in the plasma chamber, the chamber was evacuated to a base pressure of 3-10 mTorr, and then nitrogen gas was passed into the chamber at 20 sccm until the pressure reached 80 mTorr. Continuous power plasma was then induced using RF at 13.56 MHz, 300 W for 5 minutes.

[0126] Next, 1,2,4-trimethylbenzene vapor was introduced into the chamber at a rate of 120 mg / min, and the plasma was switched to the following pulsed plasma: peak power 100 W, frequency 50 Hz, duty cycle The ratio is 25%. The 1,2,4-trimethylbenzene ionizes and reacts with itself to form a continuous and uniform first protective layer on the surface of the transistor. After 15 minutes, the plasma power was turned off and the supply of 1,2,4-trimethylbenzene vapor was stopped.

[0127] Maintain the vacuum in the chamber, introduce 1H,1H,2H,2H-perfluorodecyl acrylate vapor into the chamber at a rate of 120 mg / min, and switch the plasma to the following pulsed plasma: peak The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com